Method for preparing organic fertilizer from lincomycin fungi residues

A lincomycin and organic fertilizer technology, which is applied in the directions of organic fertilizers, inorganic fertilizers, fertilizers made from biological wastes, etc., to achieve the effect of strong bactericidal ability, mild treatment conditions, and realization of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: a kind of method of utilizing lincomycin slag to produce organic fertilizer of the present embodiment, carries out according to the following steps:

[0027] 1. Collect fresh lincomycin residue, add deionized water to adjust the moisture content to 85-90%, and obtain the residue to be treated;

[0028] 2. Use a NaOH solution with a concentration of 5M to adjust the pH of the bacteria residue to 7-8;

[0029] 3. Add potassium persulfate and zinc acetate to the lincomycin residue after pH adjustment in step 2, and mix well; wherein, the molar ratio of lincomycin to persulfate and zinc is 1:22-26 : 0.8;

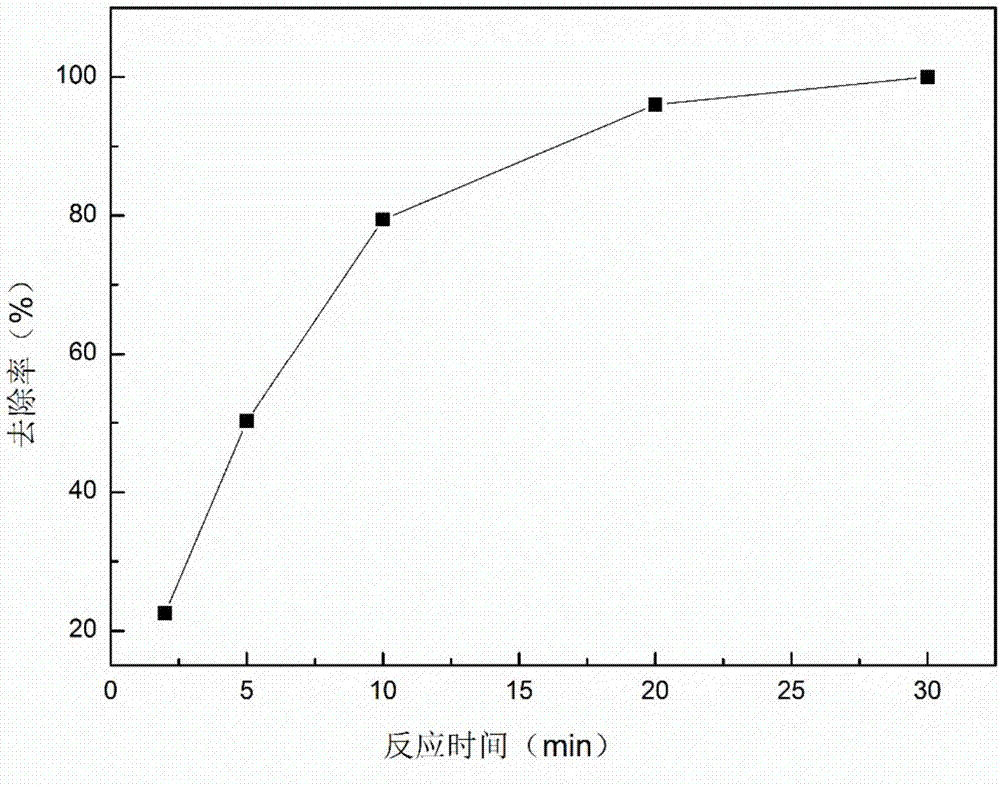

[0030] 4. Put the fungus residue treated in step 3 in a water bath at 80°C, and oxidize it for 0.3-1.0 hours;

[0031] 5. Cool the lincomycin slag after the reaction to room temperature, centrifuge it for 20 minutes at a rotational speed of 4000-8000r / min, dry and granulate the lincomycin residue to make organic fertilizer, that is, complete the...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that fresh lincomycin residues are collected and deionized water is added to adjust the water content to 85-90% to obtain the residues to be treated. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the pH in step 2 is 7.5. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com