Printed circuit, thin film transistor and manufacturing method thereof

A technology for thin film transistors and printed circuits, applied to thin film transistors with operating voltages and their manufacturing fields, can solve problems such as reduced stability and shortened storage period, and achieve increased maintenance of electrical conductivity, increased heat resistance, improved stability and electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

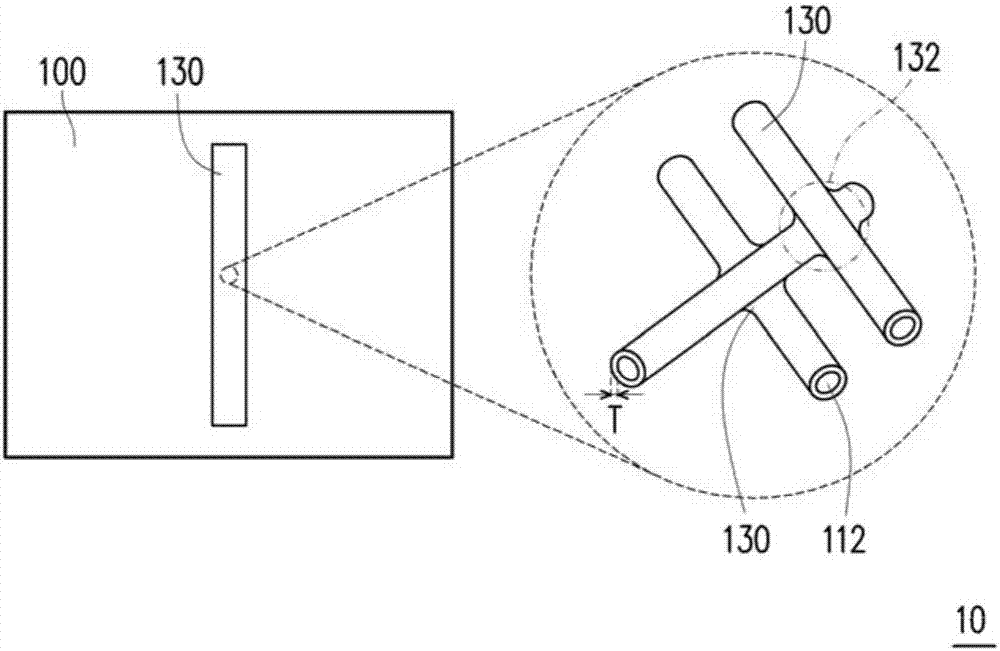

[0052] First, metallic ink containing silver nanowires is jet-printed on the substrate. Next, the metallic ink containing TiO 2 The colloidal composition of the precursor. Then, bake at 150 °C for 1 hour to remove the solvent and make the TiO 2 Precursors are reduced to TiO on the surface of silver nanowires 2 . So far, the substrate with TiO 2 Protective film for printed lines.

[0053] picture 5A It is a scanning electron micrograph of silver nanowires before printing the colloidal composition. picture 5B It is a scanning photo of the silver nanowires after spray printing the colloidal composition and baking. Depend on picture 5B It can be seen that after the spray-printed colloidal composition is baked, the colloid will not only form on the surface of the nano-silver wire, but also gather at the junction of the nano-silver wire, which contributes to the separation between adjacent nano-silver wires. bonding, thereby improving the stability and conductivity of...

example 2

[0055] Example 2 (jet printing metal ink and containing TiO 2 Colloidal composition of precursors)

[0056] First, metallic ink containing silver nanowires is jet-printed on the substrate. Next, the metallic ink containing TiO 2 The colloidal composition of the precursor. Then, a heating process is performed to remove the solvent. Next, after baking at 400° C. for 1 hour, the state of the silver nanowires was observed using a scanning electron microscope.

example 3

[0064] First, metallic ink containing silver nanowires is jet-printed on the substrate. Next, the metallic ink containing TiO 2 The colloidal composition of the precursor. Then, a heating process is performed to remove the solvent. Afterwards, after baking at 25°C, 50°C, 100°C, 150°C, 200°C, 250°C, 300°C, and 400°C for 1 hour, measure the sheet resistance of the silver nanowires with a protective film at each temperature point .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com