A silica fume modified intumescent flame retardant wood composite coating

A composite coating and intumescent technology, which is applied in polyester coatings, fire-resistant coatings, coatings, etc., can solve the problems of less research on the modification of flame-retardant wood coatings, and achieve strong self-extinguishing properties, high flame-retardant performance, and thermal stability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

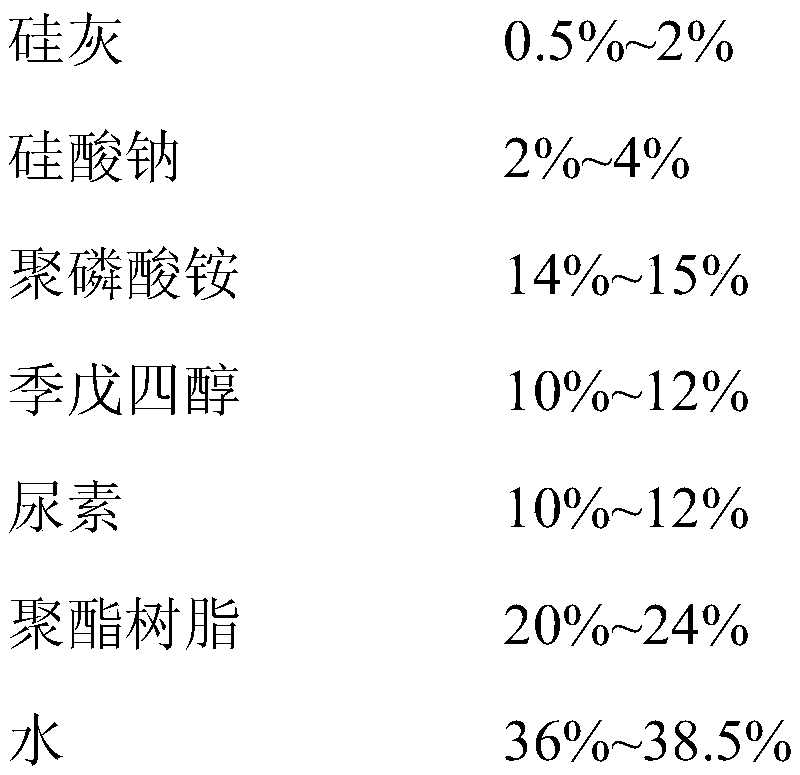

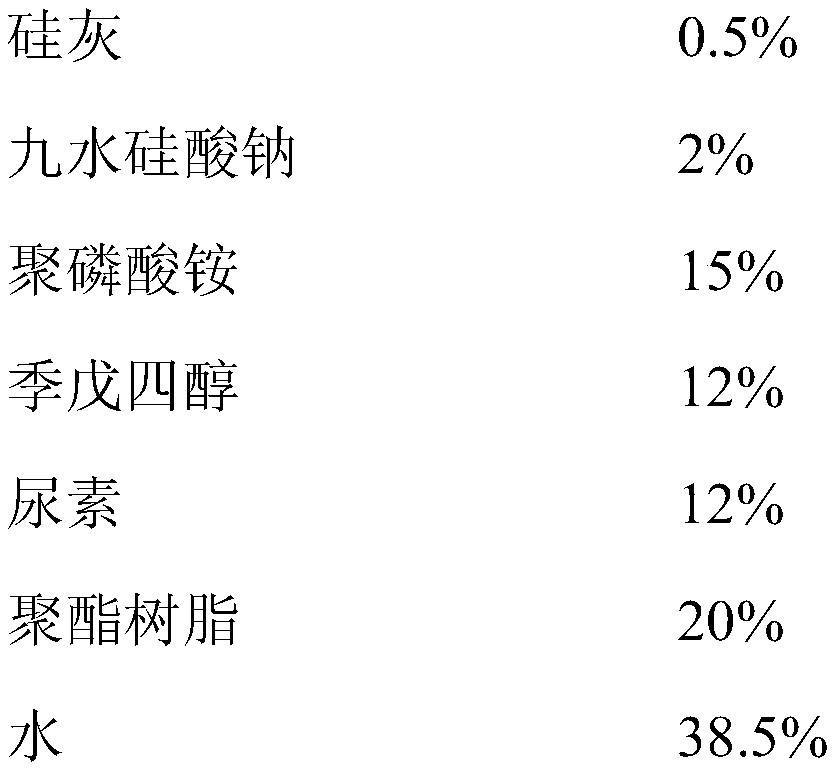

[0024] This embodiment provides a method for preparing a silica fume modified intumescent flame-retardant wood composite coating, which includes the following raw materials:

[0025]

[0026] Its preparation includes the following steps:

[0027] First, prefabricate silica fume-based sol: Dissolve the formulated amount of activator into quantitative water and place it in a magnetic heating stirrer at 60°C for 30 minutes at a stirring speed of 300 r / min. At the same time, add the formulated amount of silica fume to obtain silica fume-based sol; At the same time, fully stir the formula ammonium polyphosphate, pentaerythritol, urea, and polyester resin to form a uniform jelly; then pour the prefabricated silica fume-based sol into the jelly, and add it in about 3 to 5 minutes, at 1000 to 1500r / min Stirring for 10-15min, standing still to get the composite coating.

[0028] The composite coating is coated on the surface of the plywood sample, and its limiting oxygen index (LO...

Embodiment 2

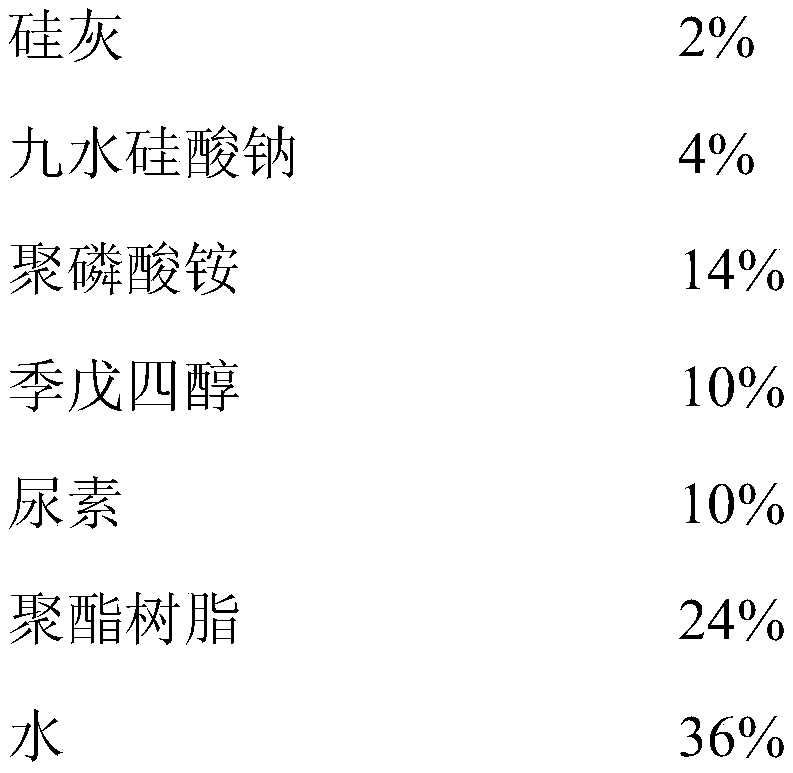

[0031] This embodiment provides a preparation method of silica fume modified intumescent flame-retardant wood composite coating, including the following raw materials:

[0032]

[0033] The preparation steps are the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com