Preparation method of water retaining agent for planting edible mushrooms

A technology of water-retaining agent and edible fungus, which is applied in the direction of chemical instruments and methods, applications, organic fertilizers, etc. It can solve the problems of sudden changes in water-retaining performance, root rot, and increased labor input costs, so as to improve production and quality, and excellent water retention Performance, the effect of reducing the frequency of water application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

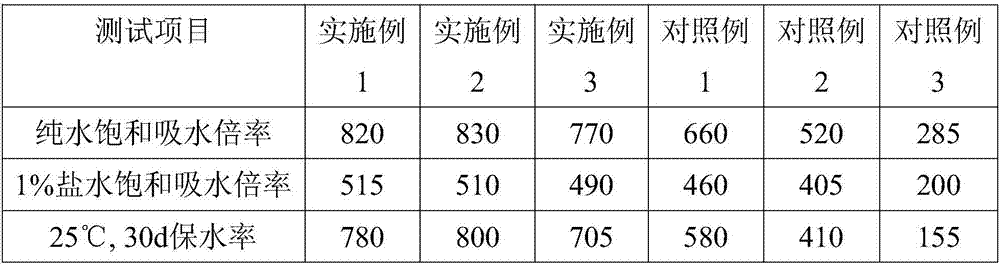

Examples

Embodiment 1

[0019] (1) Base material preparation: Dry the wheat straw under natural conditions until the water content is lower than 5%, then transfer the wheat straw to an environment of 70-80°C to dry until the water content is lower than 0.5%, and use a pulverizer to make the particle size 2-3mm coarse powder, and then hot-press the straw coarse powder at a temperature of 115-125°C and a pressure of 0.5 MPa for 10 minutes, and use a pulverizer to make the obtained straw cake into a fine powder with a particle size of less than 0.5 mm to obtain the base material;

[0020] (2) Processing of auxiliary materials: Heat 5kg of quartz sand, 3kg of hydroxypropyl starch ether, 0.5kg of hydroxypropylmethylcellulose / polyaspartic acid, 1kg of activated clay, and 0.2kg of zeolite powder to 115-125°C for heat preservation and mixing 10min, after natural cooling to room temperature, the excipients were obtained;

[0021] (3) Preparation of water-retaining agent: Mix 10kg of base material and 0.5kg of...

Embodiment 2

[0025] (1) Base material preparation: Dry the wheat straw under natural conditions until the water content is lower than 5%, then transfer the wheat straw to an environment of 70-80°C to dry until the water content is lower than 0.5%, and use a pulverizer to make the particle size 2-3mm coarse powder, then hot-press the straw coarse powder at a temperature of 115-125°C and a pressure of 0.5 MPa for 15 minutes, and use a pulverizer to make the obtained straw cake into a fine powder with a particle size of less than 0.5 mm to obtain the base material;

[0026] (2) Processing of auxiliary materials: Heat 5kg of quartz sand, 5kg of hydroxypropyl starch ether, 1kg of hydroxypropylmethylcellulose / polyaspartic acid, 0.5kg of activated clay, and 0.3kg of zeolite powder to 115-125°C for heat preservation and mixing After 15 minutes, naturally cool to room temperature to obtain the excipients;

[0027] (3) Preparation of water-retaining agent: Mix 15kg base material and 1kg auxiliary ma...

Embodiment 3

[0031] (1) Base material preparation: Dry the wheat straw under natural conditions until the water content is lower than 5%, then transfer the wheat straw to an environment of 70-80°C to dry until the water content is lower than 0.5%, and use a pulverizer to make the particle size 2-3mm coarse powder, then hot-press the straw coarse powder at a temperature of 115-125°C and a pressure of 0.5 MPa for 15 minutes, and use a pulverizer to make the obtained straw cake into a fine powder with a particle size of less than 0.5 mm to obtain the base material;

[0032] (2) Processing of auxiliary materials: Heat 5kg of quartz sand, 5kg of hydroxypropyl starch ether, 1kg of hydroxypropylmethylcellulose / polyaspartic acid, 0.5kg of activated clay, and 0.3kg of zeolite powder to 115-125°C for heat preservation and mixing After 15 minutes, naturally cool to room temperature to obtain the excipients;

[0033] (3) Preparation of water-retaining agent: Mix 15kg base material and 1kg auxiliary ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com