High-strength anti-fatigue in-situ nano strengthening aluminum alloy and die casting method thereof

An anti-fatigue, aluminum alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of strong plasticity, low anti-fatigue performance, can not meet the high strength, anti-fatigue, high damping of high-performance engine parts, etc. Guarantee the effect of die-casting performance, good die-casting performance, high-strength anti-fatigue damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using Al-10Zr, Al-10B, Al-20Er, Al-20Fe, Al-10Mn master alloys and pure Ni, pure Mg, pure Zn, and AlSi9Cu3 as raw materials, the optimized nonlinear high pressure die-casting technology is used to prepare automobile engine reduction Tremor bracket.

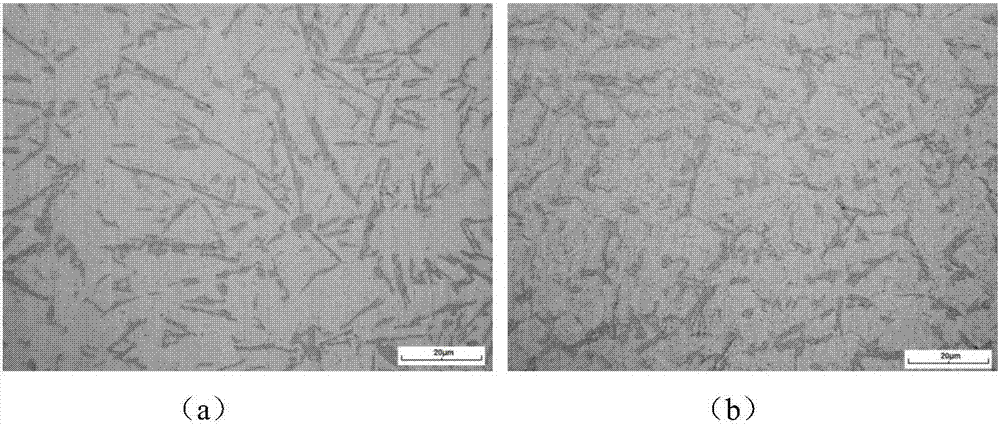

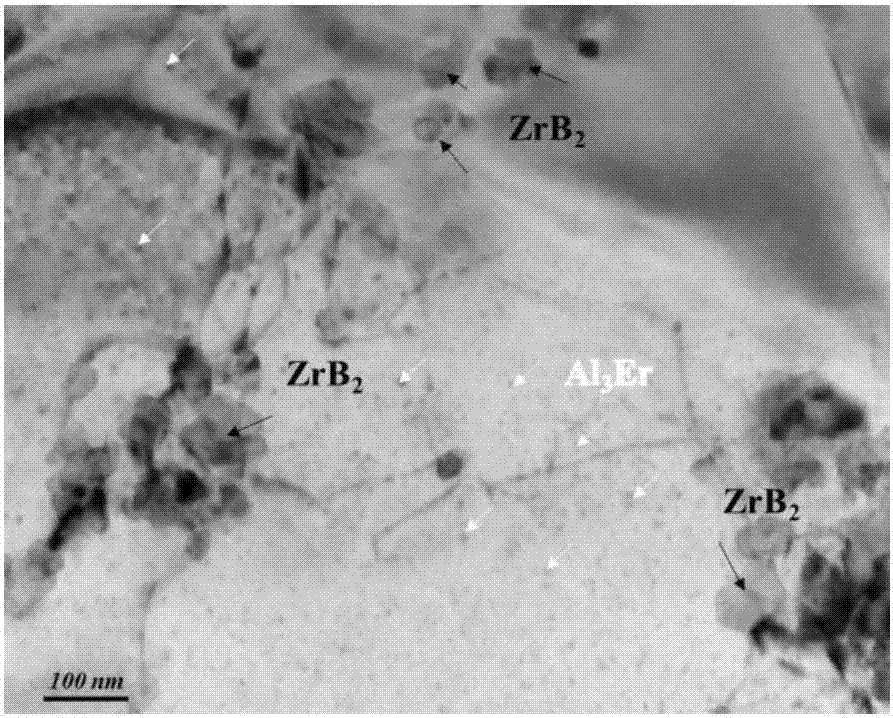

[0024] Transfer the melted 500Kg commercial AlSi9Cu3 alloy (760°C) into an intermediate holding furnace, then add Al-10Zr and Al-10B master alloys into the holding furnace and heat up to 850°C, while using a graphite stirring rotor to stir the melt to promote the alloy Mix thoroughly, keep the temperature for 15min, then cool the alloy to 750℃ and keep it warm; add Al-20Er, Al-20Fe, Al-10Mn, and pure Ni into the melt, stir and keep for 15min, then make the powder with particle size less than 500μm The complex refining agent is blown into the melt with inert gas through the hollow channel of the graphite rotor, and the melt is refined and degassed to remove the slag generated during the high-temperature melting and reaction of ...

Embodiment 2

[0028] Using Al-10Zr, Al-5B, Al-10Er, Al-10Fe, Al-10Mn master alloys and pure Ni, pure Mg, pure Zn, and AlSi9Cu3 as raw materials, the optimized nonlinear high pressure die-casting technology is used to prepare automobile engine reduction Vibration shell (the shell structure is complex and difficult to fill and exhaust gas, usually reduce Mg content, increase die-casting pressure, improve die-casting performance and yield).

[0029] Transfer the melted 500Kg commercial AlSi9Cu3 alloy (750°C) into an intermediate holding furnace, then add Al-10Zr and Al-5B master alloys into the holding furnace and raise the temperature to 840°C, while using a graphite stirring rotor to stir the melt to promote the alloy Mix thoroughly, hold time for 10min, then cool the alloy to 740℃ and keep it warm; add Al-10Er, Al-10Fe, Al-10Mn, and pure Ni into the melt, stir and keep for 10min, then make the powder with particle size less than 500μm The complex refining agent is blown into the melt with iner...

Embodiment 3

[0033] Using Al-10Zr, Al-5B, Al-20Er, Al-20Fe, Al-5Mn master alloys and pure NIi, pure Mg, pure Zn, and AlSi9Cu3 as raw materials, using optimized nonlinear high pressure die casting technology to prepare automobile engine oil pumps case.

[0034] Transfer the melted 500Kg commercial AlSi9Cu3 alloy (780℃) into an intermediate holding furnace, then add Al-10Zr and Al-5B master alloys into the holding furnace and raise the temperature to 860°C, while using a graphite stirring rotor to stir the melt to promote the alloy Mix thoroughly, hold time for 15min, then cool the alloy to 750℃ and keep it warm; add Al-20Er, Al-20Fe, Al-50Mn and pure Ni into the melt, stir and hold for 10min, then refine the ultra-fine powder The inert gas for the agent is blown into the melt through the hollow channel of the graphite rotor, and the melt is refined and degassed to remove the slag and hydrogen dissolved in the melt during high-temperature smelting and reaction of the alloy. The refining time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com