Binder, and preparation method thereof

A binder and modifying agent technology, applied in the field of binder and its preparation, can solve the problems of compact impermeability and poor rolling crack resistance, achieve good impermeability and crack resistance, short steps, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

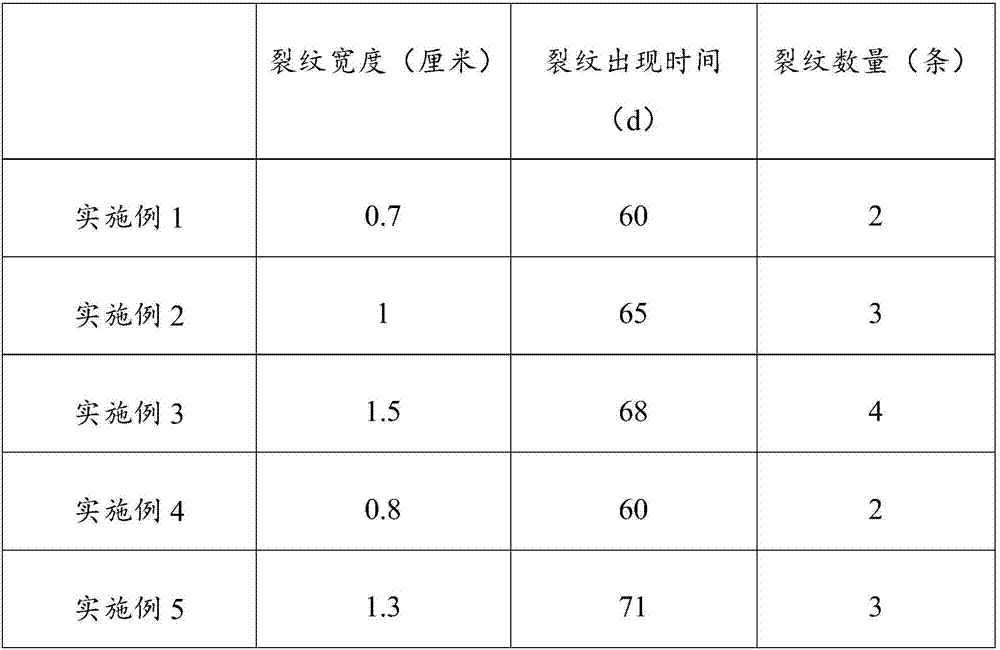

Examples

preparation example Construction

[0030] It should be noted that there is no particular order for the preparation of the modifier, the preparation of magnesium oxide, and the preparation of the magnesium chloride solution, and one substance can be prepared first at will, or can be prepared at the same time.

[0031] S2, preparing binder;

[0032] Mix the magnesium chloride solution, magnesium oxide, modifier and sawdust according to the mass ratio of 1:0.7-1.1:3-5:15-21 and stir evenly, and use the bonding agent within 0.5-6 hours after mixing agent. The magnesium chloride solution, the magnesium oxide, the modifier and the sawdust adopt the above-mentioned proportions to ensure a fast-forming adhesive with excellent adhesive performance. After research by the inventor, it is found that the adhesive must be used within 0.5-6 hours after the preparation of the adhesive, otherwise the structure of the adhesive will change, which will cause the adhesive to lose its bonding function and crack resistance and impe...

Embodiment 1

[0038] This embodiment provides a binder, which is mainly made of 1g magnesium chloride solution, 0.8g magnesium oxide, 2g modifier and 1.5g wood chips. Among them, the magnesium chloride solution includes 0.23g magnesium chloride and 0.77g water; the sawdust is the wood surface; the magnesium oxide includes 0.24g active magnesium oxide and 0.56g lightly burned magnesium oxide; the modifier mainly consists of 0.7g acid solution, 0.3g polyethylene Diol, 0.3g formaldehyde and 0.7g catechol; its acid solution is dilute hydrochloric acid with a mass percentage of 0.5%.

[0039] Present embodiment also provides a kind of method for preparing adhesive:

[0040] S1, prepare magnesium chloride solution, magnesium oxide and modifier respectively;

[0041] Add 0.23 g of magnesium chloride to 0.77 g of water and stir until the magnesium chloride is completely dissolved, thereby obtaining a magnesium chloride solution.

[0042] The magnesia was prepared by mixing 0.24g of active magnesi...

Embodiment 2

[0047] This embodiment provides a binder, which is mainly made of 1g of magnesium chloride solution, 1g of magnesium oxide, 2.5g of modifier and 3g of sawdust. Among them, the magnesium chloride solution includes 0.33g magnesium chloride and 0.67g water; the sawdust is plant straw powder; the magnesium oxide includes 0.15g active magnesium oxide and 0.85g lightly burned magnesium oxide; the modifier mainly consists of 0.51g acid solution, 0.41g polyethylene Diol, 0.21g formaldehyde, 0.61g catechol and 0.76 triethanolamine; its acid solution is dilute hydrochloric acid with a mass percentage of 1.5%.

[0048] Present embodiment also provides a kind of method for preparing adhesive:

[0049] S1, prepare magnesium chloride solution, magnesium oxide and modifier respectively;

[0050] Add 0.33 g of magnesium chloride to 0.67 g of water and stir until the magnesium chloride is completely dissolved, thereby obtaining a magnesium chloride solution.

[0051] The magnesia was prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com