Plane polisher

A plane grinding and backside technology, which is applied in the direction of grinding devices, grinding machine tools, grinding machines, etc., can solve the problems of increased weight of optical measuring devices, difficulty in maintaining balance, and complicated structure, so as to prevent uneven contact and stabilize grinding Processing, to achieve the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

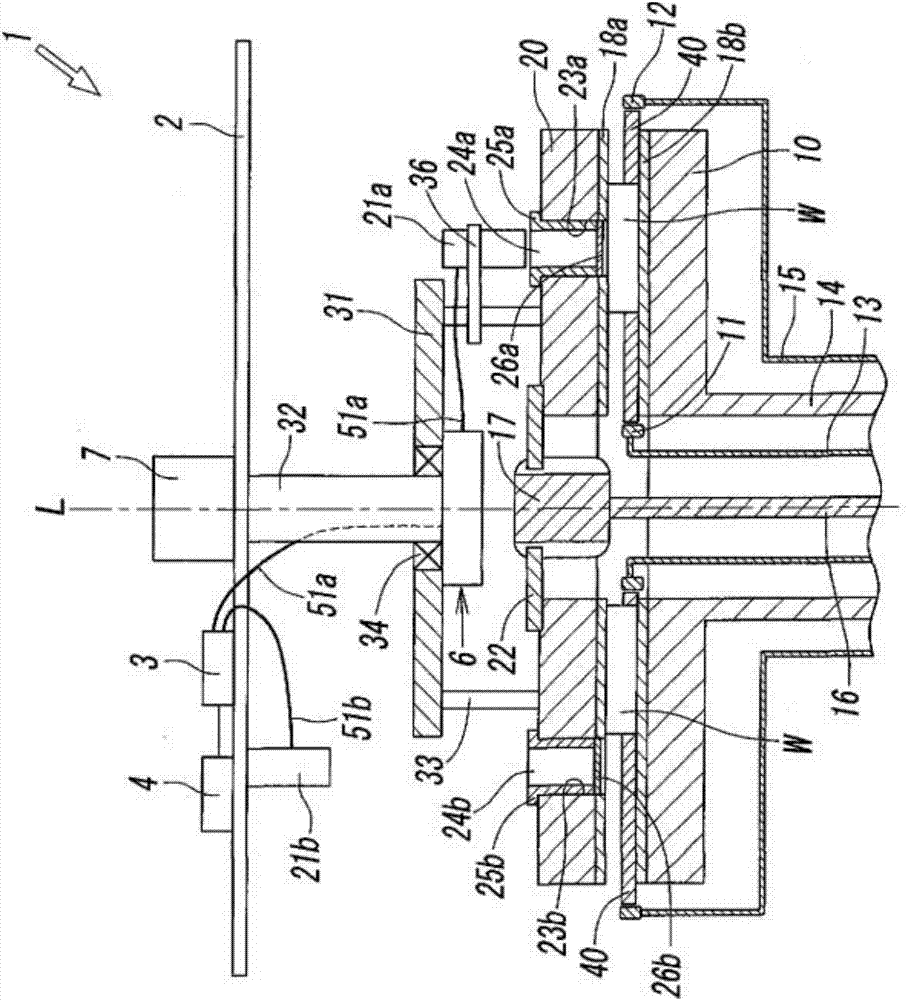

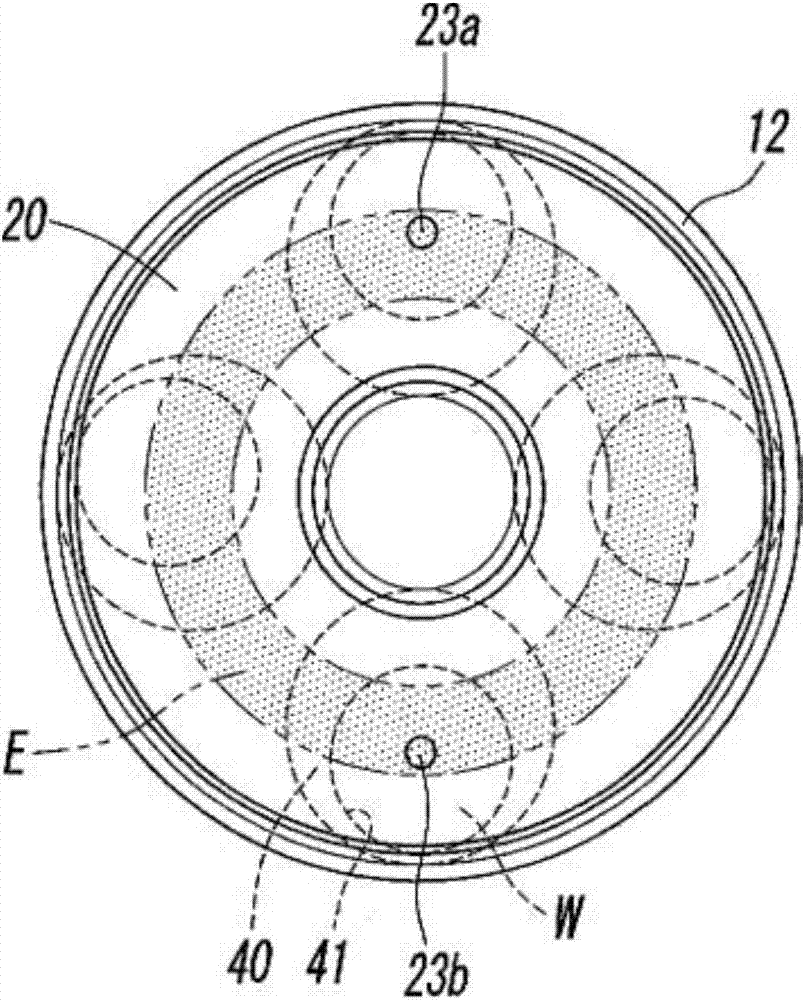

[0035] The surface polishing apparatus 1 of the present embodiment is used for polishing both surfaces of a plate-shaped workpiece W having light transmission (transparency) such as a silicon wafer, a sapphire wafer, a ceramic wafer, a crystal wafer, a glass substrate, and the like. Grinding is performed, which has: a lower fixed plate 10 rotatably supported on the machine body 2; an upper fixed plate 20 freely lifted and rotatably supported on the machine body 2; and a workpiece ground by the upper fixed plate 20 and the lower fixed plate 10 W's star wheel 40. On the lower surface of the last fixed disk 20 and the upper surface of the lower fixed disk 10, grinding pads 18a, 18b are pasted, but it is also possible to replace the grinding pads 18a, 18b for the structure of pasting abrasive grains, or the surface of the fixed disk itself is a grinding surface. structure.

[0036] A sun gear 11 is disposed at the center of the lower fixed plate 10 , and an internal gear 12 is di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap