Flexible perovskite solar energy cell blade coating preparation method

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that restrict the large-scale use of perovskite solar cells, the brittleness of glass substrates, and the limitation of perovskite, and achieve green The effect of low production and equipment requirements and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

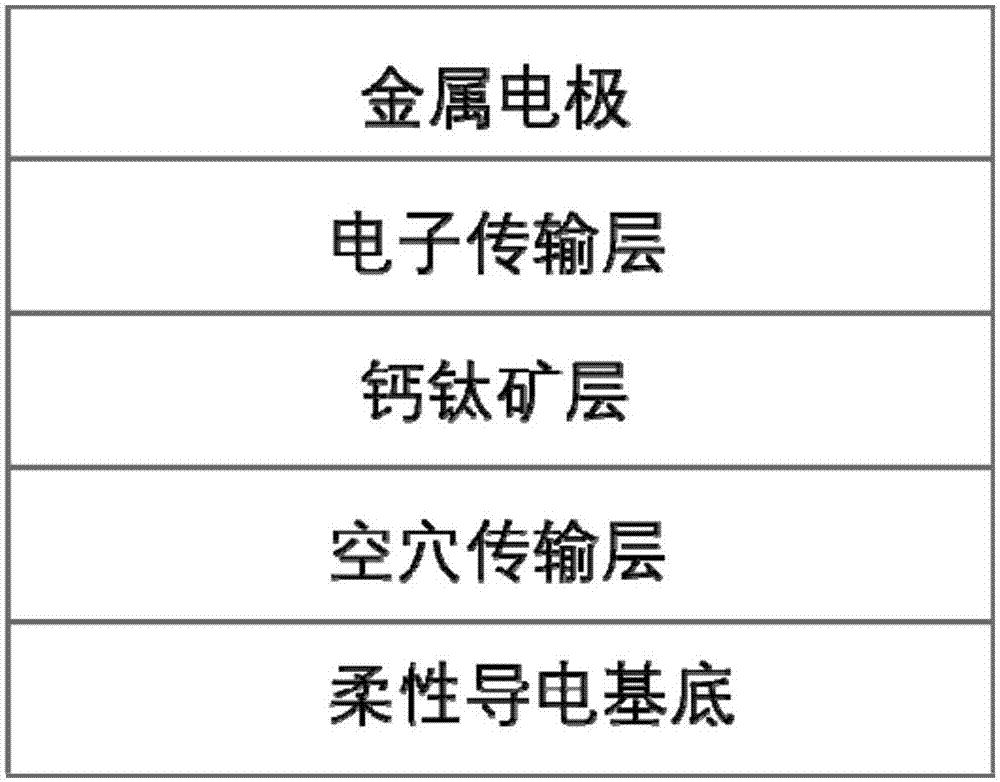

[0055] This embodiment provides a method for preparing a flexible perovskite solar cell by scraping coating. Specifically, a hole transport layer is first coated on a flexible substrate, and then a perovskite layer is coated on the basis of the hole transport layer as a photosensitive layer. , and then coat the electron transport layer on the perovskite layer, and finally vapor-deposit metal electrodes.

[0056] The structural schematic diagram of the flexible perovskite solar cell of this embodiment can be found in figure 1 .

[0057] preparation:

[0058] (1) On a flexible conductive substrate (1.5cm×1.5cm), 35 μL of the precursor solution of the hole transport layer ((PEDOT:PSS), PSSA and isopropanol were mixed at a mass ratio of 1:0.25:3 to obtain a mixture solution), and then annealed at 110° C. for 15 minutes to prepare a hole transport layer on a flexible conductive substrate;

[0059] Among them, when scraping, the flexible conductive substrate is heated at 60°C, th...

