Grouting material and preparation method thereof

A technology of grouting materials and raw materials, which is applied in the field of building materials, can solve the problems of low 3D compressive strength and low compressive strength, and achieve the effects of protecting the environment, broad application prospects, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

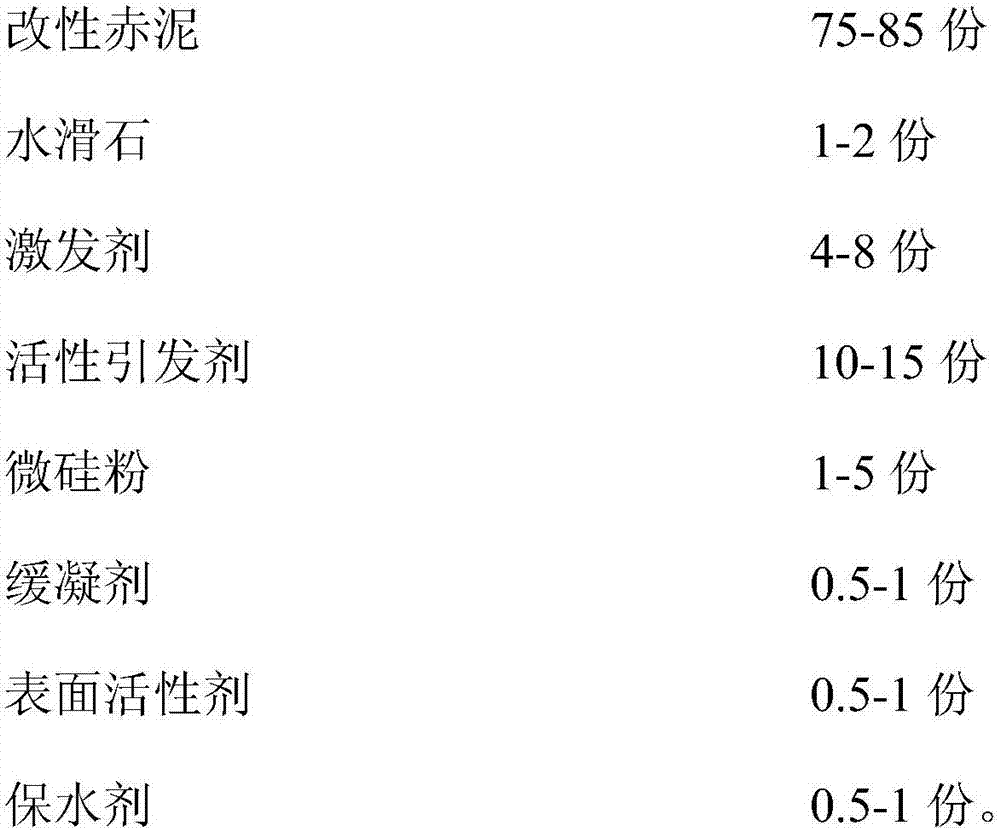

[0036] A grouting material, the raw material components of the grouting material include in parts by weight:

[0037]

[0038] Wherein, the modified red mud is prepared by the following method: calcining the red mud at 450° C. for 4 hours, dispersing the calcined product in Na 2 WO 4 , NaOH and hydantoin derivatives in aqueous solution (Na 2 WO 4 , NaOH and hydantoin derivatives in a molar ratio of 1:10:3), and reacted at 70°C for 8h to obtain modified red mud.

