A kind of negative liquid crystal compound and preparation method thereof

A technology of negative liquid crystals and compounds, applied in the field of negative liquid crystal compounds and their preparation, can solve the problems of poor miscibility, low resistivity, and limited application range, etc., achieve negative dielectric anisotropy performance improvement, and reduce driving voltage , good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

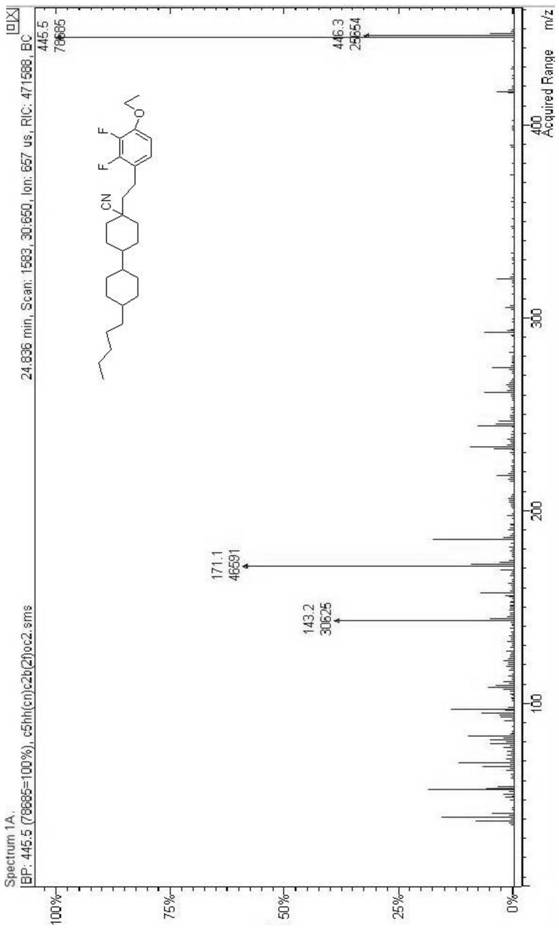

Embodiment 1

[0083] Embodiment 1, preparation

[0084] (1) Put 58.5g of 2,3-difluorophenetole (compound a-1), 42g of potassium tert-butoxide and 500ml of tetrahydrofuran into a 1000ml four-necked bottle. Under the protection of nitrogen, lower the temperature to -90~-100°C, add 200ml of 2.5mol / L butyllithium solution dropwise, and then keep the temperature for 1.5h. Add 30g of N,N-dimethylformamide dropwise at -90~-100°C. Slowly rise to room temperature and stir for 3h. The feed solution was poured into hydrochloric acid ice water for hydrolysis, extracted with ethyl acetate, dried, and passed through a silica gel column to obtain 4-ethoxy-2,3-difluorobenzaldehyde (compound 1-1) with a purity of 97.5% (GC), Yield 84%. Its reaction formula is as follows:

[0085]

[0086] (2) Put 162g of chloromethyl ether triphenylphosphine salt and 500ml of tetrahydrofuran into a 1000ml four-necked bottle. Under the protection of nitrogen, 58 g of potassium tert-butoxide was added at 0°C, and th...

