Superconducting tape packaging device

A technology for superconducting strips and packaging devices, which is applied in the manufacture/processing of superconductor devices, and can solve problems affecting product quality, burrs smashing insulation, silver and copper layers falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

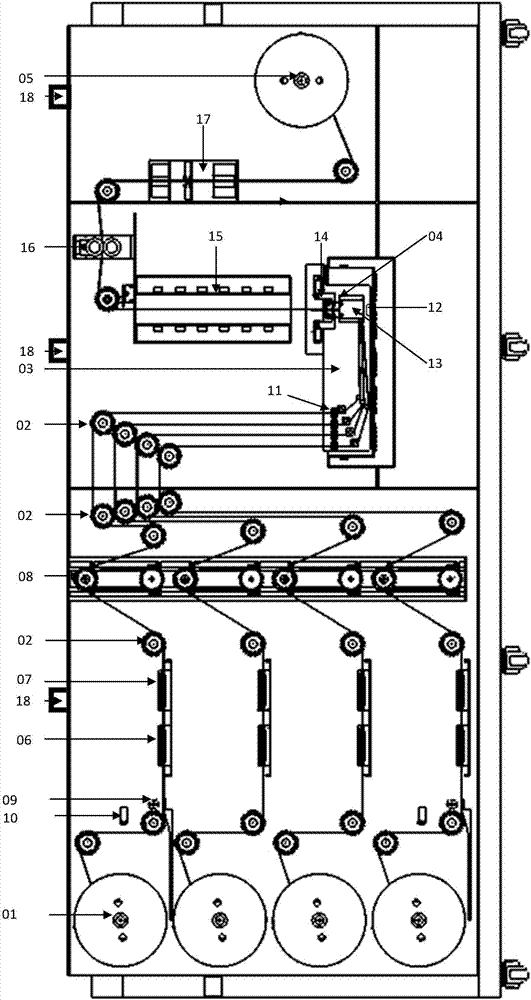

[0213] A superconducting tape packaging device, including a tape unwinding mechanism 01, a guide wheel mechanism 02, a furnace 03, an extrusion mechanism 04, and a winding mechanism 05; wherein:

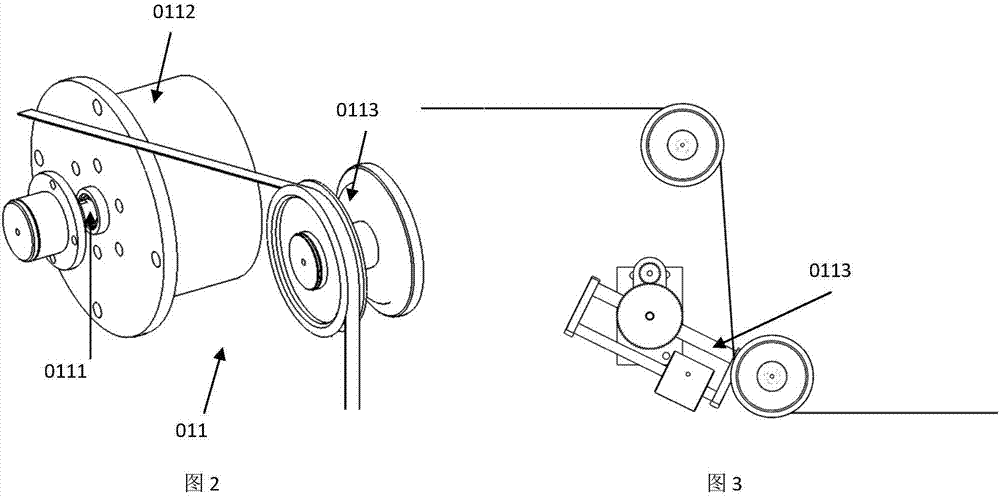

[0214] The strip unwinding mechanism 01 includes three or four independent independent unwinding mechanisms 011 . Two of the independent unwinding mechanisms 011 unwind the upper cladding strip and the lower cladding strip, and the other one or two unwinding mechanisms 011 unwind the superconducting strip.

[0215] The guide wheel mechanism 02 guides and locks the relative position of the strip.

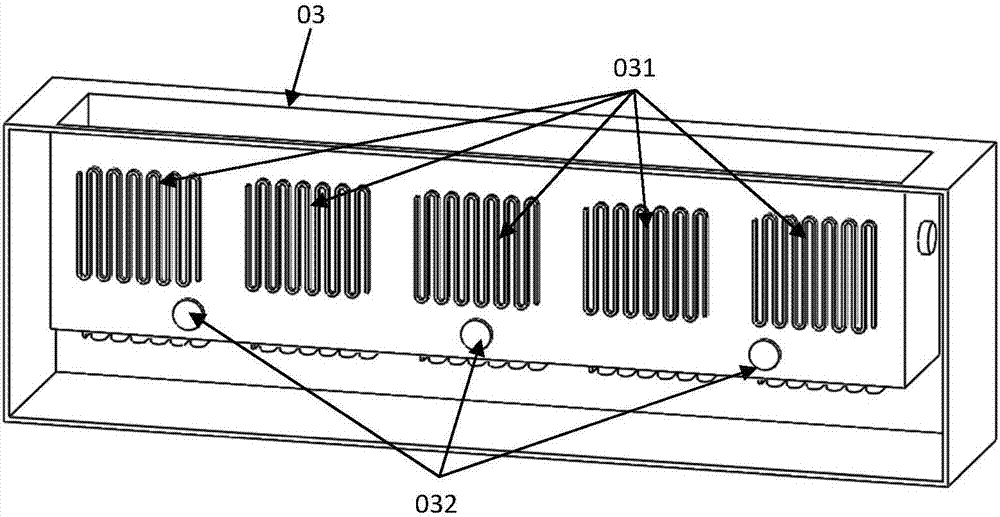

[0216] The furnace 03 can be lifted up and down. Equipped with electrically connected weld metal capable of heating the electrically connected weld metal to a molten state. When the strip is not encapsulated, the furnace 03 is electrically connected to the welding metal after descending and does not touch the strip. When the strip is packaged, after the rise, the furnace 03 is electrical...

Embodiment 2

[0226] Embodiment 2 is a modification example of Embodiment 1. On the basis of Embodiment 1, it may also include any one or more of the following components:

[0227] -The strip cleaning mechanism 06 is arranged between the strip unwinding mechanism 01 and the guide wheel mechanism 02, and is used to clean the surface of the upper cladding strip, the lower cladding strip and the superconducting strip;

[0228] - The flux coating mechanism 07 is set between the strip unwinding mechanism 01 and the guide wheel mechanism 02 or between the strip cleaning mechanism 06 and the guide wheel mechanism 02, and is used to coat the upper and lower cladding strips Surface flux coating of strip and superconducting strip;

[0229] - The tape storage mechanism 08 is arranged in the guide wheel mechanism 02, and is used to store a certain length of the upper cladding strip, the lower cladding strip and the superconducting strip;

[0230] - The spot welding mechanism 09 is arranged at the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com