Electrolyte and lithium-ion battery

A technology of electrolyte and lithium salt, applied in the field of electrolyte and lithium ion battery, can solve the problems of bad influence on the interface stability of positive and negative electrodes, failure of lithium ion battery, increase of electrode surface impedance, etc., to improve power performance and lithium evolution. conditions, improving the cycle performance at room temperature and high temperature, and reducing the effect of DCR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

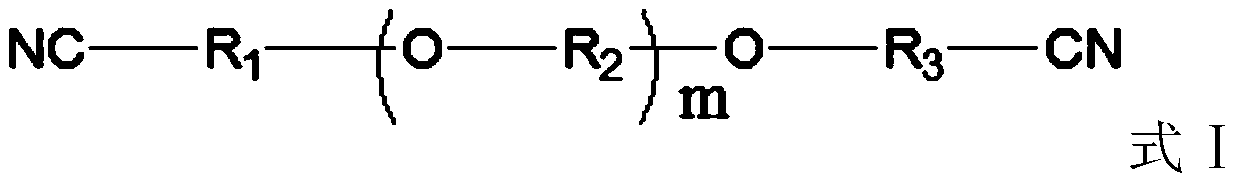

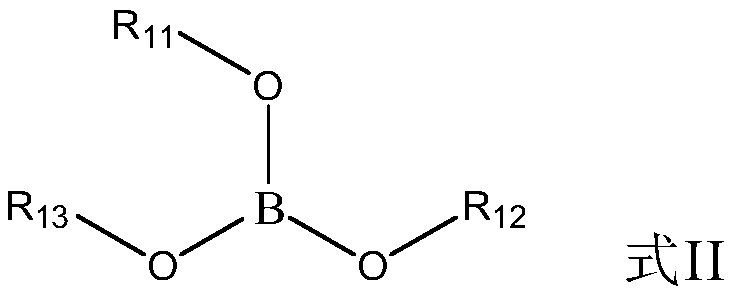

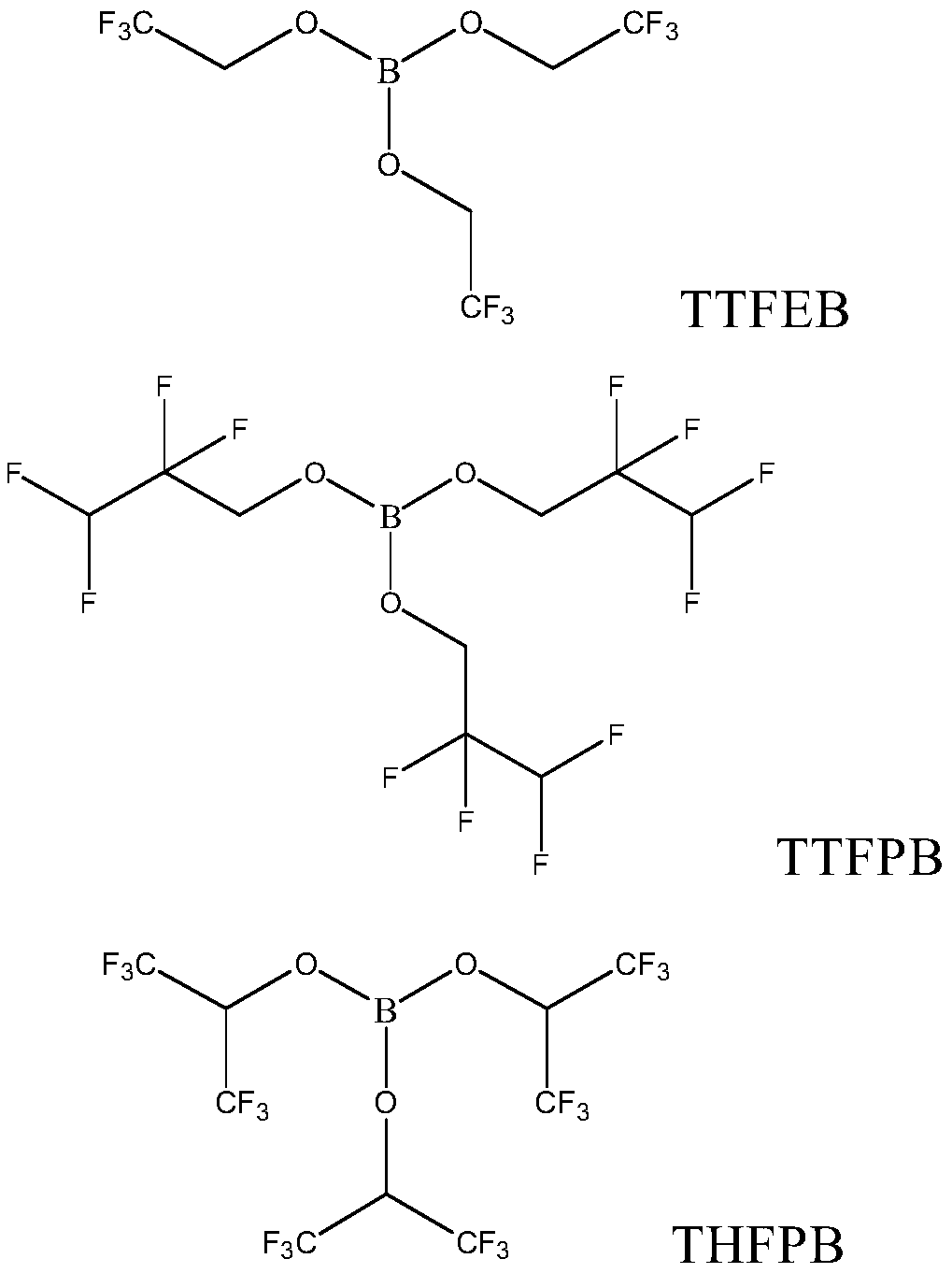

Method used

Image

Examples

preparation example Construction

[0043] (1) Preparation of electrolyte

[0044] Ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mixed with mass ratio EC:EMC:DEC=30:50:20, as non-aqueous organic solvent, to non-aqueous organic solvent After adding additives to the non-aqueous organic solvent after mixing evenly, the concentration of lithium salt is 1.1mol / L, which is the electrolyte solution.

[0045] In Examples 1-18 and Comparative Examples 1-6, the additives used and their addition amounts are shown in Table 1, wherein the addition amount of each additive in Table 1 is calculated based on the total mass of the electrolyte mass percentage.

[0046] The parameters of the electrolyte of table 1 embodiment 1-18 and comparative example 1-6

[0047]

[0048]

[0049] Note: "-" indicates that no substance is added.

[0050] (2) Preparation of positive electrode sheet:

[0051] The cathode active material LiNi 0.8 co 0.15 Al 0.05 o 2 , conductive agent Super P, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com