Biomimetic artificial spine prosthesis with flange

A technology of prosthesis and flange, applied in the field of medical artificial prosthesis, can solve the problem of complex and individualized spinal reconstruction surgery, low complexity and individualization of implants, artificial prosthesis implants It is difficult to use standard parts and other problems to achieve the effects of promoting healing and recovery, promoting bone cell growth, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

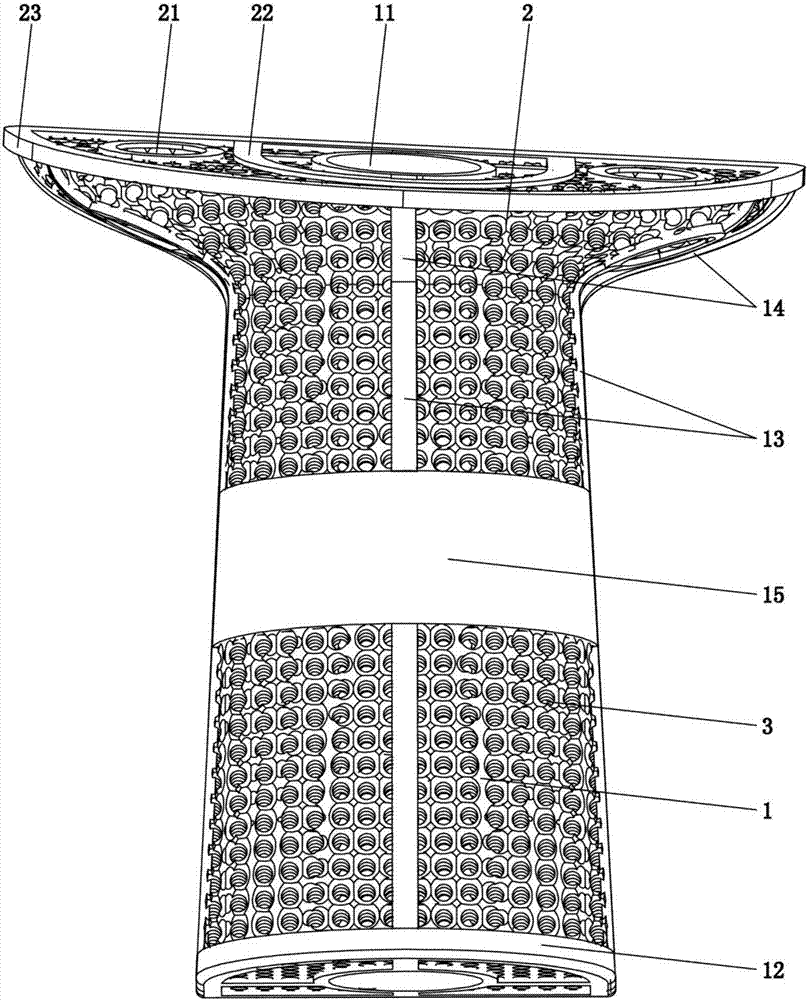

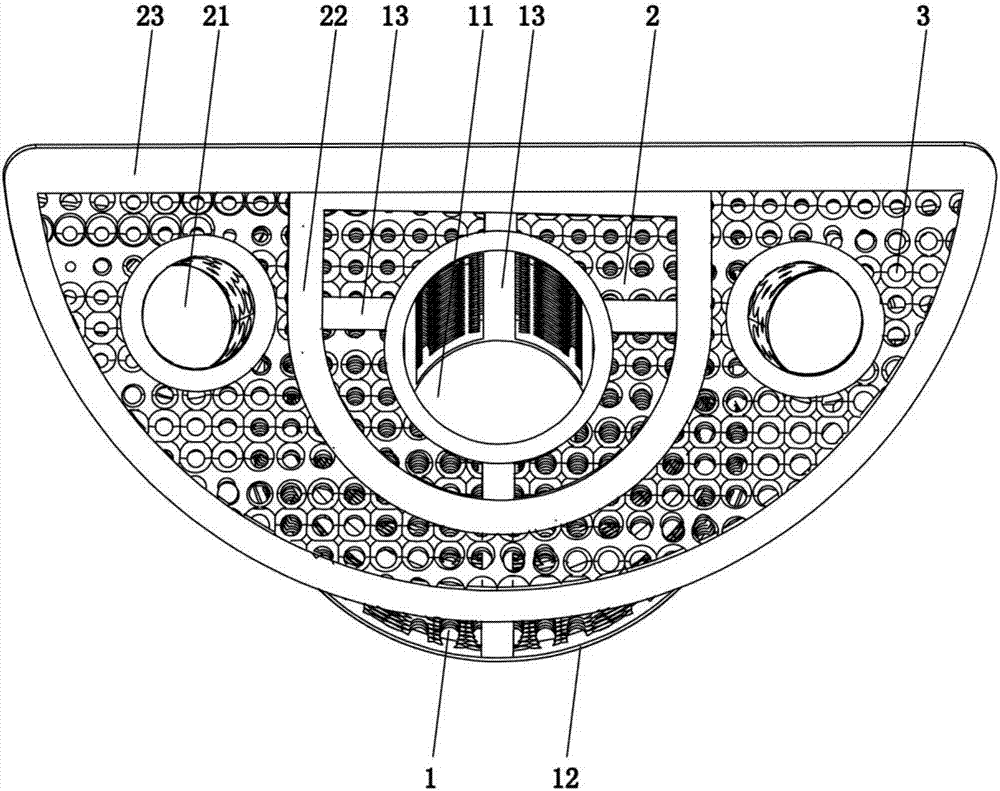

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0020] Such as figure 1 As shown, a bionic artificial spinal prosthesis with a flange according to the present invention includes a vertically arranged bionic prosthesis 1, the upper end of the bionic prosthesis 1 is provided with a flange body 2, and the flange body 2 Threaded holes 21 are provided on both ends of the bionic prosthesis 1 and the flange body 2. The bionic prosthesis 1 and the flange body 2 are integrated structures with micro-holes 3 constructed by 3D printing technology. The bionic prosthesis 1 and the flange body 2 are vertically provided with through The hole 11 and the two ends of the through hole 11 respectively pass through the lower end surface of the bionic prosthesis 1 and the upper end surface of the flange body 2; the bionic prosthesis 1 is used to replace the damaged spine after surgical resection, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com