Blend of fluorine-containing elastomers

A technology of elastomers and blends, applied in the field of fluoroelastomer blends, to achieve excellent processability, low modulus, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

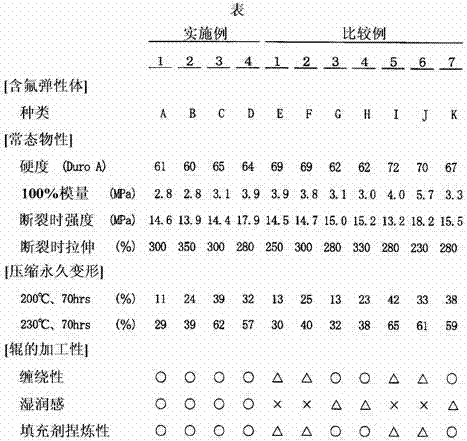

Examples

Embodiment 1

[0057] (1) After substituting and degassing the inside of a stainless steel autoclave with a capacity of 10 L with nitrogen, the following reaction medium was added.

[0058] Surfactant C. 3 f 7 OCF (CF 3 ) CF 2 OCF (CF 3 )COONH 4 8.5g

[0059] Na 2 HPO 4 ・12H 2 O 5.0g

[0060] Ion exchanged water 5000ml

[0061] After the inside of the autoclave was substituted with nitrogen again to degas it, the following reaction raw materials were added.

[0062] Vinylidene fluoride [VdF] 380g (56.0 mol%)

[0063] Hexafluoropropylene [HFP] 700g (44.0mol%)

[0064] Isopropyl alcohol [IPA] 2.0 g (0.065% by weight).

[0065] Next, the temperature in the autoclave was set to 80°C. At this time, it is 32 relative bars (32×10 5 Relative Pa) pressure. Ammonium persulfate [APS] 0.5 g (0.016% by weight) was added thereto as a 0.3% by weight aqueous solution to initiate a polymerization reaction. Keep the pressure at 31-32 relative bar (31-32×10 5 To the state of Pa), the followi...

Embodiment 2

[0081] (1) After substituting and degassing the inside of a stainless steel autoclave with a capacity of 10 L with nitrogen, the following reaction medium was added.

[0082] Surfactant C 3 f 7 OCF (CF 3 ) CF 2 OCF (CF 3 )COONH 4 19.3g

[0083] Na 2 HPO 4 ・12H 2 O 10.0g

[0084] Ion exchanged water 5200ml

[0085] After the inside of the autoclave was substituted with nitrogen again to degas it, the following reaction raw materials were added.

[0086] Vinylidene fluoride [VdF] 101g (34.3 mol%)

[0087] Tetrafluoroethylene [TFE] 49g (10.6 mol%)

[0088] Hexafluoropropylene [HFP] 380g (55.1mol%)

[0089] Isopropyl alcohol [IPA] 2.0 g (0.074% by weight).

[0090] Next, the temperature in the autoclave was set to 80°C. At this time, it is 30 relative bar (30×10 5 Relative Pa) pressure. Ammonium persulfate [APS] 0.8 g (0.030% by weight) was added thereto as a 0.3% by weight aqueous solution to initiate a polymerization reaction. Keep the pressure at 29-30 relati...

Embodiment 3

[0099] (1) After substituting and degassing the inside of a stainless steel autoclave with a capacity of 10 L with nitrogen, the following reaction medium was added.

[0100] Surfactant C 3 f 7 OCF (CF 3 ) CF 2 OCF (CF 3 )COONH 4 19.3g

[0101] Na 2 HPO 4 ・12H 2 O 10.0g

[0102] Ion exchanged water 5200ml

[0103] After the inside of the autoclave was substituted with nitrogen again to degas it, the following reaction raw materials were added.

[0104] Vinylidene fluoride [VdF] 101g (34.3 mol%)

[0105] Tetrafluoroethylene [TFE] 49g (10.6 mol%)

[0106] Hexafluoropropylene [HFP] 380g (55.1mol%)

[0107] 2-Bromo-1,1-difluoroethylene [BDFE] 8.3g

[0108] Octafluoro-1,4-diiodobutane [DIOFB] 3.0 g (0.111% by weight).

[0109] Next, the temperature in the autoclave was set to 80°C. At this time, it is 30 relative bar (30×10 5 Relative Pa) pressure. 1.0 g (0.037% by weight) of ammonium persulfate [APS] was added thereto as a 0.3% by weight aqueous solution to init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com