Embodiment 2

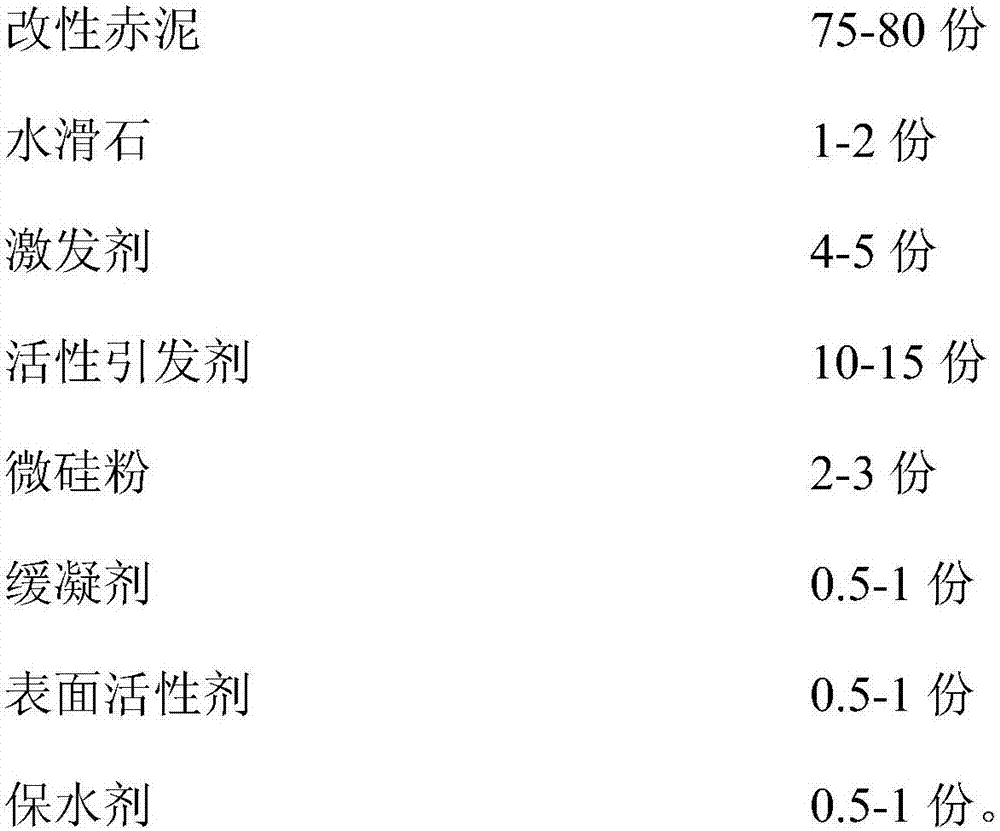

[0040] A grouting material, the raw material components of the grouting material include in parts by weight:

[0041]

[0042] Wherein, the modified red mud is prepared by the following method: calcining the red mud at 600° C. for 1 h, dispersing the calcined product in Na 2 WO 4 , NaOH and hydantoin derivatives in aqueous solution (Na 2 WO 4 , NaOH and hydantoin derivatives in a molar ratio of 1:1:5), and reacted at 80° C. for 5 hours to obtain modified red mud.

Embodiment 3

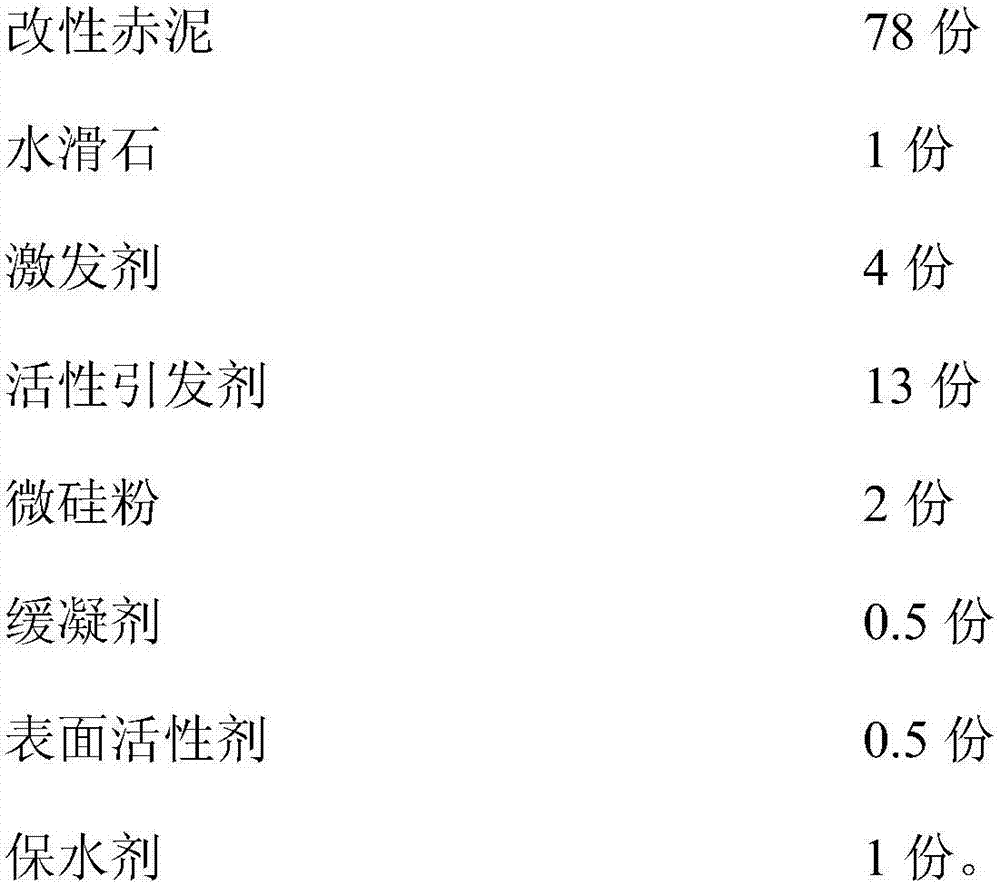

[0044] A grouting material, the raw material components of the grouting material include in parts by weight:

[0045]

[0046]

[0047] Wherein, the modified red mud is prepared by the following method: calcining the red mud at 500°C for 2 hours, dispersing the calcined product in Na 2 WO 4 , NaOH and hydantoin derivatives in aqueous solution (Na 2 WO 4 , NaOH and hydantoin derivatives in a molar ratio of 1:10:5), and reacted at 75°C for 6h to obtain modified red mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com