Multilayer printing process and pigment used for process

A multi-layer printing and process technology, applied in the printing process, the printing of special varieties of printed matter, the post-processing of printing, etc., can solve the problems of easy counterfeiting, increased production cost, easy oxidation, etc., and achieves isolation from air and moisture. The effect of saving and reducing anti-counterfeiting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

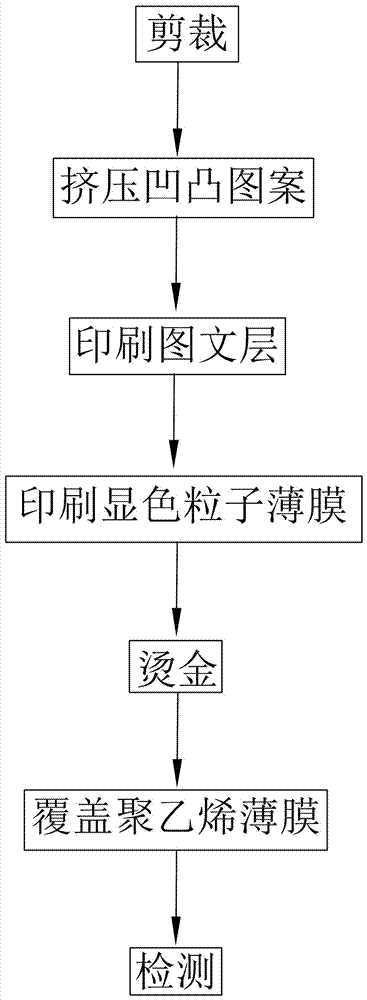

[0027] A kind of multi-layer printing process provided by the present invention comprises the following steps:

[0028] A. Cut the printing substrate according to the requirements;

[0029] B. Extruding the surface of the printed substrate cut in step A through a mold, so that the surface of the printed substrate forms a concave-convex pattern;

[0030] C. Print the ink containing high-gloss resin and wafer on the printing substrate with concave-convex pattern by at least one process of gravure printing, offset printing and offset printing to form a graphic layer;

[0031] D. Print at least one layer of color-developing particle film on the upper part of the graphic layer;

[0032] E. Perform bronzing treatment on the printed semi-finished product completed in step C;

[0033] F. Cover the surface of the bronzing-treated substrate with a polyethylene film by thermal lamination technology;

[0034] G. Detect the product of step E.

[0035] Add high-brightness resin and wafe...

Embodiment 2

[0046] A kind of pigment that is used for above-mentioned printing process, comprises the component of following parts by weight: 20 parts of resin liquid, 0.5 part of defoamer, 3 parts of emulsifier, 20 parts of glycerin, 15 parts of pigment, 8 parts of industrial ethanol, high gloss 60 parts of resin, 20 parts of wafer.

[0047]In this embodiment, except that the specific gravity of the formula of the pigment is different from that of the embodiment, the others are completely the same as the embodiment one.

Embodiment 3

[0049] A kind of pigment that is used for above-mentioned printing process, comprises the component of following parts by weight: 15 parts of resin liquid, 0.4 part of defoamer, 2.5 parts of emulsifier, 18 parts of glycerin, 12 parts of pigment, 6 parts of industrial ethanol, high gloss 45 parts of resin, 15 parts of chip.

[0050] In this embodiment, except that the specific gravity of the formula of the pigment is different from that of the embodiment, the others are completely the same as the embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com