Construction method for building thermal-insulating wall

A construction method and technology for building thermal insulation, applied in thermal insulation, construction, building components, etc., can solve the problems of no noise reduction function, deformation and fracture of thermal insulation boards, single thermal insulation medium, etc., to achieve good thermal insulation and noise reduction effect and reduce usage. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A construction method for building thermal insulation walls, comprising the following process steps:

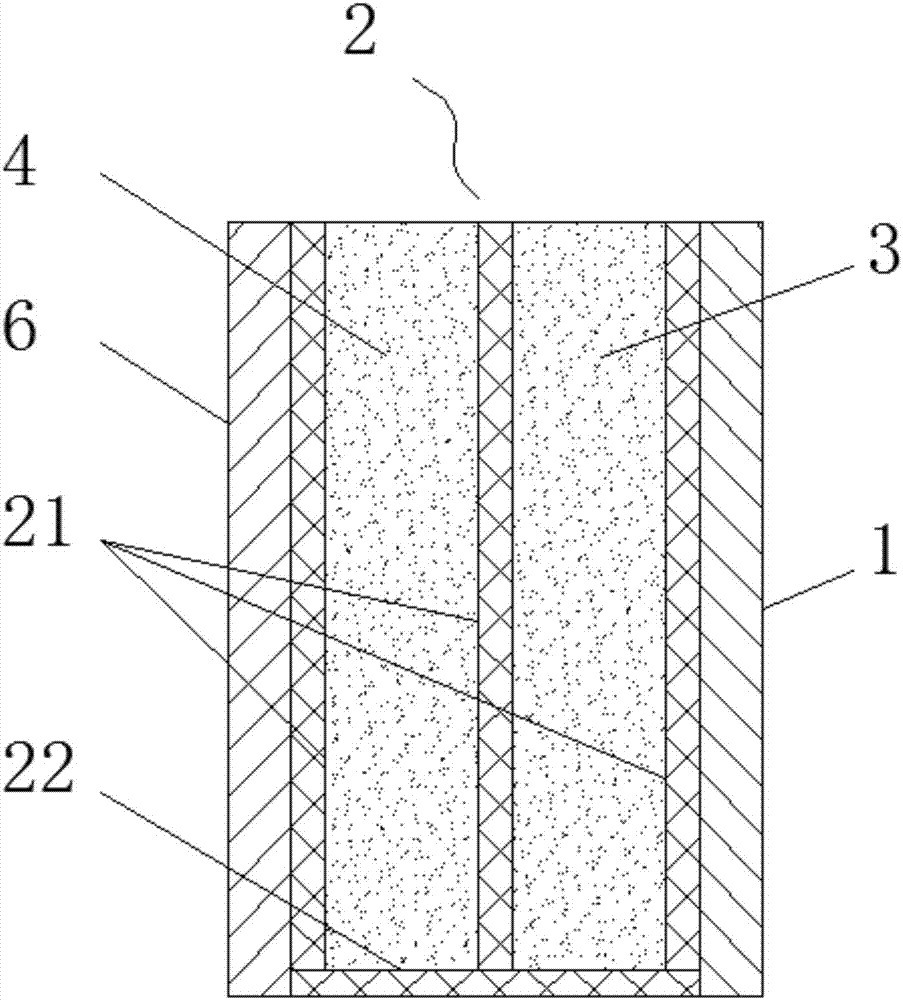

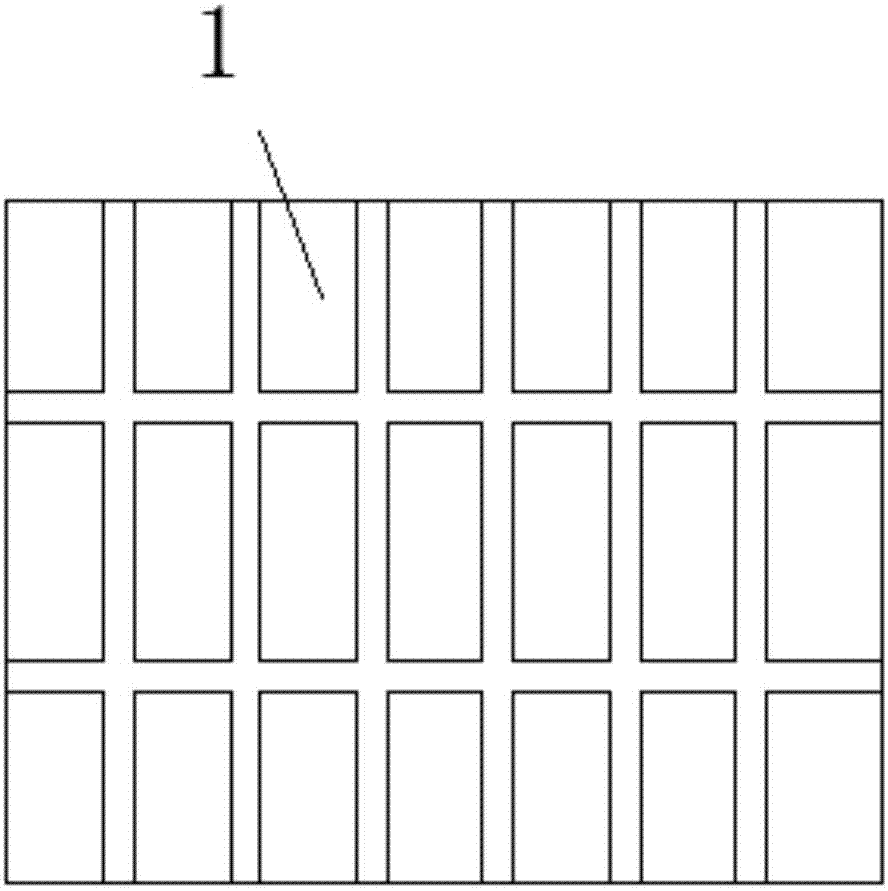

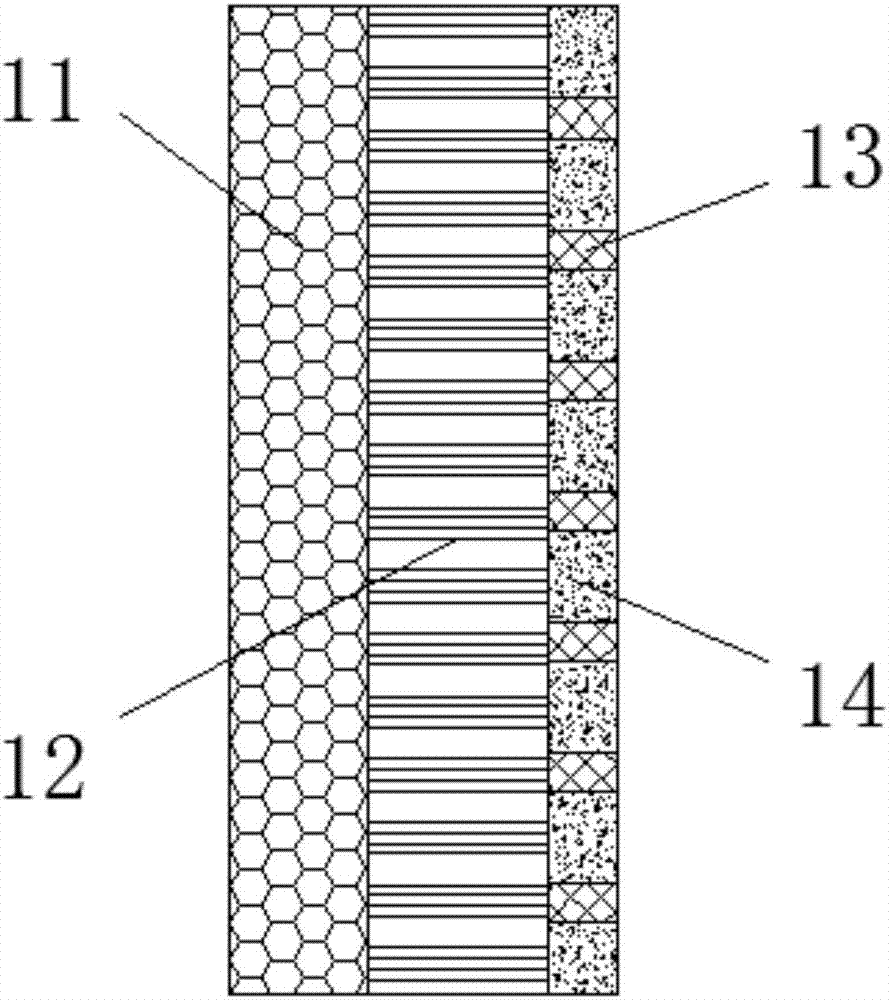

[0042] (1) The thermal insulation board 1 is fixed on the periphery of the reinforcement member 2 by the connector, and the wooden or metal formwork 6 is fixed on the inside of the reinforcement member 2, and the reinforcement member 2 consists of three layers of sides in the vertical direction. Consists of reinforcing bar assembly (21) and the underlying reinforcing bar assembly 22 at the bottom, and the lateral reinforcing bar assembly is connected by the underlying reinforcing bar assembly;

[0043] (2) The configured concrete slurry 4 and thermal insulation slurry 3 are respectively poured into the steel member 2 between the thermal insulation board 1 and the template 6 at the same time, wherein the concrete slurry and thermal insulation slurry are respectively located in the middle of the lateral steel bar assembly On both sides of the layer, the concrete slurry is ...

Embodiment 2

[0057] A construction method for building thermal insulation walls, comprising the following process steps:

