Process for preparing high-strength antifatigue optical fibre

A technology of waveguide fiber and production process, applied in the field of production process of optical waveguide fiber, can solve the problems of large investment and low deposition efficiency, and achieve the effect of increasing tensile strength and fatigue resistance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

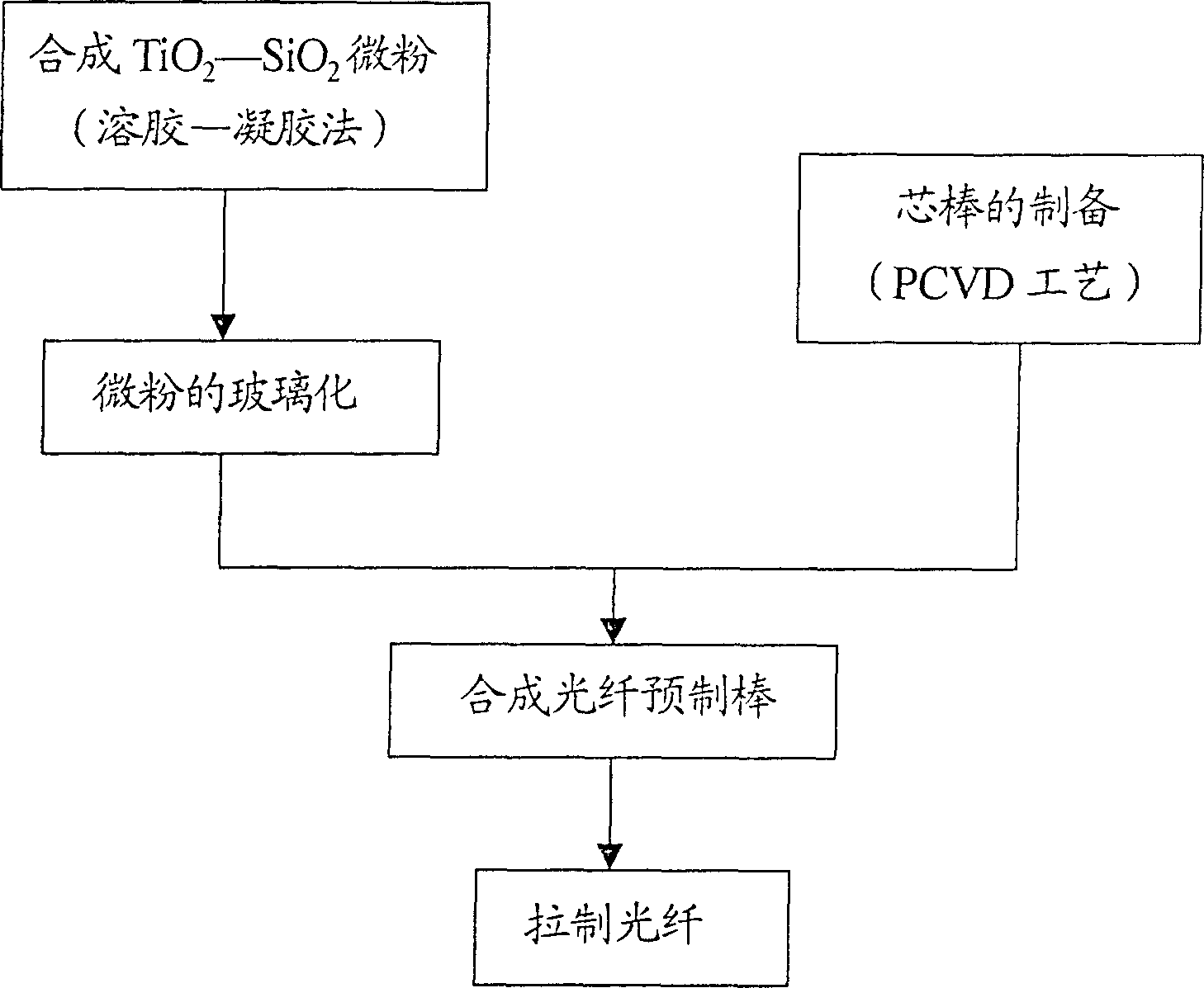

Method used

Image

Examples

Embodiment 1

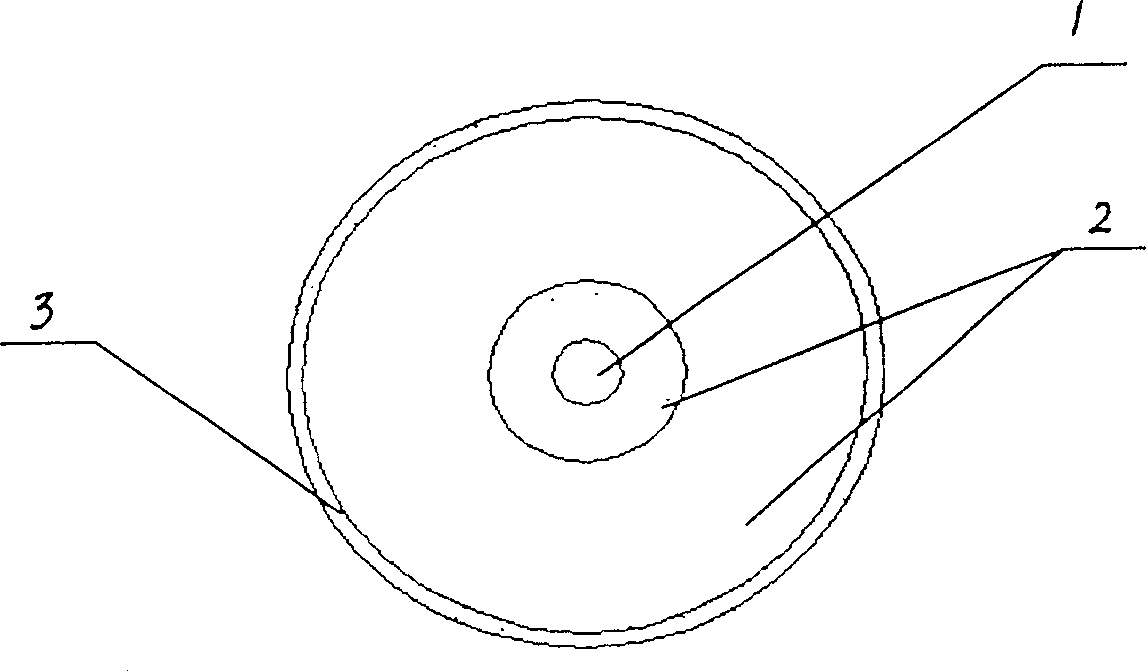

[0040] First prepare the titanium sol, then evenly disperse the quartz micropowder into the above titanium sol, adjust the pH value of the mixture to 5 by adding ammonia solution, wrap the colloid on the surface of the micropowder to form a gel mixture, remove the solution, and collect the gel mixture, Rinse with deionized water, then dry at a temperature of 200°C, then rinse the dried powder, and then dry at a temperature of 200°C to obtain titanium-doped micropowder TiO without impurity ions. 2 -SiO 2 Powder is not. Put the titanium-doped micropowder in a high-frequency graphite electric furnace to melt at a temperature above 1800°C, and use a graphite mold to draw a titanium-doped quartz glass tube; use a plasma chemical vapor deposition process to make a titanium-doped quartz glass tube into a core rod ; The titanium-doped quartz glass tube and the mandrel are polished with an oxyhydrogen flame respectively, then soaked in an alkaline solution and an acidic solution respe...

