High handling capacity nitrogen purifying device and method for ferrous metallurgy industry

A technology for iron and steel metallurgy and purification equipment, which is used in the field of protective gas for production in iron and steel metallurgy industry, and large-capacity nitrogen purification equipment in iron and steel metallurgy industry. Quality stability and other issues, to achieve the effect of saving regeneration gas, high regeneration temperature, and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

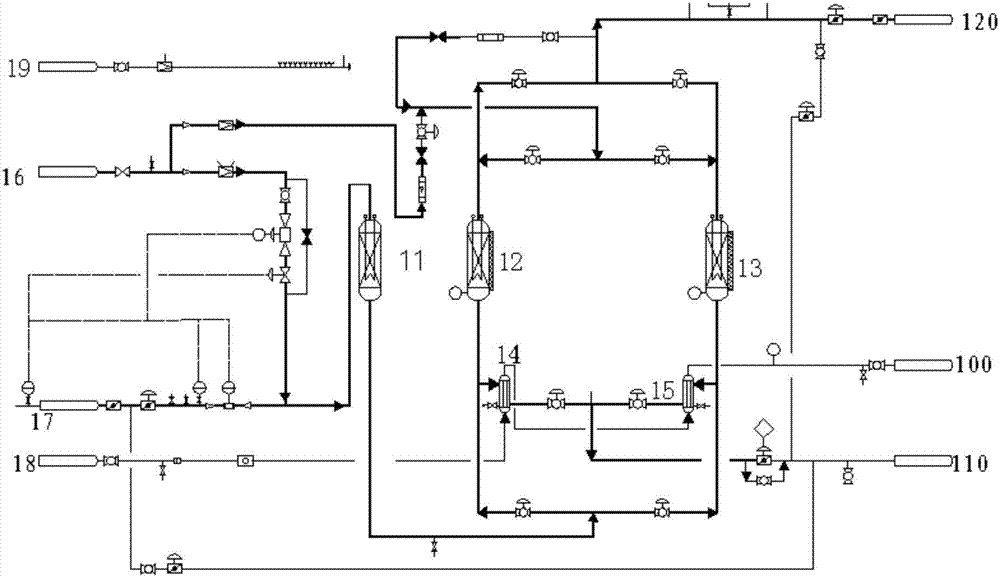

[0053] Embodiment 1 two tower adsorption

[0054] Such as figure 1 As shown, the raw material nitrogen enters the catalytic deoxygenator 11 after being detected by the raw material gas inlet 17, the inlet valve, the flow meter and the inlet gas analyzer. Under normal temperature conditions, the oxygen is converted into water through the catalytic action of the catalyst, and then enters the deoxidation dryer A12 through the outlet valve, and the residual O is removed under the action of the deoxidizer. 2 、H 2 O.CO 2 and other impurities, when the deoxygenation dryer A12 works as a reactor, the deoxygenation dryer B13 is regenerated. Each deoxygenation adsorber goes through the same procedure of steps. Controlling the hydrogenation process can ensure that the added hydrogen can meet the deoxidation requirements, and hydrogenation is not excessive.

[0055] Calculation of hydrogenation amount: through the detected raw material gas flow rate and raw material oxygen content, t...

