Preparation method of highly dispersed silicon dioxide microsphere with controllable particle size

A silicon dioxide, high dispersion technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of long time, poor dispersion of silicon dioxide microspheres, etc., to achieve simple equipment, low external environment requirements, good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take 4.5mL tetraethyl orthosilicate and 45mL absolute ethanol and mix well;

[0034] (2) Take 20mL ammonia water, 16mL ethanol and 25mL deionized water and mix well;

[0035] (3) Put the solution obtained in the above step (2) into a constant temperature magnetic stirrer, set the temperature at 25°C, and the rotation speed at 1800rpm, then quickly add the solution obtained in step (1) into it, and reduce the rotation speed to 1000rpm after 1min. Then continue to react for 2h;

[0036] (4) After the reaction is completed, centrifuge and wash with deionized water for 3 times at a rotational speed of 3500 rpm for 8 min.

[0037] (5) Put the washed silica microspheres into a drying oven for drying at a temperature of 60°C.

[0038] (6) The dried silica microspheres were crushed with a glass rod, dissolved in DMF solution and ultrasonicated for 3 h.

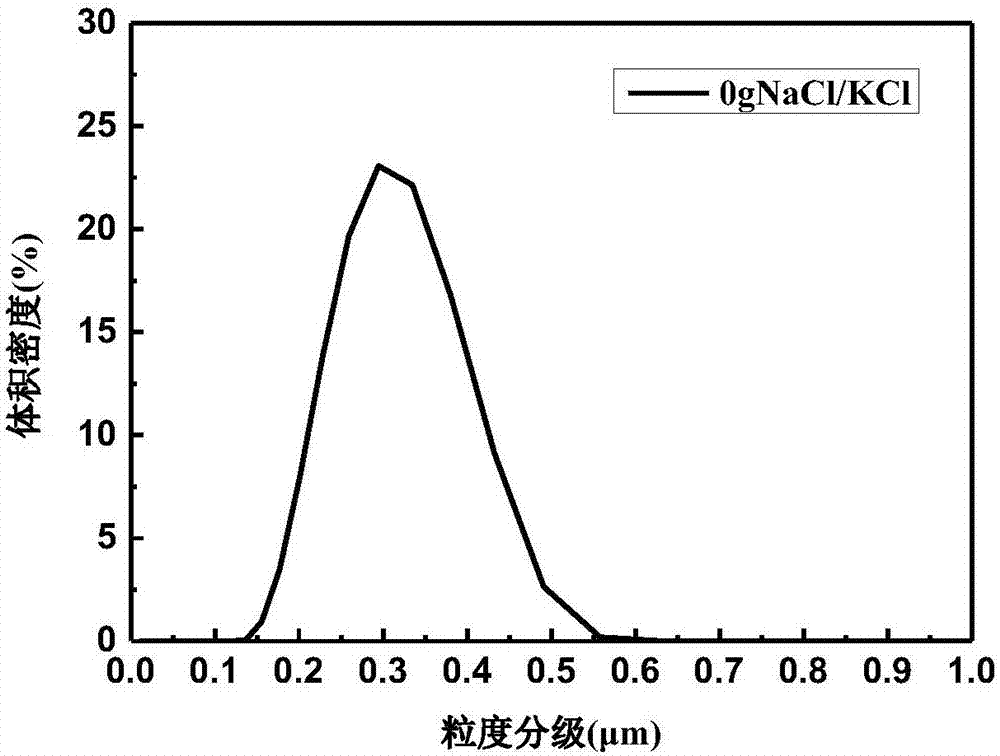

[0039] The particle diameter measured by laser particle size analyzer is 293nm, see figure 1.

Embodiment 2

[0041] (1) Take 4.5mL tetraethyl orthosilicate and 45mL absolute ethanol and mix well;

[0042] (2) Take 20mL ammonia water, 16mL ethanol and 25mL deionized water and mix well, then add 0.01gKCl;

[0043] (3) Put the solution obtained in the above step (2) into a constant temperature magnetic stirrer, set the temperature at 25°C, and the rotation speed at 1800rpm, then quickly add the solution obtained in step (1) into it, and reduce the rotation speed to 1000rpm after 1min. Then continue to react for 2h;

[0044] (4) After the reaction is completed, centrifuge and wash with deionized water for 3 times at a rotational speed of 3500 rpm for 8 min.

[0045] (5) Put the washed silica microspheres into a drying oven for drying at a temperature of 60°C.

[0046] (6) The dried silica microspheres were crushed with a glass rod, dissolved in DMF solution and ultrasonicated for 3 h.

