Method for preparing arrayed TiO2 by catalytic oxidizing of pure Ti sodium tetraborate

A catalytic oxidation, sodium tetraborate technology, applied in nanotechnology for materials and surface science, metal material coating process, nanotechnology, etc., can solve the problems of expensive thin film area, restricted, etc. Ease of handling, increased surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

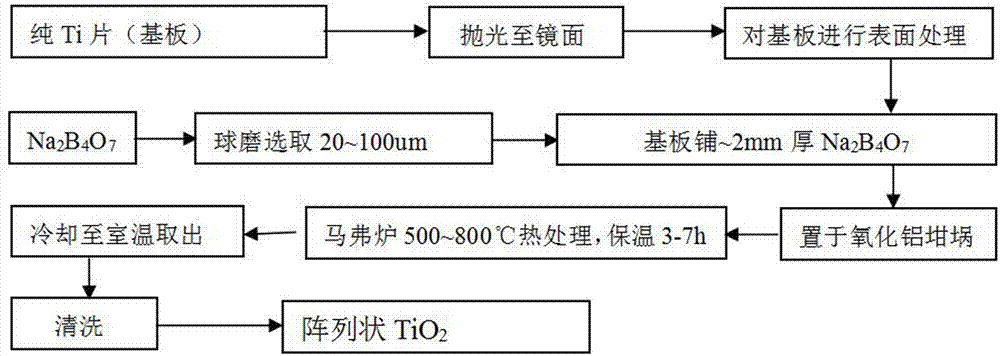

[0023] Catalytic Oxidation of Pure Ti with Sodium Tetraborate to Prepare Array-like TiO 2 Methods:

[0024] (1) Surface pretreatment of pure Ti substrate (pure titanium sheet)

[0025] The titanium rod with a purity of 99.99% is taken, and it is cut into samples of the required size (10x20x1mm) by a wire cutting machine. After being polished with No400, No600, No800, and No1000 sandpaper in sequence, electrolytic polishing is performed. Put the sample in acetone solution and ultrasonically clean it for 10-20 minutes to remove surface oil and wear debris, then rinse it with distilled water, put it in acetone solution and wipe it with absorbent cotton for later use;

[0026] (2) Anhydrous sodium tetraborate with a purity of 99.5% was screened out to 20um with a sampling sieve, put into a sample belt, marked, and stored in a dry place.

[0027] (3) Preparation of TiO by catalytic oxidation of sodium tetraborate 2

[0028] The anhydrous sodium tetraborate fine powder screened ...

Embodiment 2

[0030] Catalytic Oxidation of Pure Ti with Sodium Tetraborate to Prepare Array-like TiO 2 Methods:

[0031] (1) Surface pretreatment of pure Ti substrate (pure titanium sheet)

[0032] The titanium rod with a purity of 99.99% is taken, and it is cut into samples of the required size (10x20x1mm) by a wire cutting machine. After being polished with No400, No600, No800, and No1000 sandpaper in sequence, electrolytic polishing is performed. Put the sample in acetone solution and ultrasonically clean it for 10-20 minutes to remove surface oil and wear debris, then rinse it with distilled water, put it in acetone solution and wipe it with absorbent cotton for later use;

[0033] (2) Screen anhydrous sodium tetraborate with a purity of 99.5% to 20~100um with a sampling sieve, put it into a sample belt, mark it well, and store it dry.

[0034] (3) Preparation of TiO by catalytic oxidation of sodium tetraborate 2

[0035] The anhydrous sodium tetraborate fine powder screened in (2)...

Embodiment 3

[0037] Catalytic Oxidation of Pure Ti with Sodium Tetraborate to Prepare Array-like TiO 2 Methods:

[0038] (1) Surface pretreatment of pure Ti substrate (pure titanium sheet)

[0039] The titanium rod with a purity of 99.99% is taken, and it is cut into samples of the required size (10x20x1mm) by a wire cutting machine. After being polished with No400, No600, No800, and No1000 sandpaper in sequence, electrolytic polishing is performed. Put the sample in acetone solution and ultrasonically clean it for 10-20 minutes to remove surface oil and wear debris, then rinse it with distilled water, put it in acetone solution and wipe it with absorbent cotton for later use;

[0040] (2) Screen anhydrous sodium tetraborate with a purity of 99.5% to 20~100um with a sampling sieve, put it into a sample belt, mark it well, and store it dry.

[0041] (3) Preparation of TiO by catalytic oxidation of sodium tetraborate 2

[0042] The anhydrous sodium tetraborate fine powder screened in (2) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com