Preparation method of vacuum low-temperature fried beancurd puff

A technology of vacuum low-temperature frying and tofu soaking, which is applied in the field of soybean product processing, can solve the problems of high oil content, loss of nutrients, easy burnt and other problems, and achieve the effect of safe operation, pure taste and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

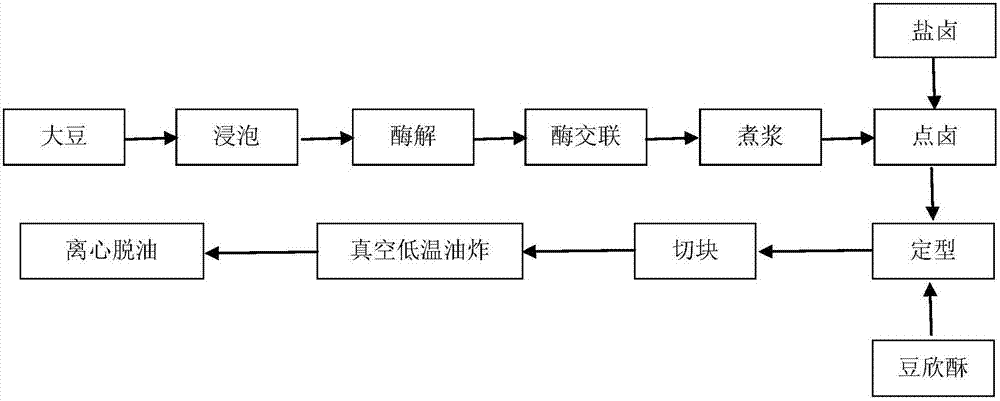

Method used

Image

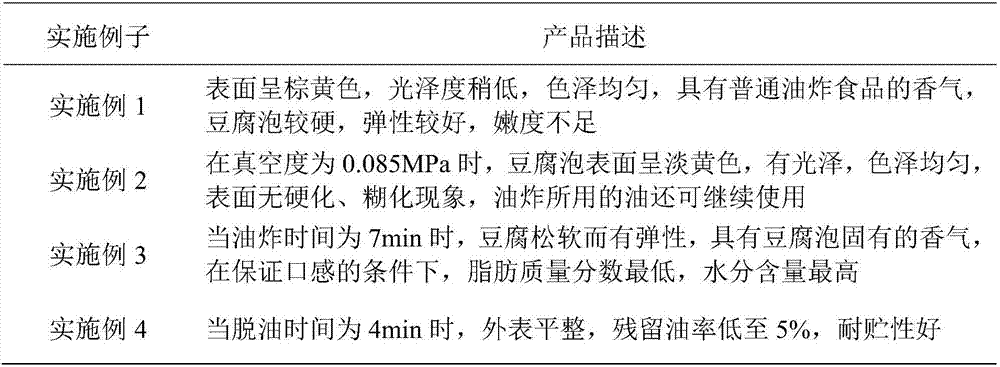

Examples

Embodiment 1

[0016] How to make traditional fried tofu puffs:

[0017] 1) After cleaning the soybeans, add weak alkaline water at a volume ratio of 1:5 to soak for 8 hours, then add 4 times the volume of pure water with a temperature of 50-55°C to grind into a slurry, and centrifuge to remove the residue components;

[0018] 2) After boiling the pulp to 97-100°C, add bittern (CaCl 2 ) for pointing treatment; 3) standing in the forming box for 10 to 13 minutes, and repeating three times for 10 minutes of extrusion and draining forming treatment;

[0019] Cut the solidified tofu into small squares of 5cm to 7cm, and put the cut tofu into the oil at a temperature of about 120°C to make it expand, deform and bulge. Then heat up to 180°C and deep-fry thoroughly, remove and let stand to control oil and cool.

Embodiment 2

[0021] 1) After cleaning the soybeans, add weak alkaline water at a volume ratio of 1:5 to soak for 8 hours, then add 4 times the volume of pure water with a temperature of 50-55°C to grind into a slurry, adjust the pH of the slurry to 9.2 with NaOH solution, and add to the mixed solution Add protex-6L alkaline protease with a slurry mass of 1.0 to 2.5% (w / w) to carry out enzymatic hydrolysis for 30 to 40 minutes to obtain enzymatic soybean milk, and centrifuge to remove the residue components; 2) adjust the pH of the enzymatic soybean milk to 6.5, add Slurry quality 0.10±0.15% (w / w) Glutamine transaminase was reacted at a constant temperature of 35°C for 1.0-1.5h, then boiled to kill the enzyme, and then the mass concentration was added to 2.0±0.2% bittern (CaCl 2 ) for point slurry treatment;

[0022] 3) After dispensing, add Douxin Crisp with a slurry mass of 0.9±0.2% (w / w), and let it rest for 10 to 13 minutes to allow the protein to coagulate fully. Repeat three times in...

Embodiment 3

[0026] 1) After cleaning the soybeans, add weak alkaline water at a volume ratio of 1:5 to soak for 8 hours, then add 4 times the volume of pure water at a temperature of 50-55°C to grind into a slurry, adjust the pH of the slurry to 9.2 with NaOH solution, and add to the mixed solution Add protex-6L alkaline protease with a slurry mass of 1.0 to 2.5% (w / w) to carry out enzymatic hydrolysis for 30 to 40 minutes to obtain enzymatic soybean milk, and centrifuge to remove the residue components; 2) adjust the pH of the enzymatic soybean milk to 6.5, add Slurry quality 0.10±0.15% (w / w) Glutamine transaminase was reacted at a constant temperature of 35°C for 1.0-1.5h, then boiled to kill the enzyme, and the temperature was naturally lowered to 80-85°C, then added with a mass concentration of 2.0±0.2% bittern (CaCl 2 ) for point slurry treatment;

[0027] 3) After dispensing, add Douxin Crisp with a slurry mass of 0.9±0.2% (w / w), and let it rest for 10 to 13 minutes to allow the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com