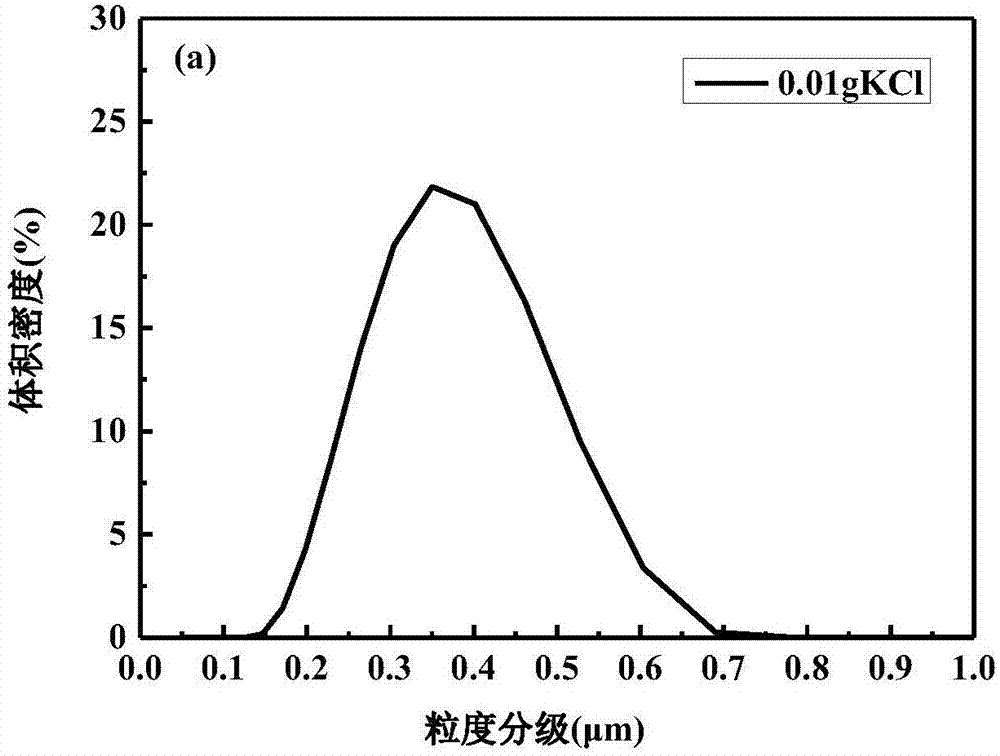

[0047] The particle diameter measured by laser particle size analyzer is 354nm, see figure 2 .

Embodiment 3

[0049] (1) Take 4.5mL tetraethyl orthosilicate and 45mL absolute ethanol and mix well;

[0050] (2) Take 20mL ammonia water, 16mL ethanol and 25mL deionized water and mix well, then add 0.02g KCl;

[0051] (3) Put the solution obtained in the above step (2) into a constant temperature magnetic stirrer, set the temperature at 25°C, and the rotation speed at 1800rpm, then quickly add the solution obtained in step (1) into it, and reduce the rotation speed to 1000rpm after 1min. Then continue to react for 2h;

[0052] (4) After the reaction is completed, centrifuge and wash with deionized water for 3 times at a rotational speed of 3500 rpm for 8 min.

[0053] (5) Put the washed silica microspheres into a drying oven for drying at a temperature of 60°C.

[0054] (6) The dried silica microspheres were crushed with a glass rod, dissolved in DMF solution and ultrasonicated for 3 h.

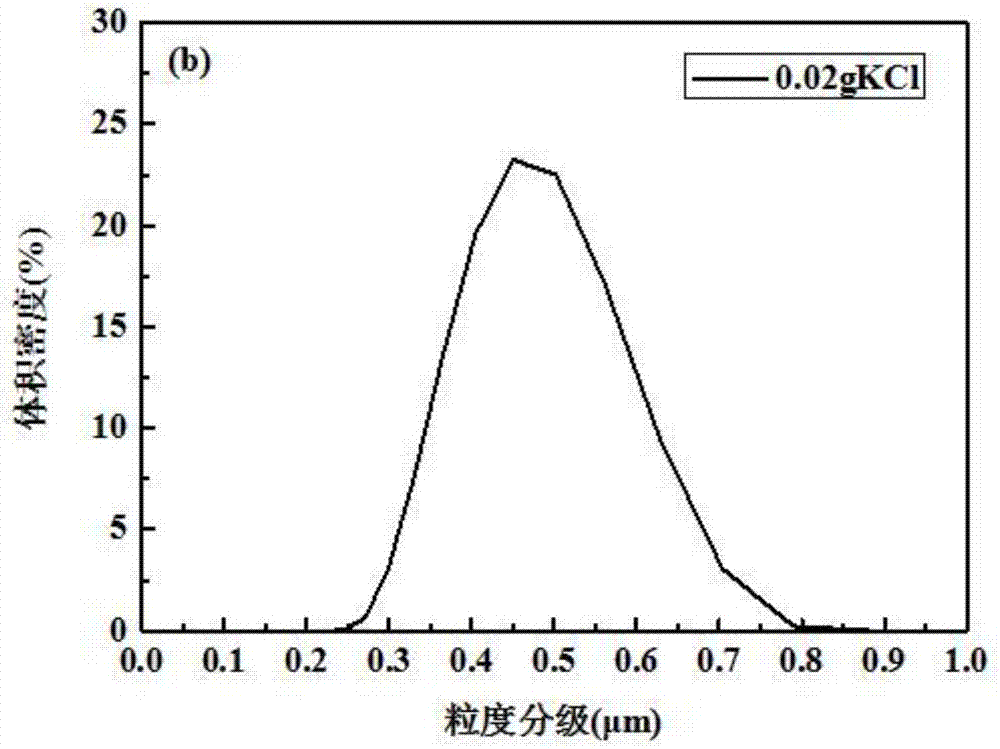

[0055] The particle size measured with a laser particle size analyzer is 459nm, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com