Technology of preparing mangiferin by using mangifera indica leaves

A technology of mango leaves and mangiferin, which is applied in the field of mangiferin preparation, can solve the problems of reducing product safety, failing to meet the requirements of qualitative and quantitative reference substances, low purity of mangiferin, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

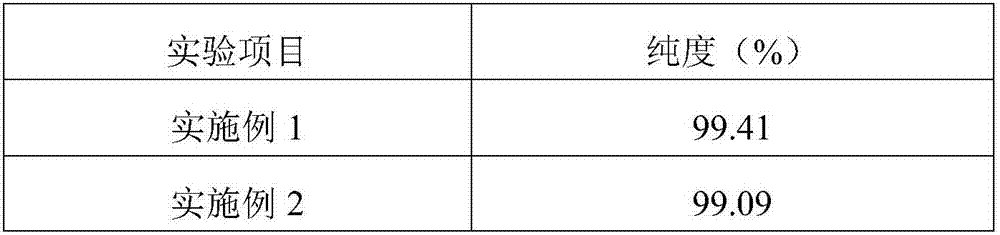

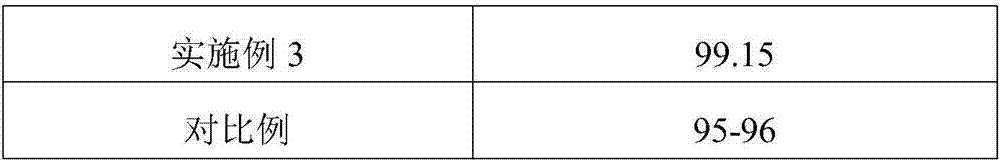

Examples

Embodiment 1

[0037] A kind of technology that adopts mango leaf to prepare mangiferin, comprises the following steps:

[0038] S1: drying the mango leaves to a moisture content of 3%, crushing and passing through a 70-mesh sieve to obtain mango leaf powder;

[0039] S2: Add 80% ethanol and 1-allyl-3-methylimidazole chloride in a mass ratio of 10:1 to the mango leaf powder prepared in step S1, wherein the mango leaf powder is mixed with ethanol and 1-propyl- The total weight ratio of 3-methylimidazole acetate is 1:6, reflux extraction under water bath conditions twice, each extraction time is 2.2h, after the extraction is complete, combine the extracts, adjust the pH value of the extracts to 5, Control the temperature at 72°C, decolorize and remove impurities by activated carbon for 0.8h, and obtain a decolorizing solution after filtration;

[0040] S3: Concentrate and dry the primary decolorization solution obtained in step S2 to obtain an extract extract, which is dissolved in water at 4...

Embodiment 2

[0046] A kind of technology that adopts mango leaf to prepare mangiferin, comprises the following steps:

[0047] S1: drying the mango leaves to a moisture content of 2.5%, crushing and passing through a 50-mesh sieve to obtain mango leaf powder;

[0048] S2: Adding 75% ethanol and 1-allyl-3-methylimidazole chloride with a mass ratio of 8:1 to the mango leaf powder prepared in step S1, wherein the mango leaf powder is mixed with ethanol and 1-propyl- The total weight ratio of 3-methylimidazole acetate is 1:4, reflux extraction under water bath conditions twice, each extraction time is 2.4h, after the extraction is complete, combine the extracts, adjust the pH value of the extracts to 4.8, Control the temperature at 70°C, decolorize and remove impurities by activated carbon for 1 hour, and obtain a decolorizing solution after filtration;

[0049] S3: Concentrate and dry the primary decolorization solution obtained in step S2 to obtain an extract extract, which is dissolved in wa...

Embodiment 3

[0055] A kind of technology that adopts mango leaf to prepare mangiferin, comprises the following steps:

[0056] S1: drying the mango leaves to a moisture content of 2.2%, crushing and passing through an 80-mesh sieve to obtain mango leaf powder;

[0057] S2: Adding 85% ethanol and 1-allyl-3-methylimidazole chloride with a mass ratio of 12:1 to the mango leaf powder prepared in step S1, wherein the mango leaf powder is mixed with ethanol and 1-propyl- The total weight ratio of 3-methylimidazole acetate is 1:8, reflux extraction 3 times under water bath conditions, each extraction time is 1.8h, after the extraction is complete, combine the extracts, adjust the pH value of the extracts to 5.1, Control the temperature at 75°C, decolorize and remove impurities by activated carbon for 0.5h, and obtain a decolorizing solution after filtration;

[0058] S3: Concentrate and dry the primary decolorization solution obtained in step S2 to obtain an extract extract, which is dissolved i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com