Method for comprehensive utilization of cyperus esculentus meal

A kind of technology of oily bean meal and oily bean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

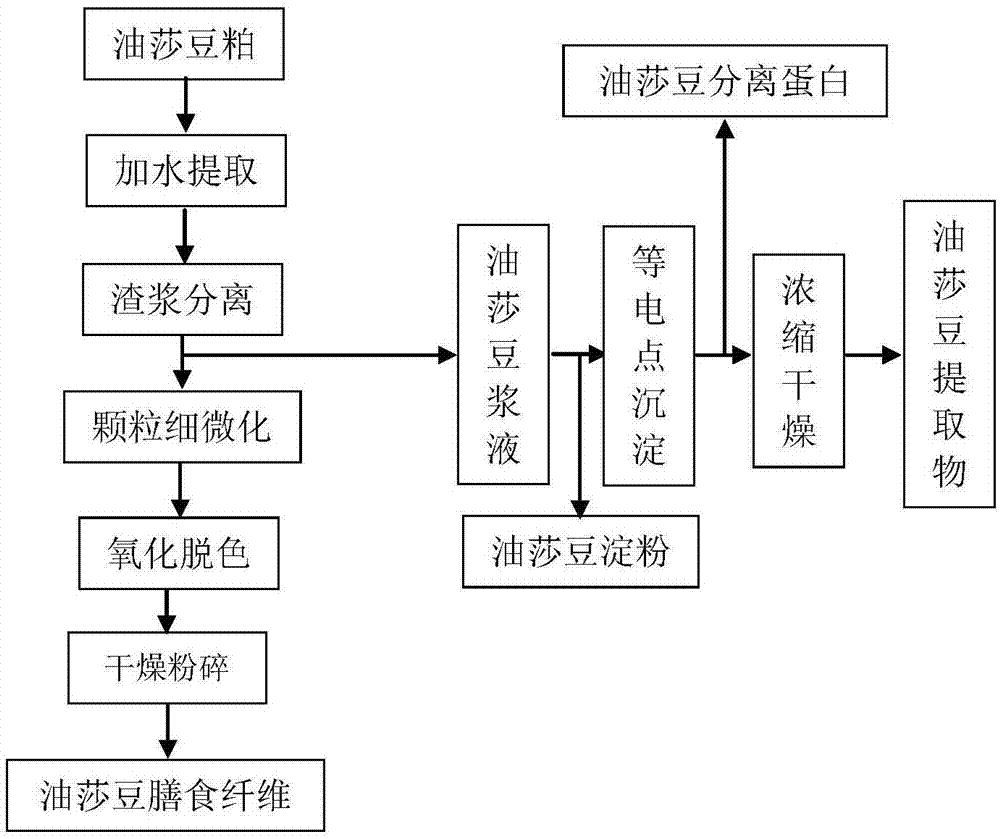

[0042]A method for comprehensively utilizing oily soybean meal, the steps are:

[0043] (1) Crushing and sifting: extract the oily soybean meal, pulverize it with a stainless steel pulverizer and pass through a 20-mesh standard sieve to obtain the oily soybean meal powder for later use.

[0044] (2) Soaking in water and protein extraction: Take 20kg of oily soybean meal powder, add water 5 times its mass, adjust the temperature of the mixture to 25°C, and stir for 1 hour to make the oily soybean meal powder fully absorb water and expand; under stirring, The pH of the mixed material is adjusted to 8.4, 8.5 or 8.6 with a 5% sodium hydroxide solution by mass percentage, and the stirring is continued for 1.5 hours to dissolve the protein of the oily soybean meal, and the water-extracted mixed material of the oily soybean meal after the protein is dissolved is obtained. The stirring speed of this step is controlled to be 115 rpm.

[0045] (3) Separation of pulp and residue: under ...

Embodiment 2

[0052] A method for comprehensively utilizing oily soybean meal, the steps are:

[0053] (1) Crushing and sifting: extract the oily soybean meal, pulverize it with a stainless steel pulverizer and pass through a 40-mesh standard sieve to obtain the oily soybean meal powder for later use.

[0054] (2) Soaking in water and protein extraction: take 523 kg of oily soybean meal powder, add water 6 times its mass, and stir at room temperature for 1 hour to fully absorb water and swell the oily soybean meal powder; 5% potassium hydroxide solution is used to adjust the pH of the mixed material to 8.9 or 9.0 or 9.1, and the stirring is continued for 1 hour to dissolve the oily bean protein to obtain the water-extracted mixed material of oily soybean meal after the protein is dissolved. The stirring speed of this step is controlled to be 125 rpm.

[0055] (3) Separation of pulp and residue: under the condition of continuous stirring, the oily soybean meal water extraction mixture obtai...

Embodiment 3

[0062] A method for comprehensively utilizing oily soybean meal, the steps are:

[0063] (1) Grinding and sieving: take oily bean leaching meal, pulverize it with a stainless steel pulverizer and sieve through a 20-mesh standard sieve to obtain oily bean meal powder for later use.

[0064](2) Soaking in water and protein extraction: Take 912 kg of oily soybean meal powder, add water 8 times its mass, and stir for 2 hours to make the oily soybean meal powder fully absorb water and swell; The sodium solution adjusts the pH of the mixed material to 7.9 or 8.0 or 8.1, and continues to stir for 2.5 hours to dissolve the protein of the oily soybean, and obtain the mixed material of the water-extracted oily soybean meal after the protein is dissolved. The stirring speed of this step is controlled to be 135 rpm.

[0065] (3) Separation of pulp and residue: under the condition of constant stirring, add the oily soybean meal water extraction mixture obtained in step (2) into the starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com