A pipeline muffler device capable of recovering noise energy

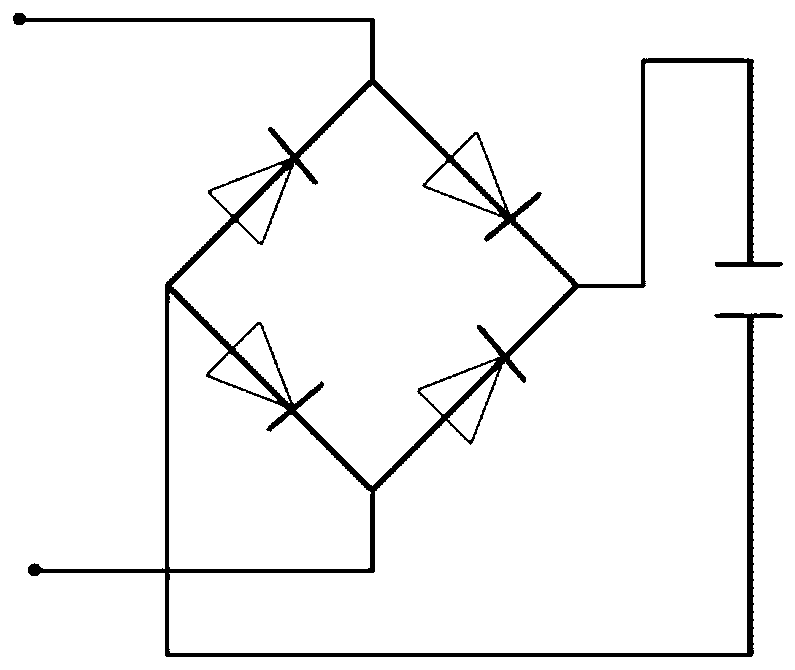

A technology of silencing device and noise energy, applied in circuit devices, battery circuit devices, tube components, etc., to achieve the effects of low economic cost, high reliability, and high-voltage electrical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with the drawings and specific embodiments:

