3D printing technology based electromechanical equipment training system and construction method thereof

A technology of 3D printers and electromechanical equipment, applied in the field of electromechanical equipment training system and its construction, can solve the problems of complex electromechanical installation and overhaul site conditions, impractical operation, and inability to disassemble and assemble, so as to improve the speed and effect of personnel training, Improve practicality and accuracy, and improve the effect of operation and maintenance management capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

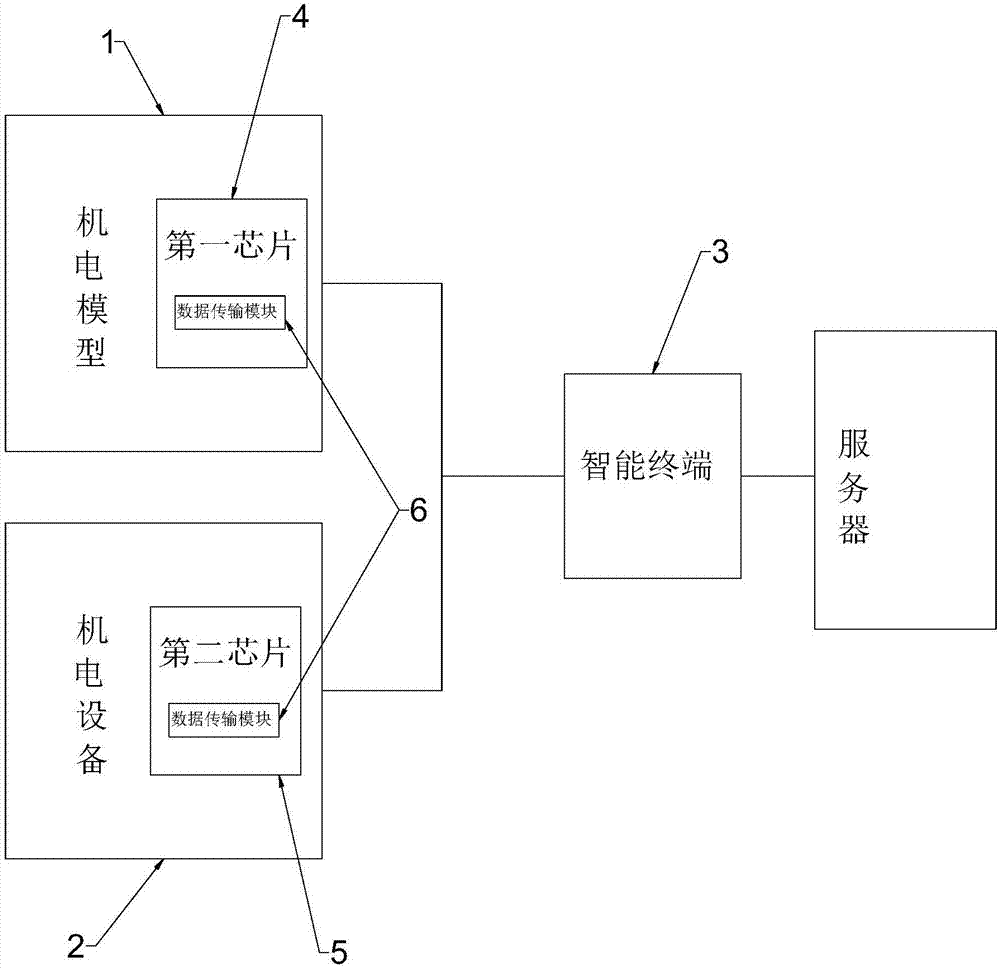

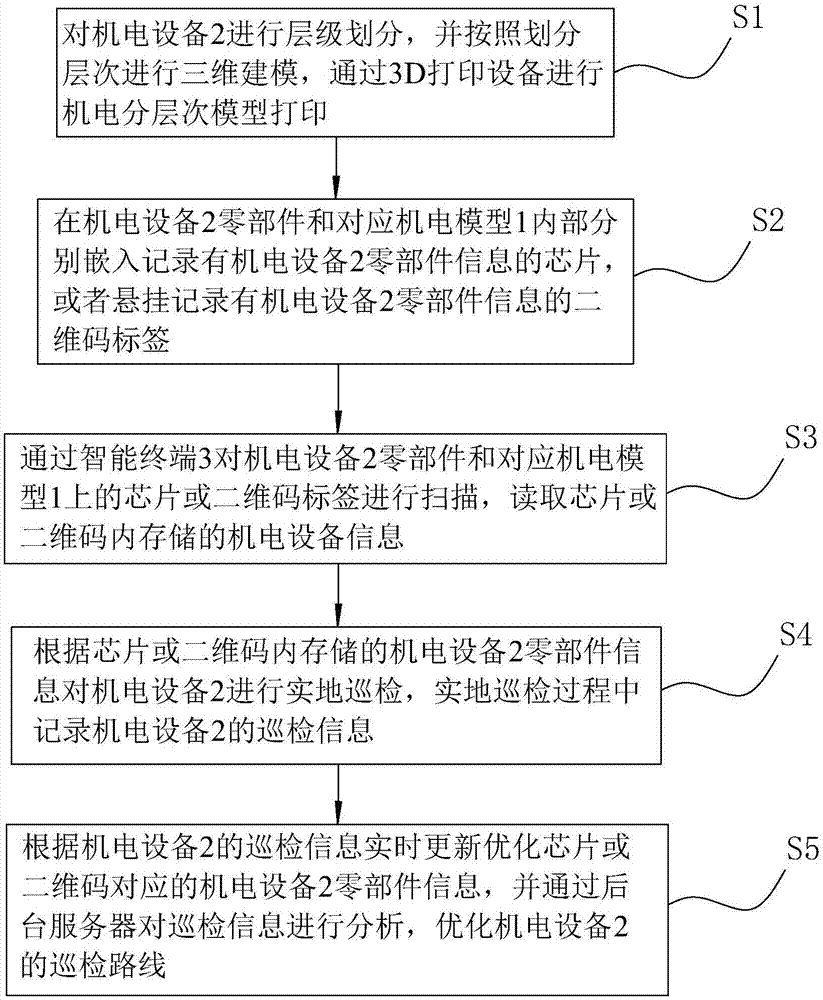

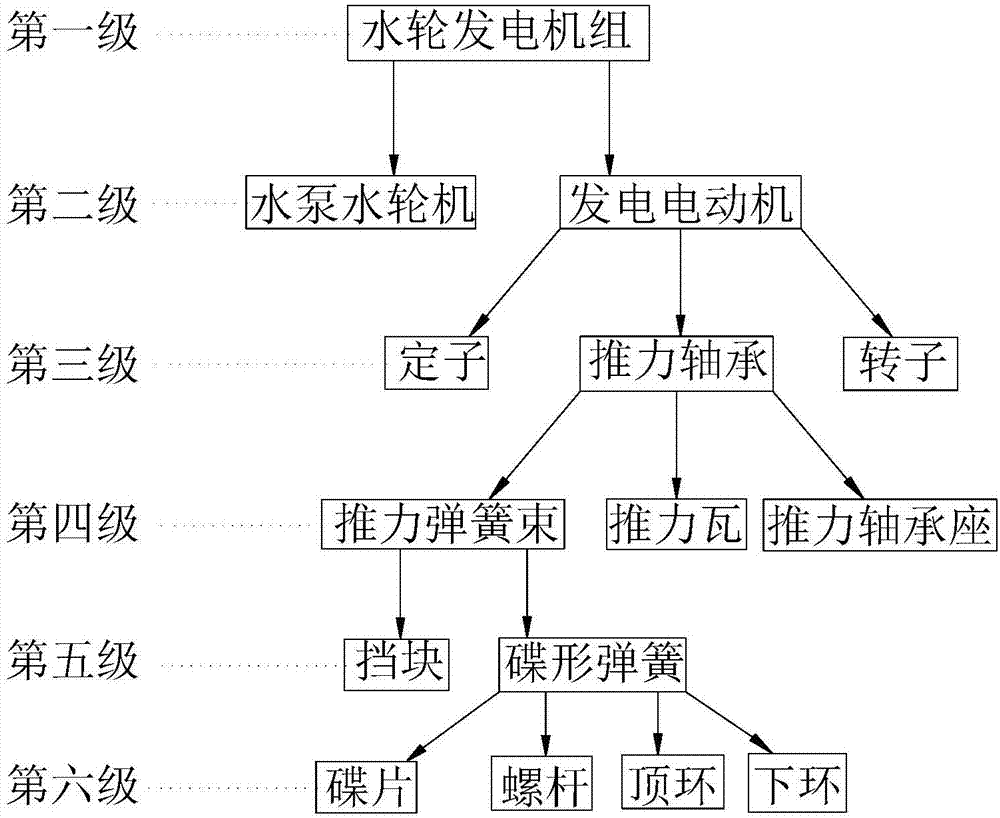

[0041] Such as figure 1As shown, a electromechanical equipment training system based on 3D printing technology, the training system includes electromechanical model 1, electromechanical equipment 2, and intelligent terminal 3; electromechanical model 1 is formed by 3D modeling and printing by a 3D printer based on electromechanical UG, Solidworks, and Pro-e related software can be used for precise 3D modeling, and the dimensions are strictly in accordance with the drawing standards; there is a chip slot on the electromechanical model 1, and the first chip 4 for recording electromechanical equipment information is built in the chip slot, and electromechanical equipment 2 There is a second chip 5 corresponding to the first chip 4; the first chip 4 and the second chip 5 record the same electromechanical equipment information; the intellig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com