[0058] (1) The thermal insulation board 1 is fixed on the periphery of the reinforcement member 2 by the connector, and the wooden or metal formwork 6 is fixed on the inside of the reinforcement member 2, and the reinforcement member 2 consists of three layers of sides in the vertical direction. Consists of reinforcing bar assembly (21) and the underlying reinforcing bar assembly 22 at the bottom, and the lateral reinforcing bar assembly is connected by the underlying reinforcing bar assembly;

[0059] (2) The configured concrete slurry 4 and thermal insulation slurry 3 are respectively poured into the steel member 2 between the thermal insulation board 1 and the template 6 at the same time, wherein the concrete slurry and thermal insulation slurry are respectively located in the middle of the lateral steel bar assembly On both sides of the layer, the concrete slurry i...

Embodiment 3

[0073] A construction method for building thermal insulation walls, comprising the following process steps:

[0074] (1) The thermal insulation board 1 is fixed on the periphery of the reinforcement member 2 by the connector, and the wooden or metal formwork 6 is fixed on the inside of the reinforcement member 2, and the reinforcement member 2 consists of three layers of sides in the vertical direction. Consists of reinforcing bar assembly (21) and the underlying reinforcing bar assembly 22 at the bottom, and the lateral reinforcing bar assembly is connected by the underlying reinforcing bar assembly;

[0075] (2) The configured concrete slurry 4 and thermal insulation slurry 3 are respectively poured into the steel member 2 between the thermal insulation board 1 and the template 6 at the same time, wherein the concrete slurry and thermal insulation slurry are respectively located in the middle of the lateral steel bar assembly On both sides of the layer, the concrete slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com