Embodiment 2

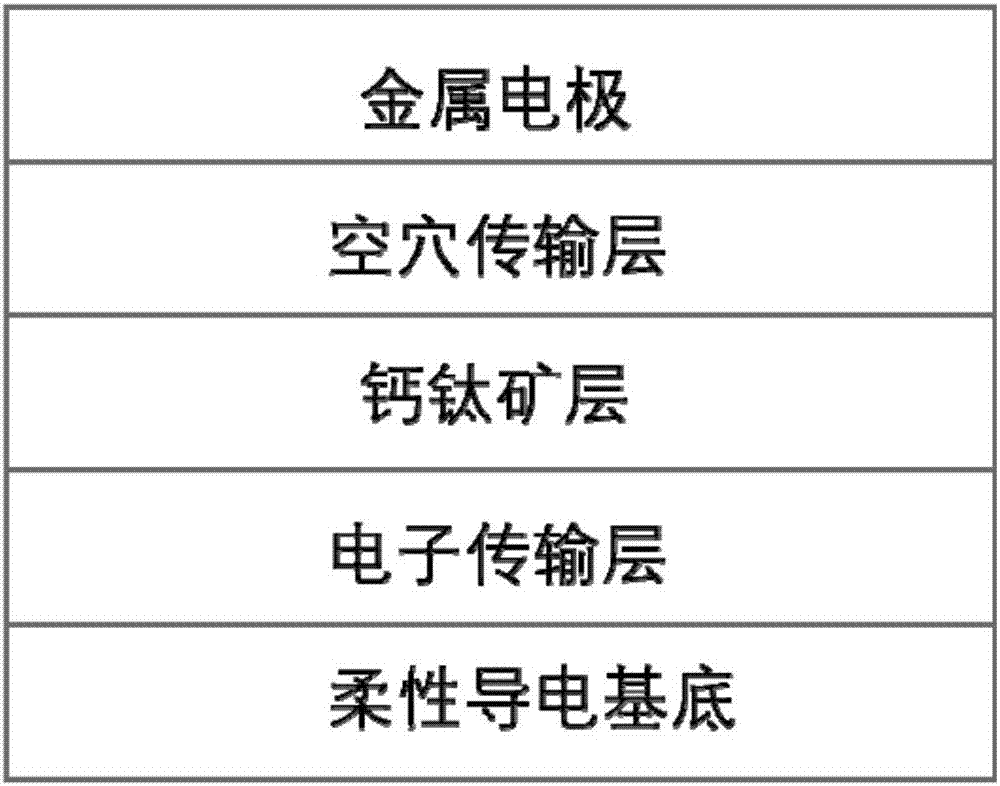

[0066] This embodiment provides a method for preparing a flexible perovskite solar cell by scraping coating. Specifically, an electron transport layer is coated on a flexible substrate, and then a perovskite layer is coated on the basis of the electron transport layer as a photosensitive layer, and then the A hole transport layer is coated on the perovskite layer, and finally a metal electrode is evaporated.

[0067] The structural schematic diagram of the flexible perovskite solar cell of this embodiment can be found in figure 2 .

[0068] (1) Scrape-coat 50 μl of electron transport layer solution (chlorobenzene solution of PCBM, concentration: 5 mg / ml) on a flexible conductive substrate (2cm×2cm), and then let it stand for 50 minutes to dry, thereby preparing electrons on a flexible conductive substrate. For the transport layer, select an area with uniform film formation and proceed to the subsequent steps;

[0069] Among them, when scraping, the temperature of the flexib...

Embodiment 3

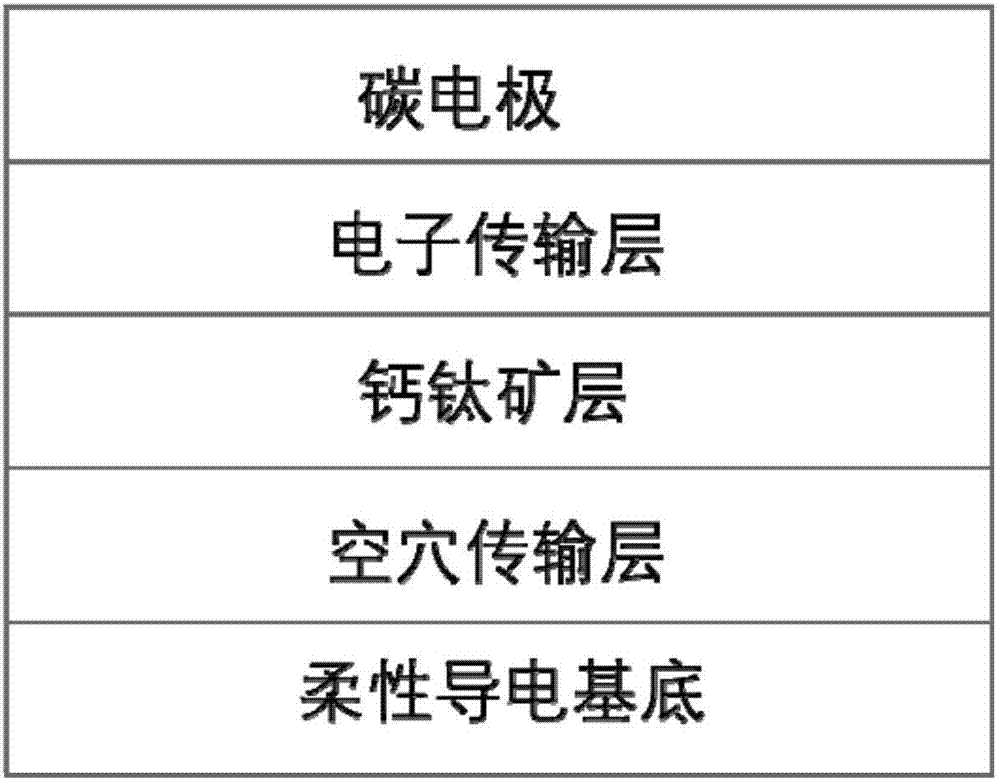

[0076] This embodiment provides a method for preparing a flexible perovskite solar cell by scraping coating. Specifically, a hole transport layer is first coated on a flexible substrate, and then a perovskite layer is coated on the basis of the hole transport layer as a photosensitive layer. , then coat the electron transport layer on the perovskite layer, and finally print the carbon electrode.

[0077] The structural schematic diagram of the flexible perovskite solar cell of this embodiment can be found in image 3 .

[0078] (1) Scrape-coat 30 μL of the precursor solution of the hole transport layer (a mixed solution of (PEDOT:PSS), PSSA and isopropanol at a mass ratio of 1:0.5:4) on a flexible conductive substrate (3cm×3cm) , and then annealed at 120°C for 18 minutes to prepare a hole transport layer on a flexible conductive substrate, select a region with uniform film formation, and proceed to the subsequent steps;

[0079] Among them, when scraping, the flexible conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com