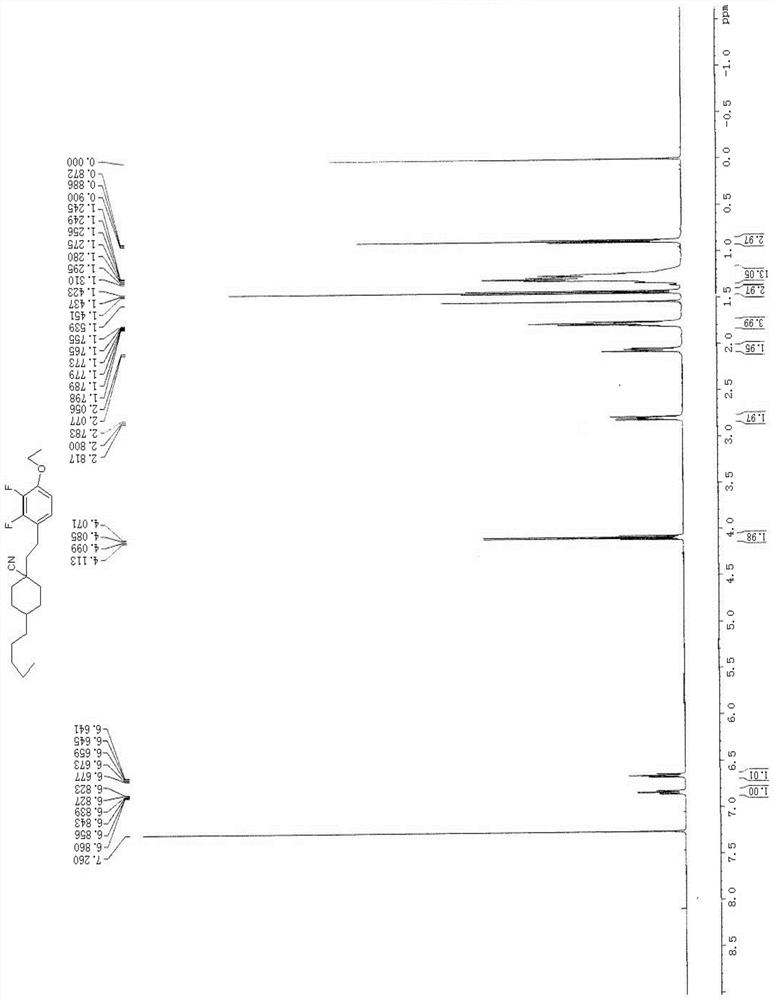

Embodiment 2

[0097] Embodiment 2, preparation

[0098] (1) Prepare intermediate-1 shown in the following formula according to the method of Example 1;

[0099]

[0100] (2) Add compound b-2, diisopropylamine and 100 ml of tetrahydrofuran into a 500 ml four-necked bottle. Under nitrogen protection, cool down to -50~-60°C, add butyllithium dropwise, and keep warm for 1h. Control the temperature at -50~-60°C, add the intermediate prepared in step (1) dropwise, wherein the molar ratio of intermediate-1, compound b-2, diisopropylamine and butyllithium is 1:1.1:1.3 : 1.25, dropwise rose to room temperature and stirred for 2h. Pour into acid water for hydrolysis, extract with ethyl acetate, neutralize, dry, and evaporate the solvent to dryness. Use petroleum ether to pass through a silica gel column and crystallize with ethanol to obtain the above product. (Mp:95.83-97.66℃, cp:150.75-152.0℃)

[0101]

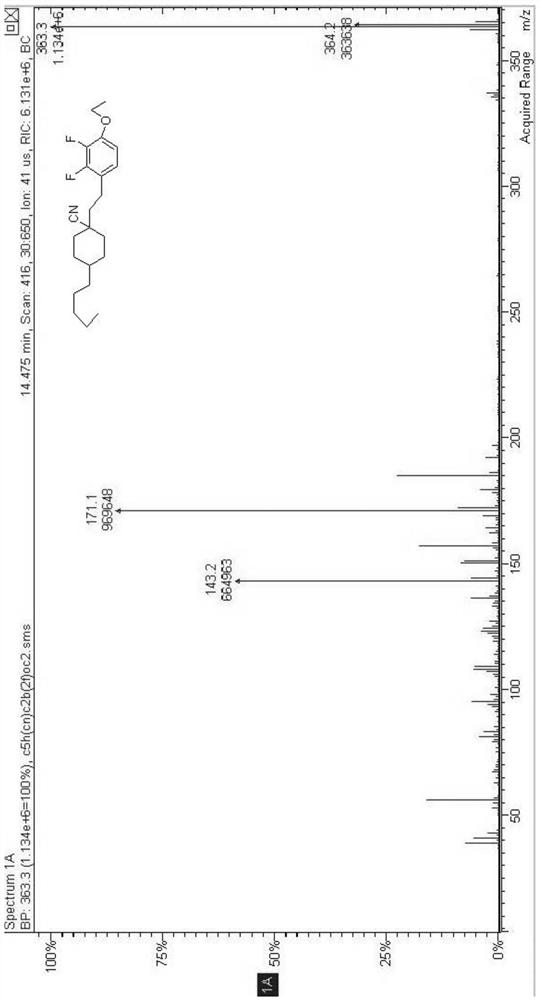

Embodiment 3

[0102] Embodiment 3, preparation

[0103] (1) with For raw material, prepare intermediate according to the method for embodiment 1

[0104] (2) to (Compound b-3) as a raw material, according to the method of Example 2 and the intermediate obtained in step (1), carry out a stirring reaction for 4h to obtain the above product, wherein the intermediate, compound b-3, diisopropylamine and butyl The molar ratio of base lithium is 1:1.0:1.2:1.20. (Product MP:74.05-74.88℃ cp:77.64-79.59℃)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com