A kind of preparation method of copper-rhodium bimetal dendritic material

A bimetallic nano- and dendritic technology, applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of high price and low rhodium storage, and achieve high specific surface area, controllable components, peak and Atom-rich effect at the edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 25mL glass bottle, add 52.8mg of ascorbic acid, 19.7mg of copper acetylacetonate, 10.0mg of rhodium acetylacetonate, 5mL of oleylamine, stir at room temperature for 8 minutes, and then sonicate for 8 minutes. h, and finally cooled down to room temperature naturally, washed with n-hexane several times and stored in n-hexane solution for later use.

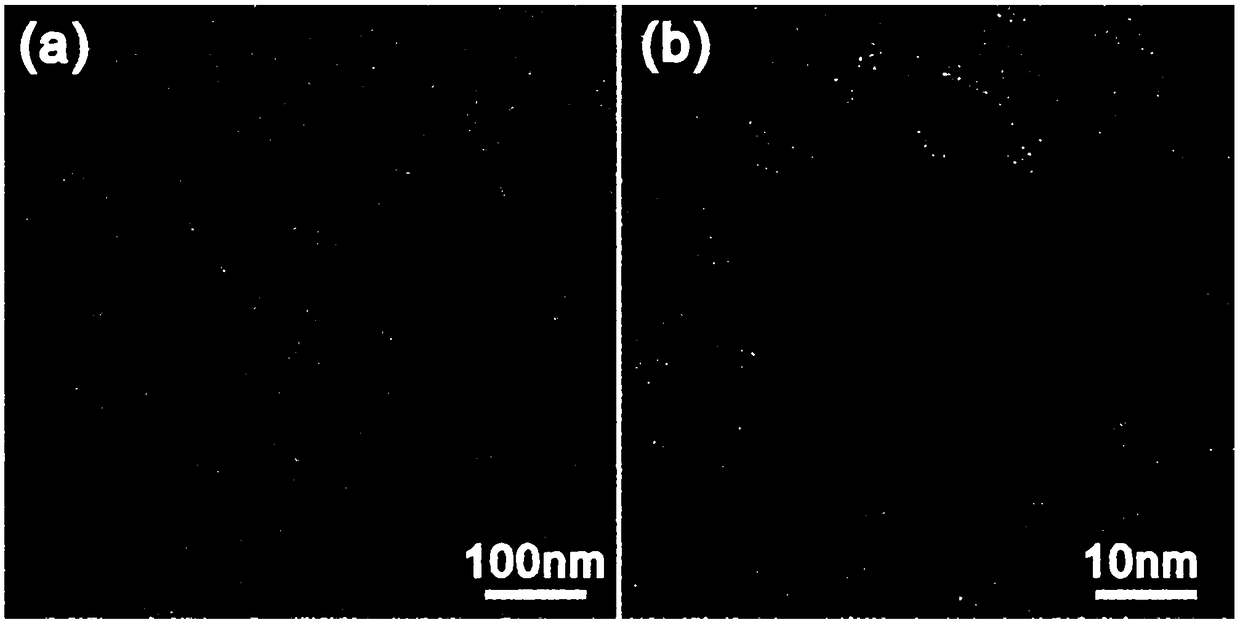

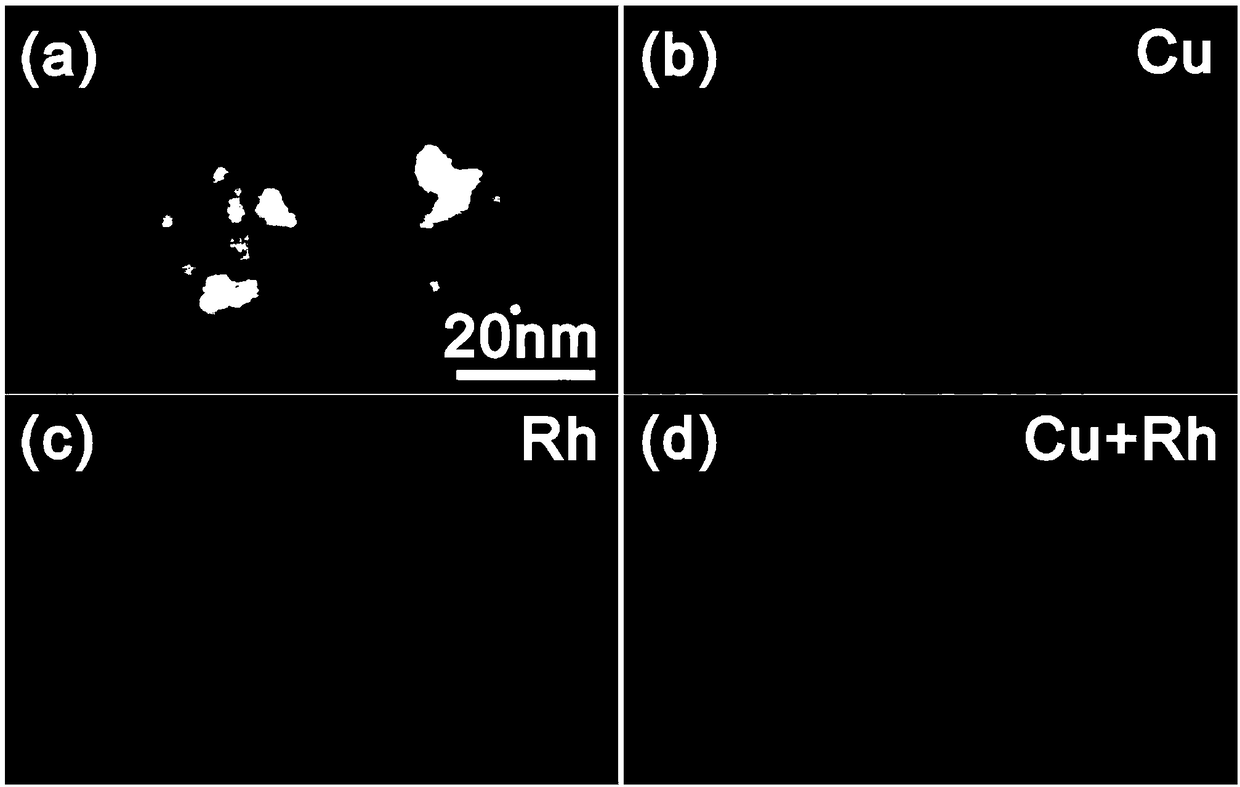

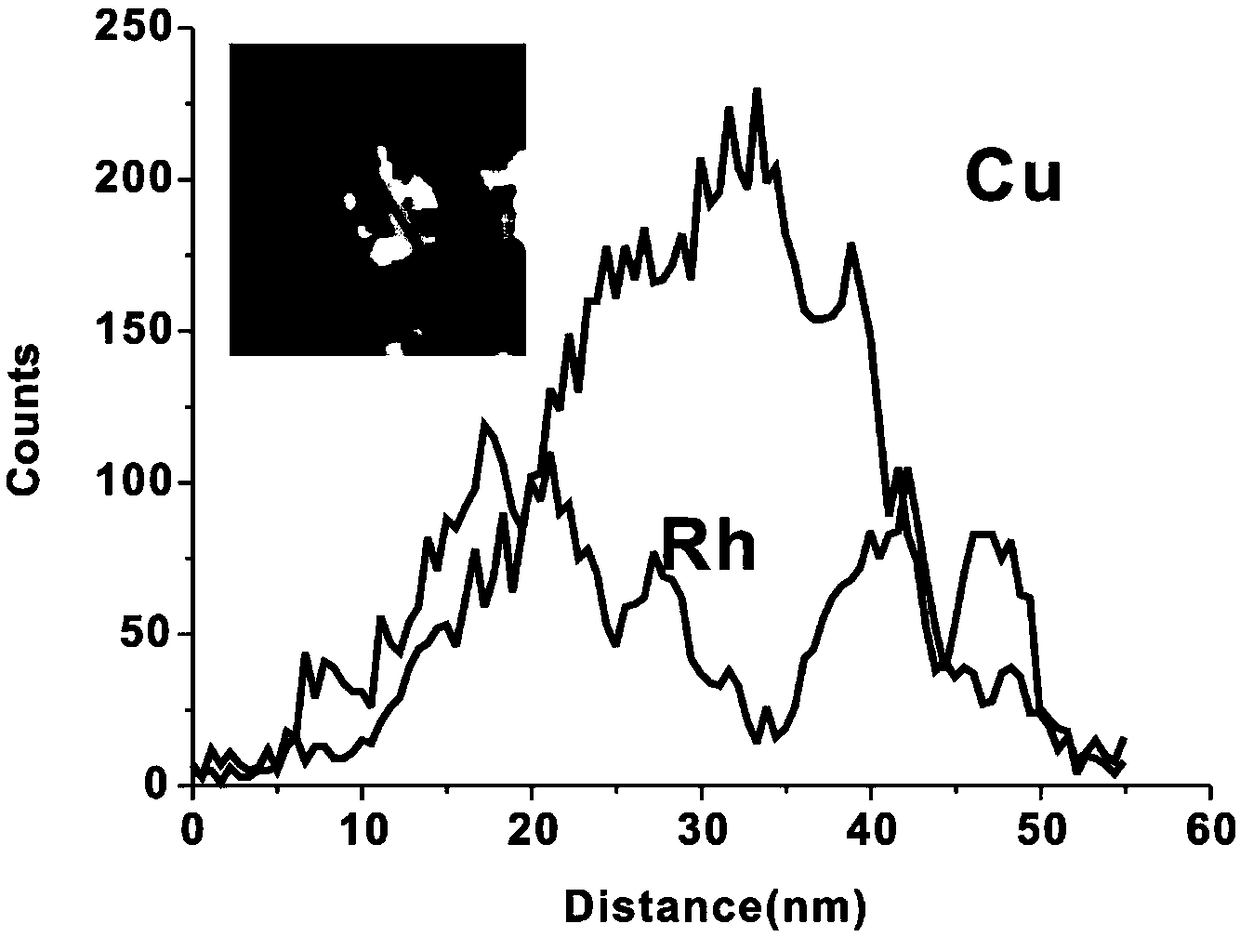