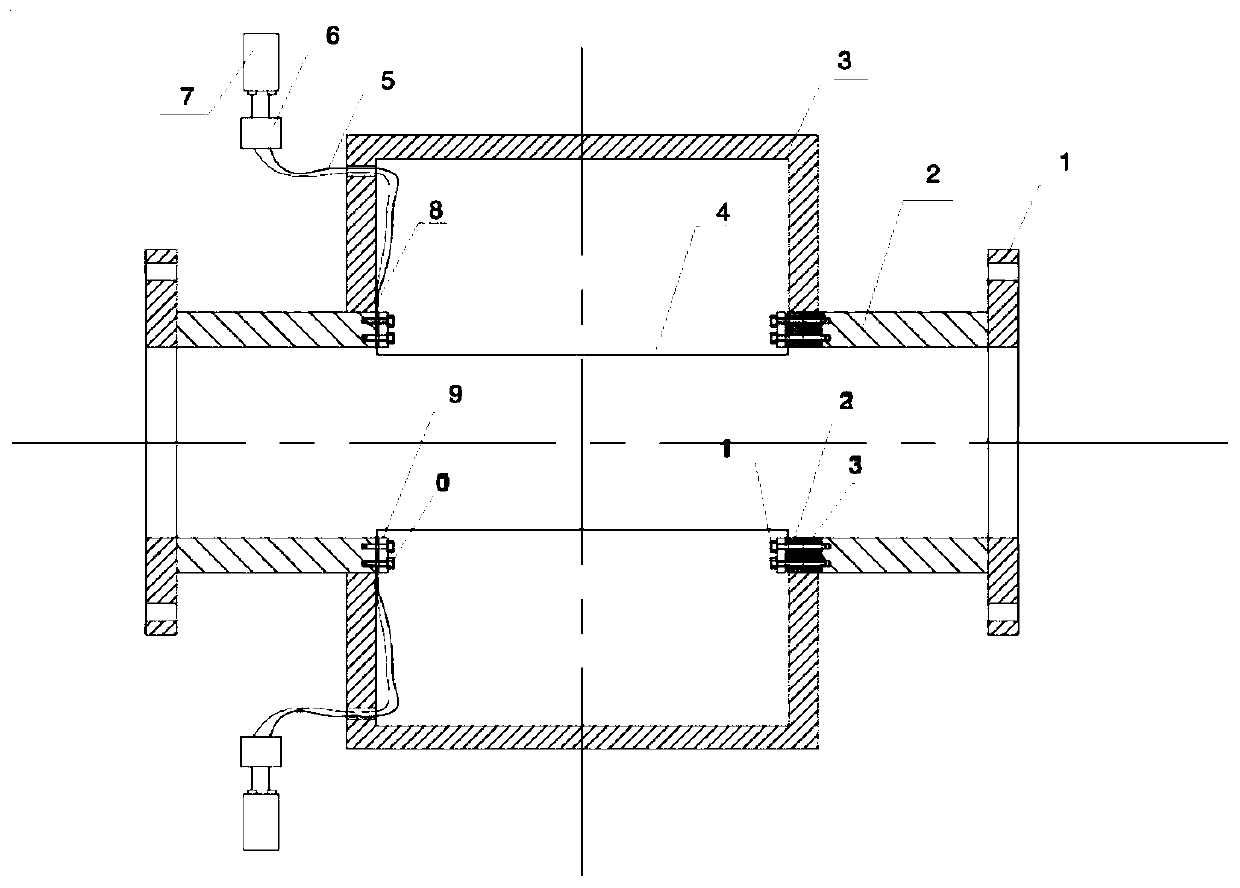

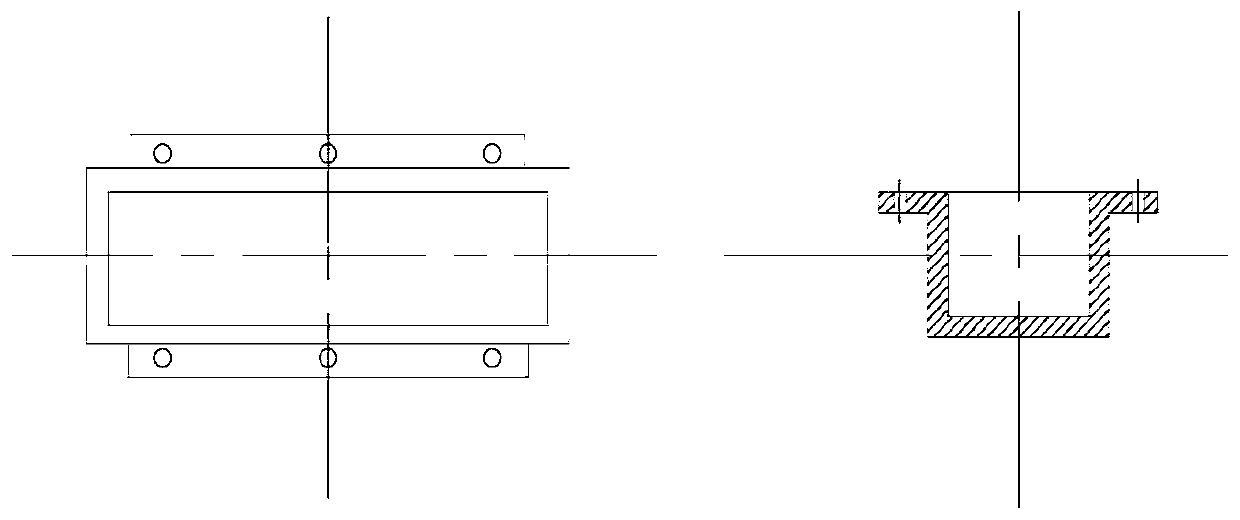

[0024] Such as figure 1 As shown, the present invention is a noise reduction device capable of recovering pipe noise energy, which includes a noise reduction shell and an energy harvesting module. The muffler shell includes the inlet and outlet external pipe flanges 1 bonded at both ends of the connecting pipe 2, and the upper and lower expansion sound chambers 3 connected by bolts. The structure is shown in figure 2 . The energy harvesting module is composed of PVDF piezoelectric film 4, lead interface 8, pressure plate 9, short bolt 10, pre-tensioning device (11-13), rectifier circuit board 6 and energy storage capacitor 7. The left end of the PVDF film 4 is fastened to the left side cutting surface of the connecting pipe by the pressure plate 9, and the right end is pre-tightened by the sliding block 12 and the rubber block 13 through the pre-tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com