Method for preparing WO3 electrochromic film by potentiodynamic electrochemical deposition

An electrochromic and electrochemical technology, applied in coatings and other directions, can solve the problems of complex hydrothermal process, inability to prepare large-area thin films, and expensive magnetron sputtering equipment, and achieve good electrochromic and optical properties. High performance, high repeatability, uniform film formation and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

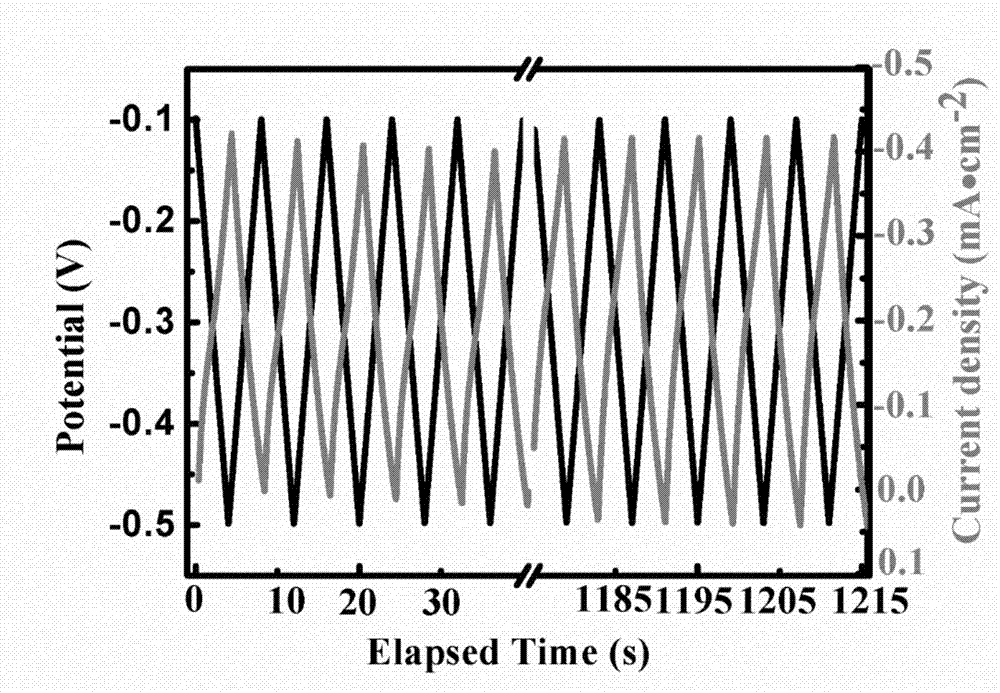

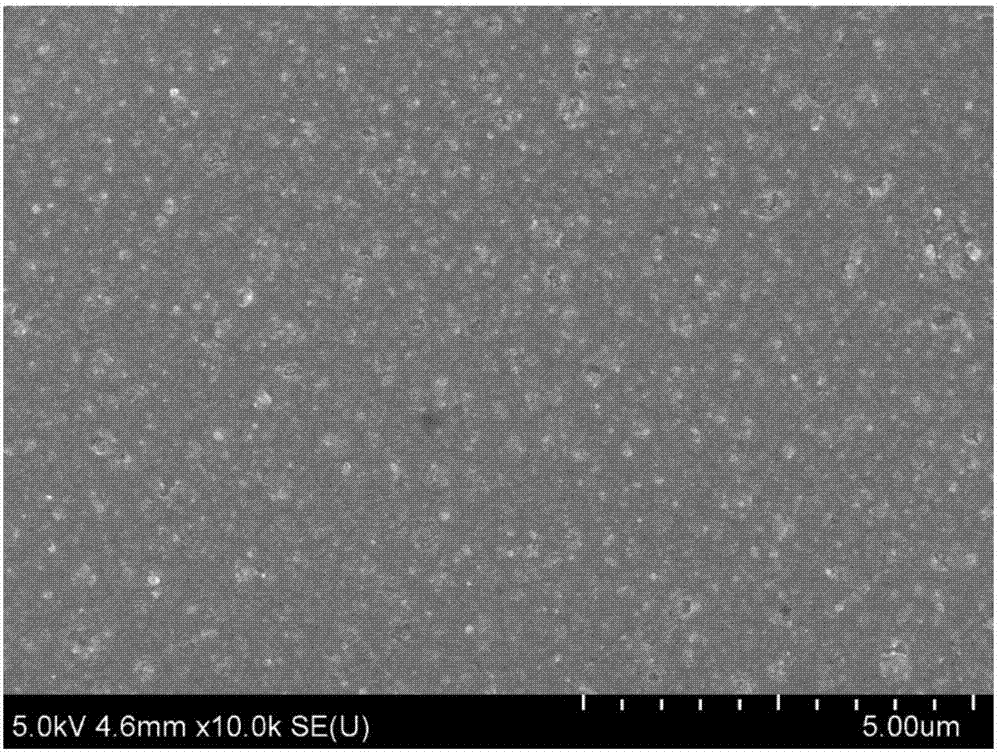

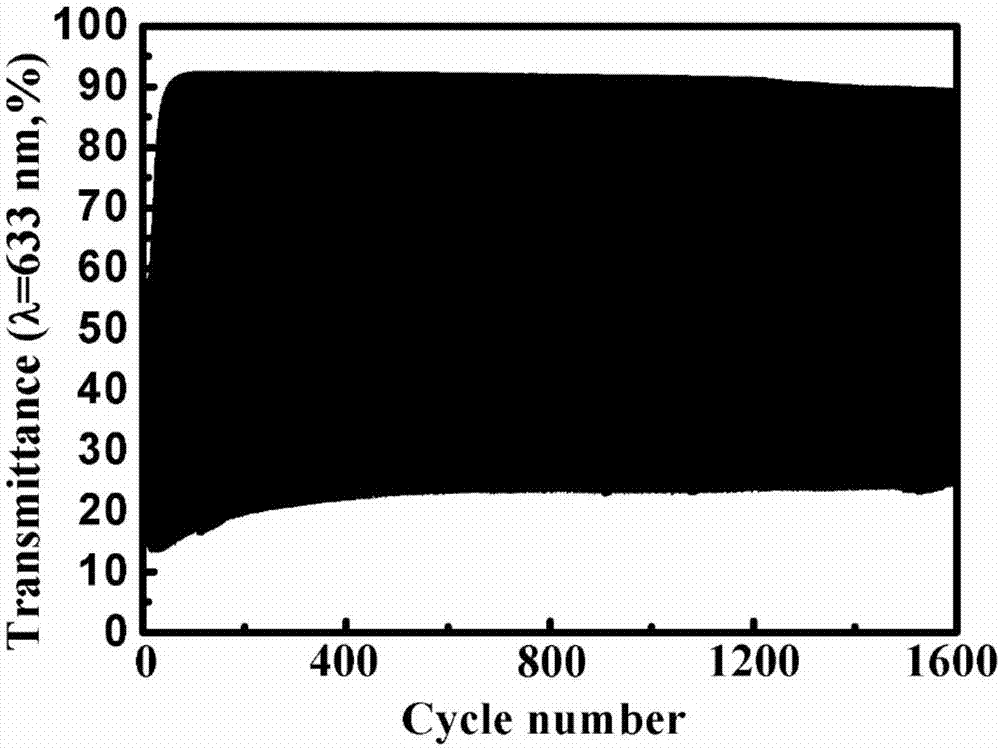

[0021] In the following examples, the Princeton Versa STAT 4 electrochemical workstation was used to carry out potentiodynamic electrochemical deposition of thin films and test the electrochemical properties of the thin films; Hitachi S-4800 field emission electron microscope was used to measure the microscopic morphology of the prepared thin films; SHIMADZU UV-3600 was used The optical transmittance of the prepared films was measured by UV-vis spectrophotometer.

[0022] 1. Add 10g of tungsten powder into 40ml of hydrogen peroxide one by one until the tungsten powder is completely dissolved. This process is an exothermic reaction. Then add 60ml of ethanol and 20ml of acetic acid to dilute evenly. The function of ethanol is to dilute the solution, and the function of acetic acid is to adjust the solution. pH, after fully reacting, a milky white solution was obtained, and finally centrifuged with a high-speed centrifuge for 20min at a speed of 12000r / min to finally obtain a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com