Preparation method of graphene paper

A graphene paper, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of no good research results, high energy consumption, difficult separation of materials and filter membranes, etc., to achieve easy separation , uniform thickness, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

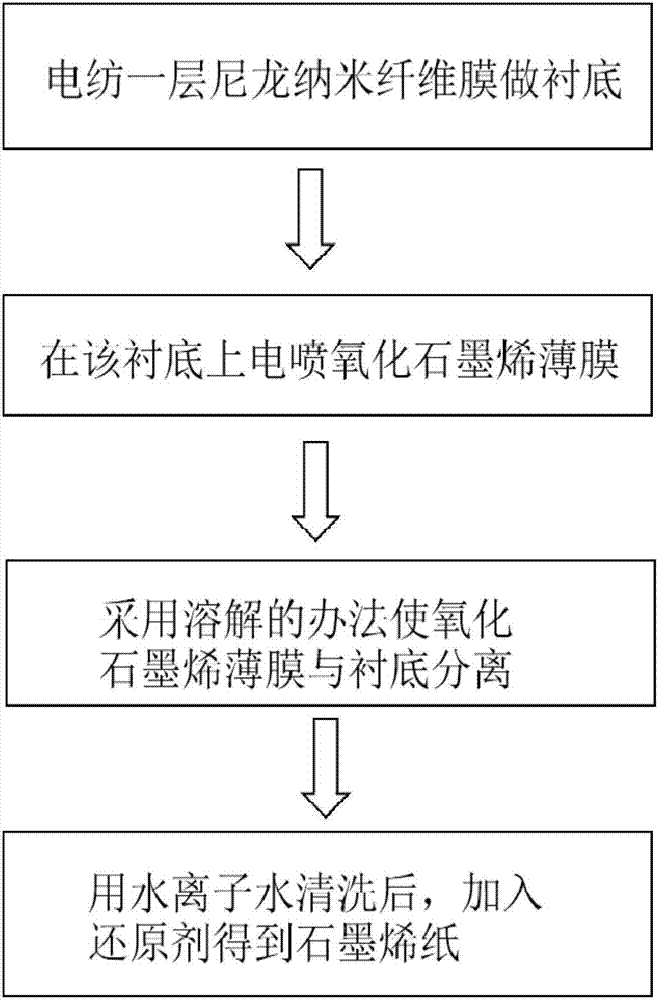

[0034] Such as figure 2 As shown in the flow chart, a method for preparing graphene paper includes the following steps:

[0035] (1) Electrospun nanofiber membrane substrate: Nylon and formic acid are mixed in a mass ratio of 3:22, stirred with a magnetic stirrer for 4 hours to obtain a uniform spinning precursor, and the obtained spinning precursor is added to the electrostatic spinning In the liquid storage mechanism of the device, the aluminum foil is used as the collector, and the nylon nanofiber membrane is prepared by the electrostatic spinning method. The spinning power source is 20kV, the spinning distance is 12-15cm, and the spinning solution is 3ml. The nanofiber membrane lining is obtained on the aluminum foil. bottom;

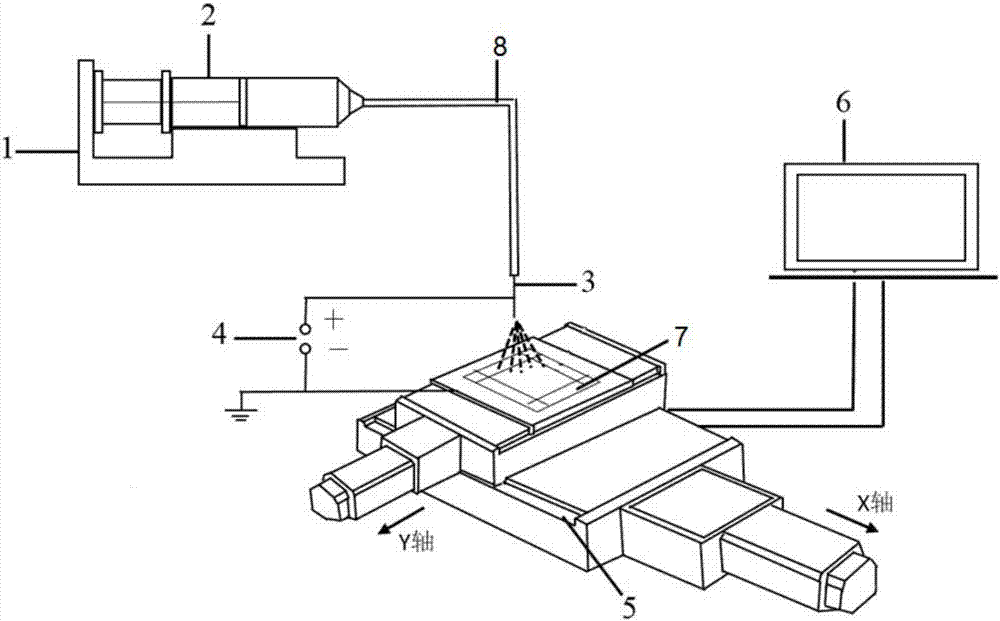

[0036] (2) Electrospray composite graphene oxide film: place the graphene oxide dispersion in figure 1 In the liquid storage mechanism 2 of the electrostatic spray device shown, the aluminum foil attached with the nanofiber film substrate of step (1) is...

Embodiment 2

[0043] A method for preparing graphene paper includes the following steps:

[0044] (1) Electrospun nanofiber membrane substrate: Nylon and formic acid are mixed in a mass ratio of 3:22, stirred with a magnetic stirrer for 4 hours to obtain a uniform spinning precursor, and the obtained spinning precursor is added to the electrostatic spinning In the liquid storage mechanism of the device, a metal plate with a hollow circular pattern is used as a collector, and a nylon nanofiber membrane is prepared by electrospinning. The spinning power source is 20kV, the spinning distance is 15cm, and the spinning solution is 3ml. Obtain a nanofiber membrane substrate on the surface of the metal plate with a circular pattern;

[0045] (2) Electrospray composite graphene oxide film: place the graphene oxide dispersion in figure 1 In the liquid storage mechanism 2 of the electrostatic spray device shown, the metal plate with the hollow circular pattern attached to the nanofiber membrane substrate ...

Embodiment 3

[0049] A method for preparing graphene paper includes the following steps:

[0050] (1) Electrospun nanofiber membrane substrate: Polyvinylpyrrolidone (PVP) is dissolved in deionized water to prepare a solution spinning precursor. The mass fraction of PVP in the spinning precursor is 12%. The silk precursor is added to the liquid storage mechanism of the electrospinning device, the metal plate with a hollow circular pattern is used as the collector, and the nylon nanofiber membrane is prepared by the electrospinning method. The spinning power supply is 20kV, the spinning distance is 15cm, and the spinning Time 20min, that is, the nanofiber membrane substrate is obtained on the surface of the metal plate with the hollow circular pattern;

[0051] (2) Electrospray composite graphene oxide film: place the graphene oxide dispersion in figure 1 In the liquid storage mechanism 2 of the electrostatic spray device shown, the metal plate with the hollow circular pattern attached to the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com