Embodiment 2

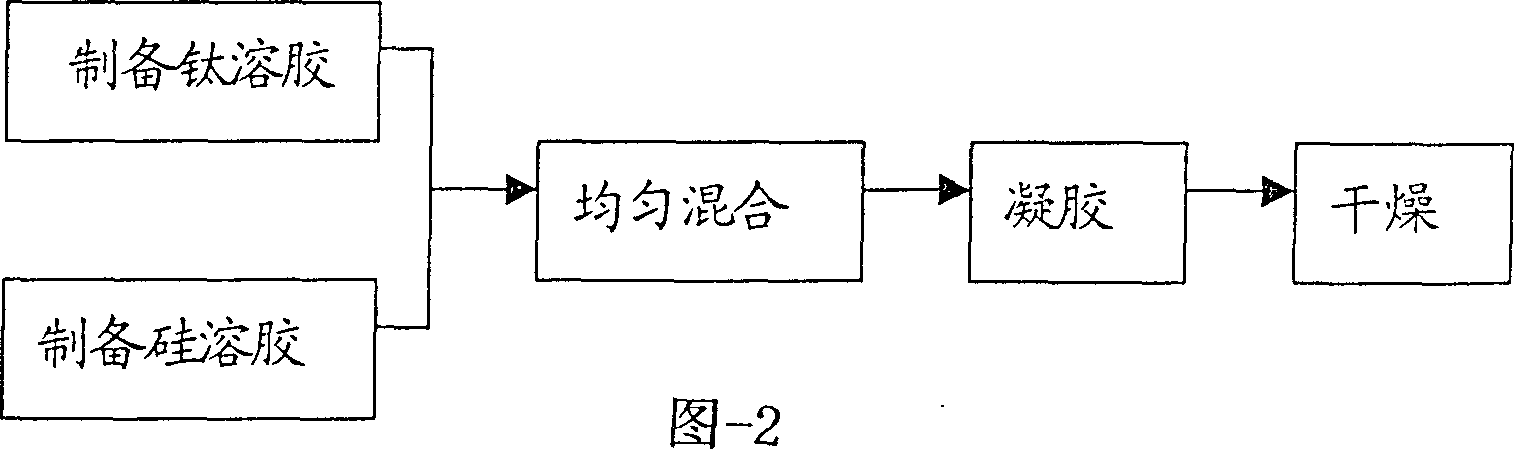

[0042] Prepare silica sol and titanium sol separately, and then add dilute acid solution to adjust the pH value of the mixed colloid to 1 while mixing the two sols, while stirring at high speed to make the mixture evenly mixed without flocculation, and then add ammonia solution to adjust The PH value of the mixed colloid is 4 until the colloid forms a gel, the solution is removed, the gel mixture is collected, rinsed with deionized water, and then dried at a temperature of 70°C. After drying, the dried powder is not rinsed, and then in Dry at a temperature of 70°C to obtain TiO without impurity ions 2 -SiO 2 powder. The titanium-doped micropowder is deposited on the outer surface of the high-purity quartz glass tube by gas refining method, and then the obtained glass tube is placed in an annealing furnace and treated with chlorine gas at 900°C for 30 hours for dehydration and stress relief. The titanium-doped quartz glass tube is made into a core rod by plasma chemical vapor...

Embodiment 3

[0044] High-purity silica sol and TiCl 3 Mix and stir at room temperature for 3 hours to obtain a part of the gel mixture, then add dilute sulfuric acid and dilute hydrochloric acid to flocculate the mixture, remove the solution, collect the gel mixture, rinse with deionized water, and then carry out at a temperature range of 500 ° C Drying, and then washing the dried powder, and then drying in the temperature range of 500 ° C, to obtain TiO without impurity ions 2 -SiO 2 powder. The titanium-doped micropowder is deposited on the outer surface of the high-purity quartz glass tube by gas refining method, and then the obtained glass tube is placed in an annealing furnace and treated with chlorine gas at 1200°C for 20 hours for dehydration and stress relief. The titanium-doped quartz glass tube is made into a core rod by plasma chemical vapor deposition; the titanium-doped quartz glass tube and the core rod are polished with a hydrogen-oxygen flame, respectively, and then soake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com