Wheat straw fermented concrete block and preparation method thereof

A technology of concrete blocks and wheat straw, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of toxicity, soil erosion, etc., and achieve the effect of light weight, good nutrient conditions, nutrition and mechanical strength coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

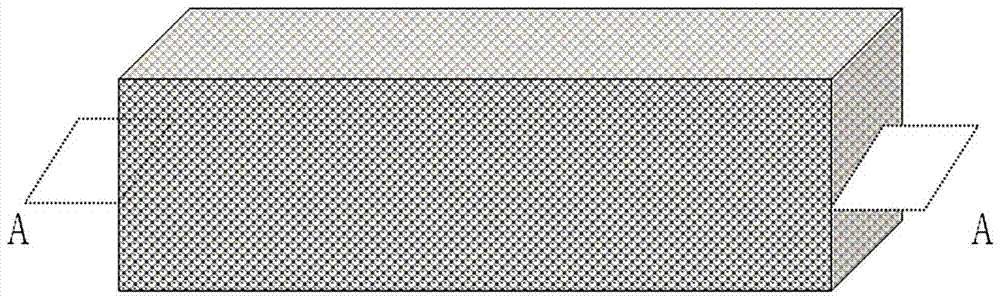

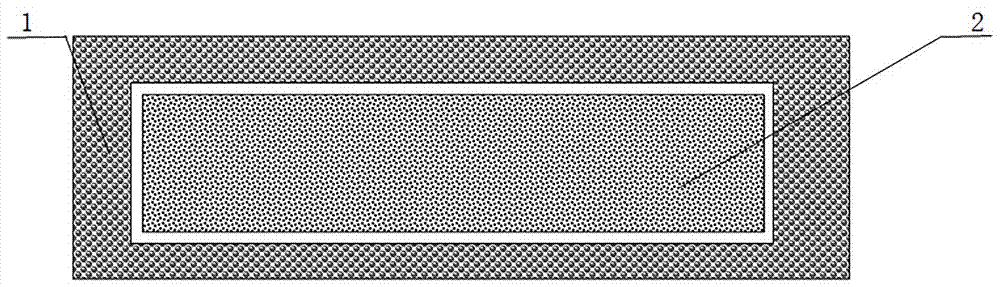

[0044] Such as Figure 1~2 As shown, a wheat straw fermented concrete block in this embodiment is composed of a hollow porous concrete block skeleton and a straw fermentation module. The hollow porous concrete block skeleton 1 is provided with a groove in the middle, and the straw fermentation module 2 Set in the groove of the hollow porous concrete block skeleton 1, the hollow porous concrete block skeleton 1 has a length of 390 mm, a width of 190 mm, and a height of 190 mm; the hollow hollow concrete block skeleton 1 has a length of 320 mm and a width of 120 mm, The height is 120mm; the straw fermentation module 2 is 316mm long, 116mm wide, and 116mm high.

[0045] The preparation method of the wheat straw fermented concrete block includes the following steps:

[0046] 1) Preparation of hollow porous concrete block skeleton:

[0047] Mix ratio 1: Portland cement 200kg / m 3 , Gravel 1400kg / m 3 , Water reducing agent 1kg / m 3 , The water-cement ratio is 0.2, and the particle size of ...

Embodiment 2

[0068] The wheat straw fermented concrete block in this embodiment has the same structure as the wheat straw fermented concrete block in Example 1.

[0069] The preparation process is as follows:

[0070] 1) Preparation of hollow porous concrete block skeleton:

[0071] Mix ratio 1: Portland cement 220kg / m 3 , Gravel 1600kg / m 3 , Water reducing agent 1.2kg / m 3 , The water-cement ratio is 0.25, and the particle size of the crushed stone is 10-15mm;

[0072] Mix ratio 2: Portland cement 220kg / m 3 , Fine sand 310kg / m 3 , Water reducing agent 1.2kg / m 3 , Water cement ratio 0.28;

[0073] Mix the raw materials in mix ratio 1 and mix ratio 2 with a mixer to prepare concrete slurry. The slurry made in mix ratio 1 is poured into the lower layer of the hollow porous concrete block skeleton mold, and the slurry made in mix ratio 2 Pour into the upper layer of the mold, demould within 2 days and put it indoors, natural curing for 17 days;

[0074] 2) Preparation of straw fermentation module:

[007...

Embodiment 3

[0091] The wheat straw fermented concrete block in this embodiment has the same structure as the wheat straw fermented concrete block in Example 1.

[0092] The preparation process is as follows:

[0093] 1) Preparation of hollow porous concrete block skeleton:

[0094] Mix ratio 1: Portland cement 250kg / m 3 , Gravel 1800kg / m 3 , Water reducing agent 1.5kg / m 3 , The water-cement ratio is 0.3, and the particle size of the crushed stone is 10-15mm;

[0095] Mix ratio 2: Portland cement 270kg / m 3 , Fine sand 320kg / m 3 , Water reducing agent 1.4kg / m 3 , Water cement ratio 0.3;

[0096] Mix the raw materials in mix ratio 1 and mix ratio 2 with a mixer to prepare concrete slurry. The slurry made in mix ratio 1 is poured into the lower layer of the hollow porous concrete block skeleton mold, and the slurry made in mix ratio 2 Pour into the upper layer of the mold, demold in 3 days and place it indoors, and maintain it naturally for 20 days;

[0097] 2) Preparation of straw fermentation module:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com