Piezoresistive compound sensor suitable for surface mounting technology and manufacturing method thereof

A composite sensor and pressure sensor technology, applied in the field of sensors, can solve problems affecting device performance, increasing the difficulty and cost of device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

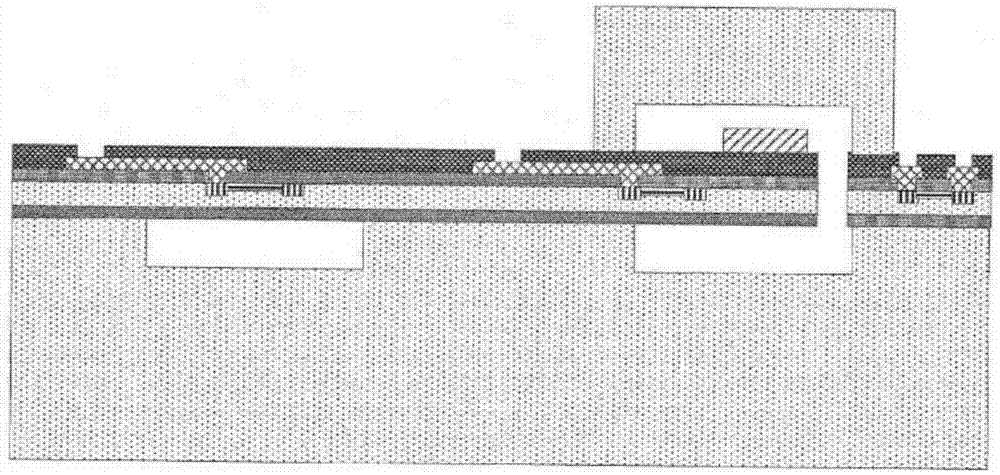

[0171] The embodiment of the present invention is based on a silicon (Cayity-SOI) wafer on an insulating substrate with a pre-set cavity. In the first and second embodiments, the wafer structure is as follows Figure 7 shown. The wafer includes a substrate silicon 200 , an insulating layer 300 (silicon dioxide), a first pre-cavity 400 , a second pre-cavity 500 , and a top layer of silicon 600 . The doping concentration and crystal orientation of the top-layer silicon 600 and the substrate silicon 200 can be freely selected according to actual needs, but the doping methods of the top-layer silicon 600 and the substrate silicon 200 must be opposite. Only one typical application is listed here: both the top silicon 600 and the substrate silicon 200 adopt (100) crystal orientation, the top silicon 600 is N-type doped, and the substrate silicon 200 is P-type doped (of course, the top silicon 600 is P-type doping, and substrate silicon 200 is N-type doping). The position, depth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com