Chain multi-port gird-connected interface device and control method

A technology of interface device and control method, applied in circuit devices, output power conversion devices, AC network circuits, etc., can solve the problems of low cost performance, complex structure, low reliability, etc., to maximize equipment utilization and flexible configuration , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

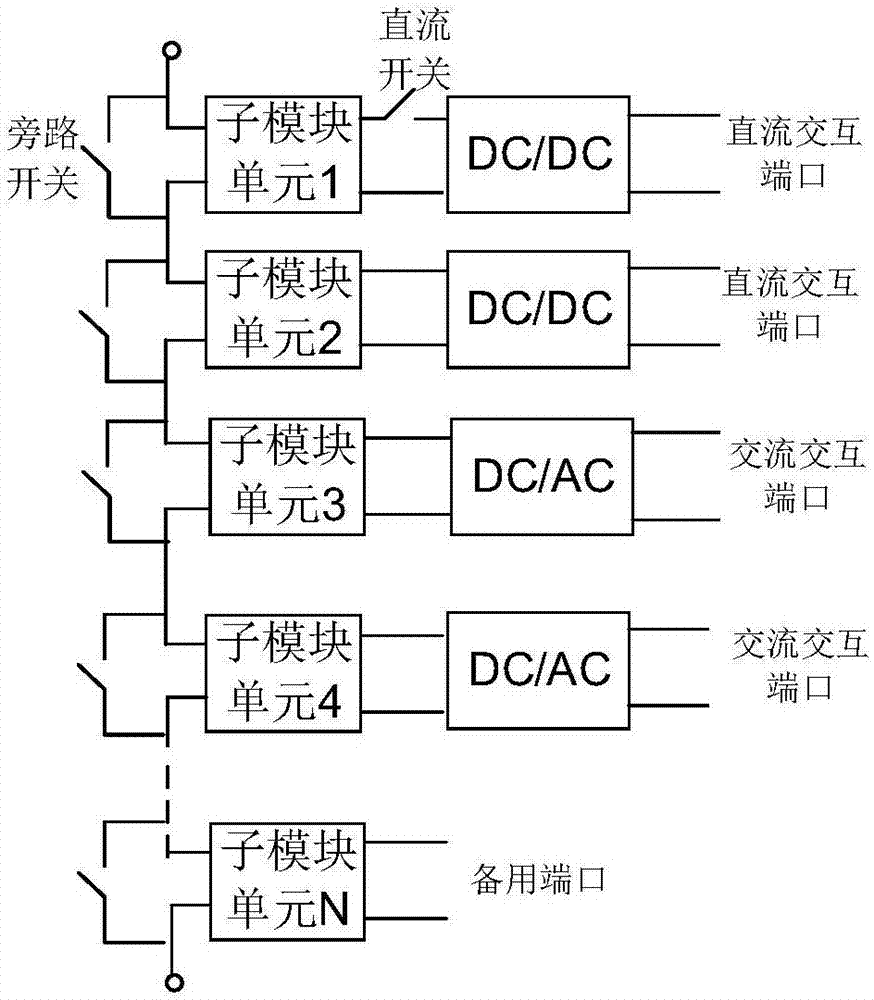

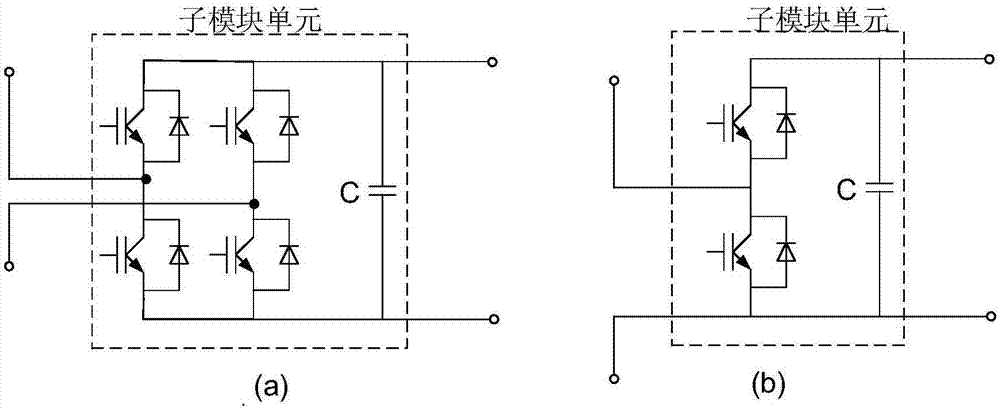

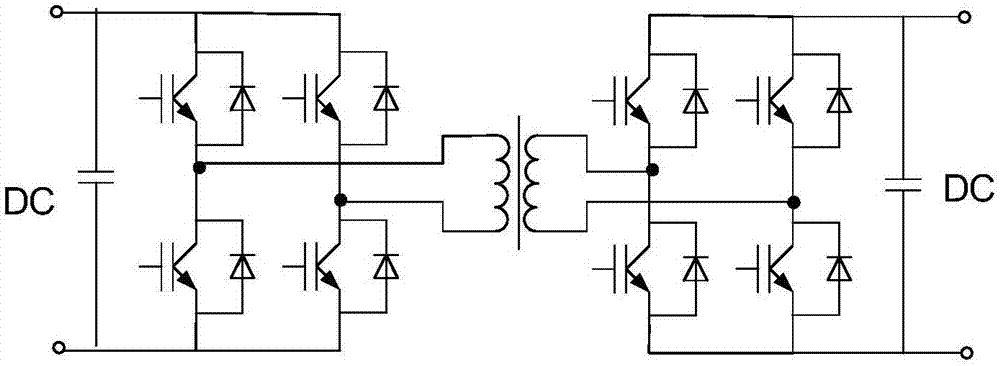

[0057] Such as figure 1 Shown: a chain-type multi-port grid-connected interface device, including a commutation chain, the commutation chain is composed of at least two sub-module units connected in series, and the sub-module units include power conversion units and capacitors. The positive pole and negative pole lead out are defined as the DC terminal of the sub-module unit. One end of the power conversion unit is connected in parallel with the capacitor, and the other end is defined as the AC terminal of the sub-module unit. The AC terminals of each sub-module are connected in sequence. The chain The multi-port grid-connected interface device also includes at least one DC converter and at least one DC-AC converter. The DC converter can convert one type of DC power into another DC power with different output characteristics. One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com