Small-sized pickling sludge filter press

A technology of sludge filter press and small acid, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., which can solve the problem of increasing manpower, time and equipment, and unable to press filter The state adjustment of the pickling sludge and the low efficiency of pickling sludge treatment can achieve the effects of easy cleaning and maintenance, high safety factor and saving treatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

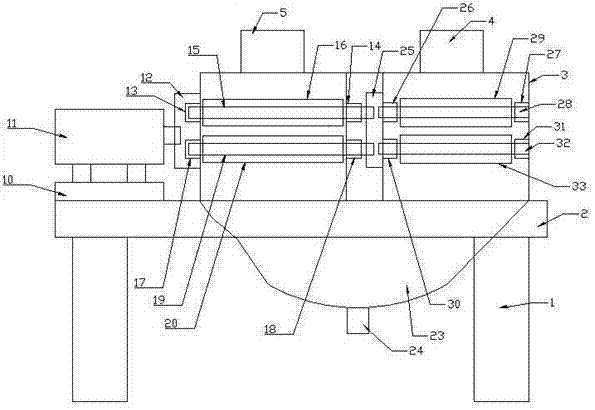

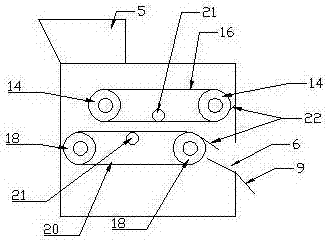

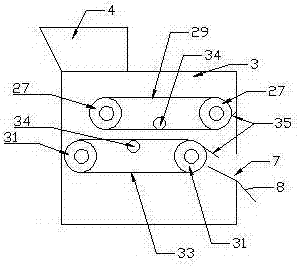

[0016] Such as figure 1 , figure 2 and image 3 A small pickling sludge filter press shown consists of a leg 1, an installation frame bottom plate 2 arranged on the outrigger 1, a filter press box 3 arranged on the installation frame bottom plate 2, and a filter press box arranged on the filter press The first feed port 4 on the box 3, the second feed port 5, and the liquid collection tank 23 that is arranged on the bottom of the filter press box 3, and the liquid outlet 24 that is arranged on the liquid collection tank 23, and is arranged on the installation The motor mounting plate 10 on the frame bottom plate 2, the driving motor 11 arranged on the motor mounting plate 10, the first filter press assembly used in conjunction with the drive motor 11, and the first filter press assembly used in conjunction with the first filter press assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com