[0025] The morphology, composition and microstructure of the product are systematically studied by TEM, HRTEM, HAADF-STEM, XRD and other modern nano-testing and analysis techniques. TEM, HRTEM ( figure 1 a, b) Characterized as Cu-Rh (3-1) Dendritic nanocrystal structure with a diameter of about 35nm; energy spectrum analysis surface scanning (EDS) ( figure 2 a, b, c, d) and energy spectrum analysis linear scan (EDS) ( image 3 ) to characterize Cu-Rh (3-1) The dendritic nanocrystal is a core-shell structure, the middle copper is the core, and the outer rhodium branch is the heterogeneous structure of the shell.

Embodiment 2

[0027] In a 25mL glass bottle, add 52.8mg of ascorbic acid, 13.3mg of copper acetylacetonate, 20.0mg of rhodium acetylacetonate, and 5mL of oleylamine, stir at room temperature for 8 minutes, and then ultrasonicate for 8 minutes. h, and finally cooled down to room temperature naturally, washed with n-hexane several times and stored in n-hexane solution for later use.

[0028] TEM, HRTEM characterization such as Figure 4 (a, b) is Cu-Rh (1-1) Dendritic nanocrystalline structure with a diameter of about 35nm; the inner copper core becomes smaller, and the outer shell has more rhodium branches.

Embodiment 3

[0030] In a 25mL glass bottle, add 52.8mg of ascorbic acid, 6.7mg of copper acetylacetonate, 30.0mg of rhodium acetylacetonate, 5mL of oleylamine, stir at room temperature for 8 minutes, then ultrasonic for 8 minutes, and put the reaction bottle in an oil bath at 170°C for three hours. , and finally cooled down to room temperature naturally, washed with n-hexane several times and stored in n-hexane solution for later use.

[0031] TEM, HRTEM characterization such as Figure 5 (a, b) is Cu-Rh (1-3) Dendritic nanocrystalline structure with a diameter of about 30nm; the inner copper core is very small, and the outer shell has more rhodium branches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com