Equivalent stiffness-based dynamic SSS clutch modeling method

A technology of dynamic modeling and equivalent stiffness, applied in instruments, special data processing applications, electrical and digital data processing, etc., can solve the problems of shafting vibration analysis difficulties, equipment damage, and obstacles to the production of units, and can solve the problems of shafting vibration analysis. Vibration calculation slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

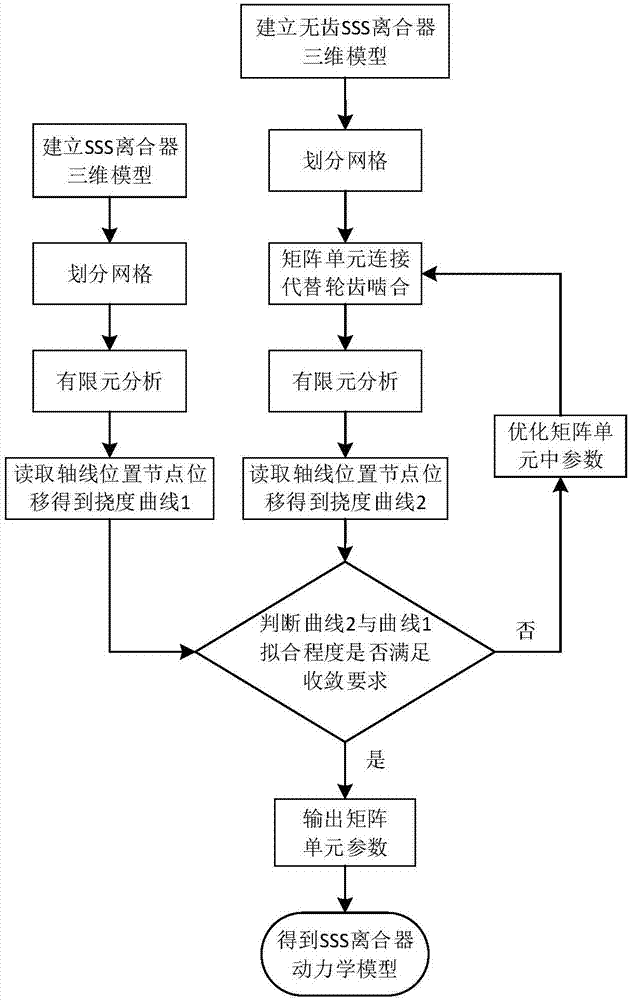

[0067] 1) see figure 1 , the present invention aims to establish a SSS clutch dynamics modeling method based on the equivalent stiffness method, which lays the foundation for the shafting vibration analysis of the combined cycle unit with the SSS clutch. Based on this purpose, a method based on the equivalent stiffness method is designed Overall flowchart of the SSS clutch dynamics modeling method.

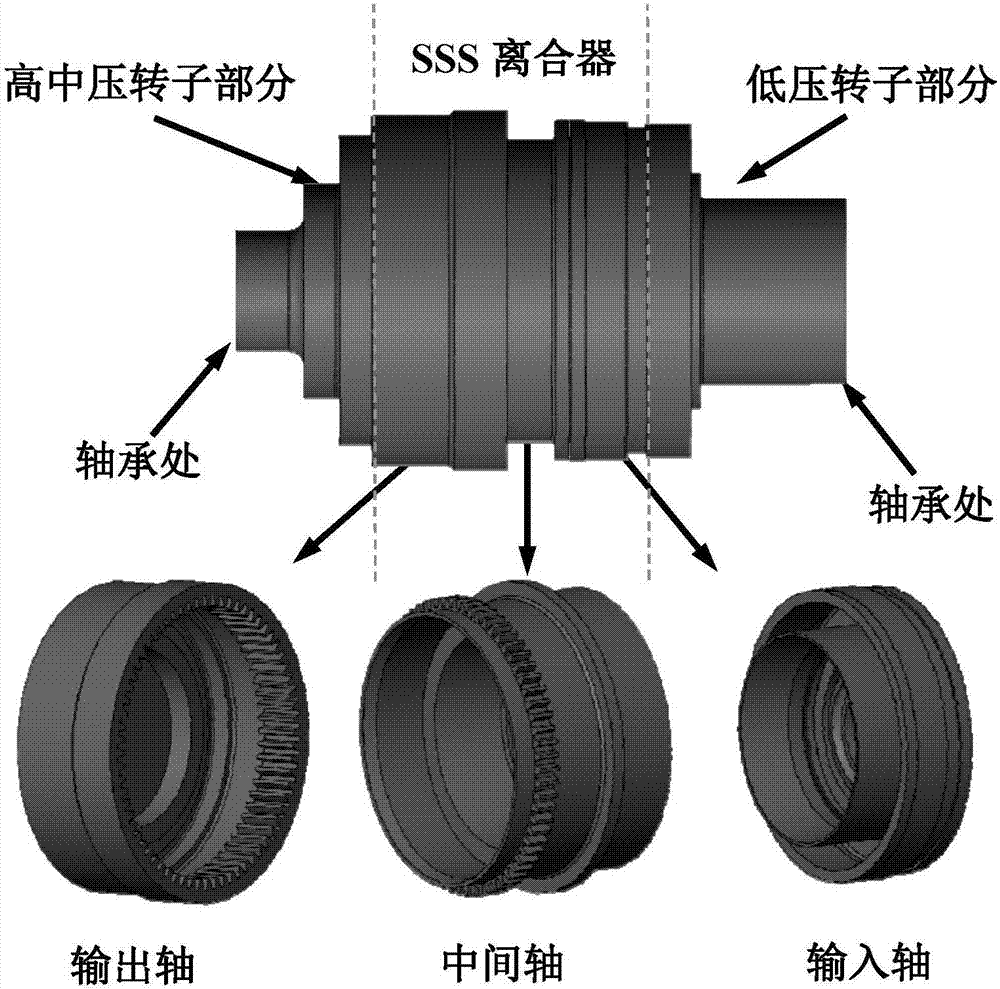

[0068] 2) see figure 2 , this embodiment considers the influence of the bearings at both ends of the SSS clutch, and the research model is the shaft section between the bearings 7 and 8 at both ends of the SSS clutch, including: input shaft 1, intermediate shaft 2, output shaft 3, high and medium pressure rotor 4 , Low pressure rotor 5, bearing 6 and bearing 7. First, the SSS clutch is introduced. The SSS clutch consists of input shaft 1, int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com