Embodiment 2 3

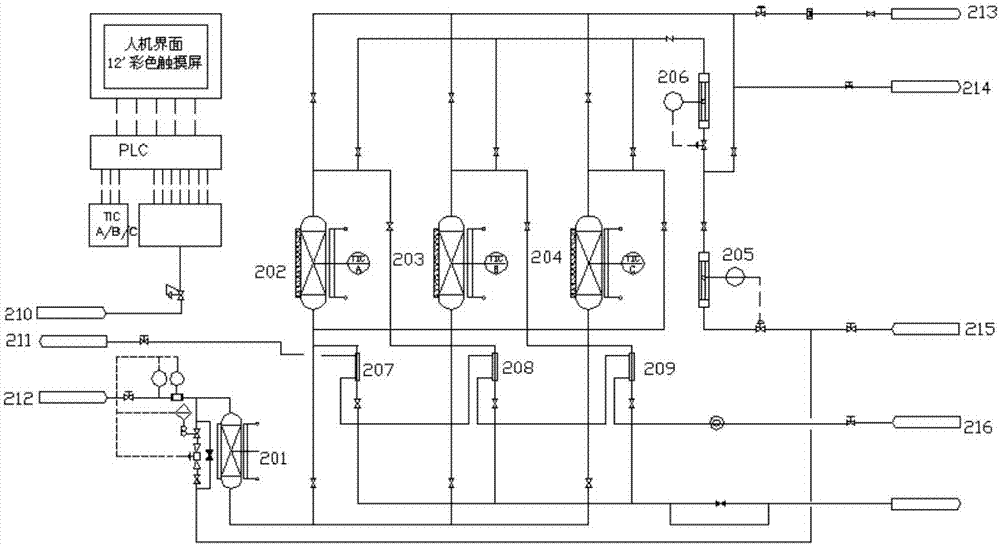

[0109] Example 2 Three-tower adsorption

[0110] Such as figure 2 As shown, the raw material nitrogen enters the catalytic deoxygenator 201 after being detected by the raw material gas inlet 212, the inlet valve, the flow meter and the inlet gas analyzer. Under normal temperature conditions, through the catalytic action of the catalyst, the oxygen is converted into water and removed, and then through the gas-water separator, through the outlet valve, it enters the deoxygenation dryer A202 and the deoxygenation dryer B203 to remove the residual Oxygen under the action of the deoxidizer. 2 、H 2 O.CO 2 and other impurities, when the deoxygenation dryer A202 and the deoxygenation dryer B203 in series work as reactors, the deoxygenation dryer C204 is regenerated. Each deoxygenation adsorber goes through the same procedure of steps. Three deoxidizing dryers work and regenerate alternately to realize the continuous purification of raw nitrogen. In order to ensure the continuous...

Embodiment 3 4

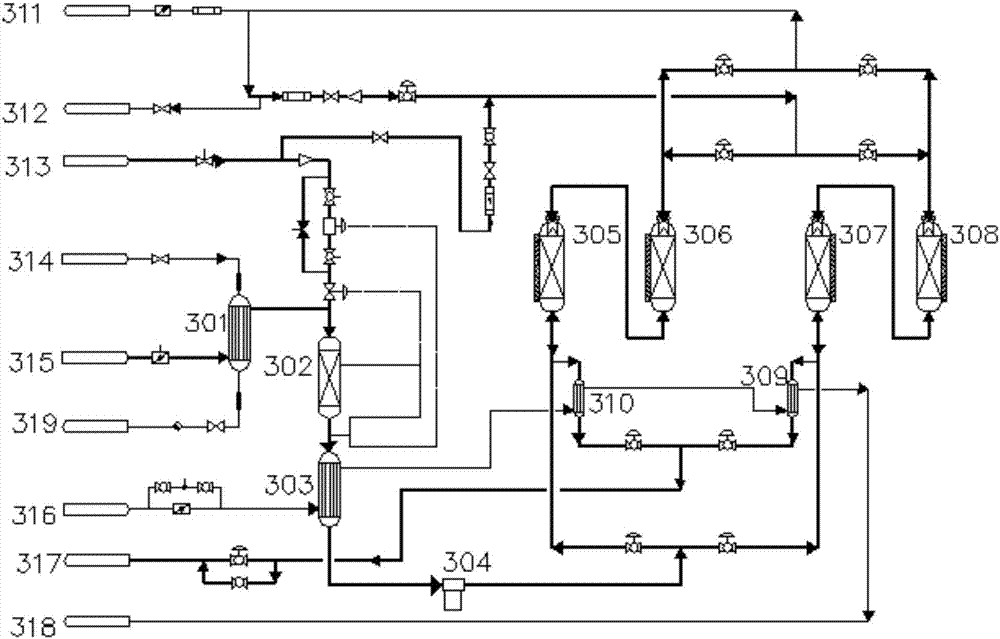

[0115] Example 3 Four-tower adsorption

[0116] Such as image 3 As shown, the raw material nitrogen enters the catalytic deoxygenator 302 after being detected by the raw material gas inlet 315, the inlet valve, the flow meter and the inlet gas analyzer. Under normal temperature conditions, the oxygen is converted into water through the catalytic action of the catalyst to remove, and then through the gas-water separator, through the outlet valve, it enters the deoxygenation dryer A305 and the deoxygenation dryer B306 to remove the residual Oxygen under the action of the deoxidizer. 2 、H 2 O.CO 2 and other impurities, when the two-tower deoxygenation dryer A305 and deoxygenation dryer B306 work as reactors in series, the deoxygenation dryer C307 and deoxygenation dryer D308 are regenerated. Each deoxygenation adsorber goes through the same procedure of steps. The four deoxidizing dryers are divided into two groups, and the two groups work and regenerate alternately to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com