Disease-preventing planting base fertilizer for psidium guajava and preparation method of disease-preventing planting base fertilizer

A guava and planting-based technology, which is applied to the preparation of organic fertilizers, fertilizers made from biological wastes, nitrogen fertilizers, etc., can solve the problems of guava nutrient deficiency, low fruit yield, soil damage, etc., and improve the survival rate. , good taste, disease prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A base fertilizer for planting guava for disease prevention, wherein the base fertilizer is fermented from the following raw materials in parts by weight: 30 parts of guava rotten branches, 20 parts of rice straw, 10 parts of broad bean straw, 10 parts of camellia oleifera meal, and 10 parts of distiller's grains , 20 parts of chicken manure, 10 parts of human excrement, 0.10 part of diethylaminoethanol hexanoate, 3 parts of plant extract, 0.014 part of putrefaction agent;

[0023] Wherein, the rotting agent is formed by mixing sodium fulvic acid, phosphate rock powder, potassium chloride, magnesium nitrate, quicklime, and carbonamide in a weight ratio of 2:1:1:1:1:4;

[0024] The preparation method of the plant extract is as follows: collect 1 part of arborvitae leaves, 4 parts of Daphne genkwa, 1 part of skeletal root, and 2 parts of brocade lanterns according to parts by weight, clean the above-mentioned raw materials after removing impurities, and then remove the imp...

Embodiment 2

[0030] A base fertilizer for disease prevention planting of guava, wherein the base fertilizer is fermented from the following raw materials by weight: 35 parts of guava rotten branches, 25 parts of rice straw, 15 parts of broad bean straw, 12 parts of camellia oleifera meal, and 15 parts of distiller's grains , 25 parts of chicken manure, 15 parts of human feces, 0.12 parts of diethylaminoethanol hexanoate, 5 parts of plant extracts, 0.016 parts of putrefaction agents;

[0031] Wherein, the rotting agent is formed by mixing sodium fulvic acid, phosphate rock powder, potassium chloride, magnesium nitrate, quicklime, and carbonamide in a weight ratio of 3:2:2:2:1:6;

[0032] The preparation method of the plant extractant is as follows: collect 2 parts of orientalis leaves, 6 parts of Daphne genkwa, 3 parts of Speranthus fragrans, and 4 parts of brocade lanterns according to parts by weight, clean the above-mentioned raw materials after removing impurities, and then remove the im...

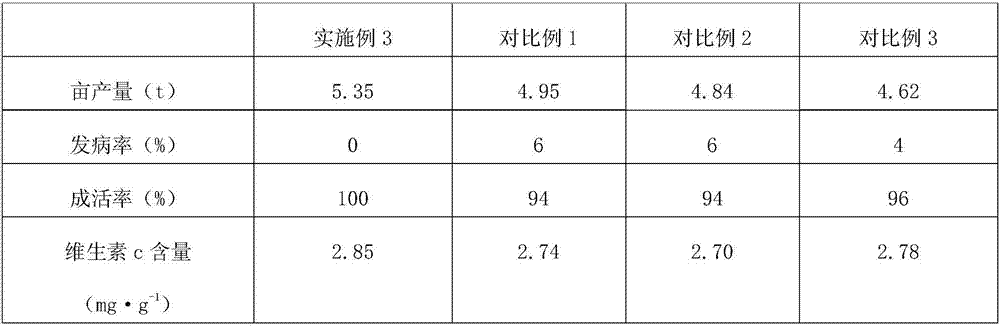

Embodiment 3

[0038] A base fertilizer for disease prevention planting of guava, wherein the base fertilizer is fermented from the following raw materials in parts by weight: 33 parts of guava rotten branches, 24 parts of rice straw, 13 parts of broad bean straw, 11 parts of camellia oleifera meal, 14 parts of distiller's grains , 24 parts of chicken manure, 12 parts of human excrement, 0.11 part of diethylaminoethanol hexanoate, 4 parts of plant extracts, 0.015 parts of putrefaction agent;

[0039] Wherein, the rotting agent is formed by mixing sodium fulvic acid, phosphate rock powder, potassium chloride, magnesium nitrate, quicklime, and carbonamide in a weight ratio of 2.5:1.5:1.4:1.3:1:5;

[0040] The preparation method of the plant extractant is as follows: collect 1.6 parts of orientalis leaves, 5 parts of Daphne genkwa, 2 parts of Speranthus fragrans, and 3 parts of brocade lanterns according to parts by weight, clean the above-mentioned raw materials after removing impurities, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com