A deep drawing method for vanadium alloy sheet metal

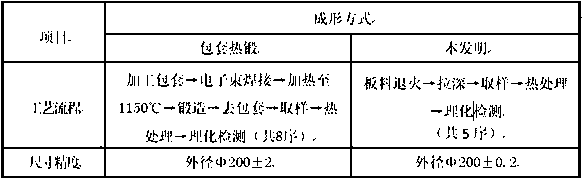

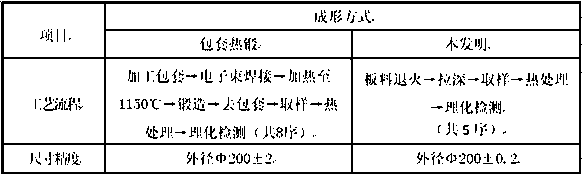

A technology for vanadium alloy and sheet material, which is applied in the field of deep drawing of vanadium alloy sheet material, can solve the problems of cracking and releasing toxic substances, poor plasticity of vanadium alloy, low product qualification rate, etc., so as to improve friction and stress state. , the friction force is stable, and the effect of avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The deep-drawing forming process of vanadium alloy sheet is as follows: first, design the drawing part according to the vanadium alloy part, then design the mold and the stock according to the size of the drawing part. Vanadium alloy material strength and friction coefficient select the cushion material, and determine the cushion thickness according to the thickness of the vanadium alloy material. In this embodiment, a 3mm thick 0Cr18Ni9 stainless steel plate is selected. Shape as follows:

[0018] Step a: Vacuum annealing of the vanadium alloy sheet, the vacuum degree is 0.1 Pa, the annealing temperature is 950° C., and the temperature is kept for 1 hour.

[0019] Step b: The thickness of the stainless steel backing plate in step b: 3 mm.

[0020] Step c: Assemble the mould, the lubricant is animal oil, the animal oil is lard, the lubricating part of the mold is the working part of the die, and the lubricating part of the sheet metal is the contact part between the up...

Embodiment 2

[0026] The deep-drawing forming process of vanadium alloy sheet is as follows: first, design the drawing part according to the vanadium alloy part, then design the mold and the stock according to the size of the drawing part. Vanadium alloy material strength and coefficient of friction select the cushion material, and determine the cushion thickness according to the thickness of the vanadium alloy material. In this embodiment, a 1mm thick 0Cr18Ni9 stainless steel plate is selected. Shape as follows:

[0027] Step a: Vacuum annealing of the vanadium alloy sheet, the vacuum degree is 0.01 Pa, the annealing temperature is 900° C., and the temperature is kept for 1 hour.

[0028] Step b: The thickness of the stainless steel backing plate in step b: 1 mm.

[0029] Step c: Assembling the mould, the lubricant is lubricated by machine oil, the lubricating part of the mold is the working part of the die, and the lubricating part of the sheet metal is the contact part between the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com