Green silicate fluorescent powder with narrow half peak width and preparation method thereof

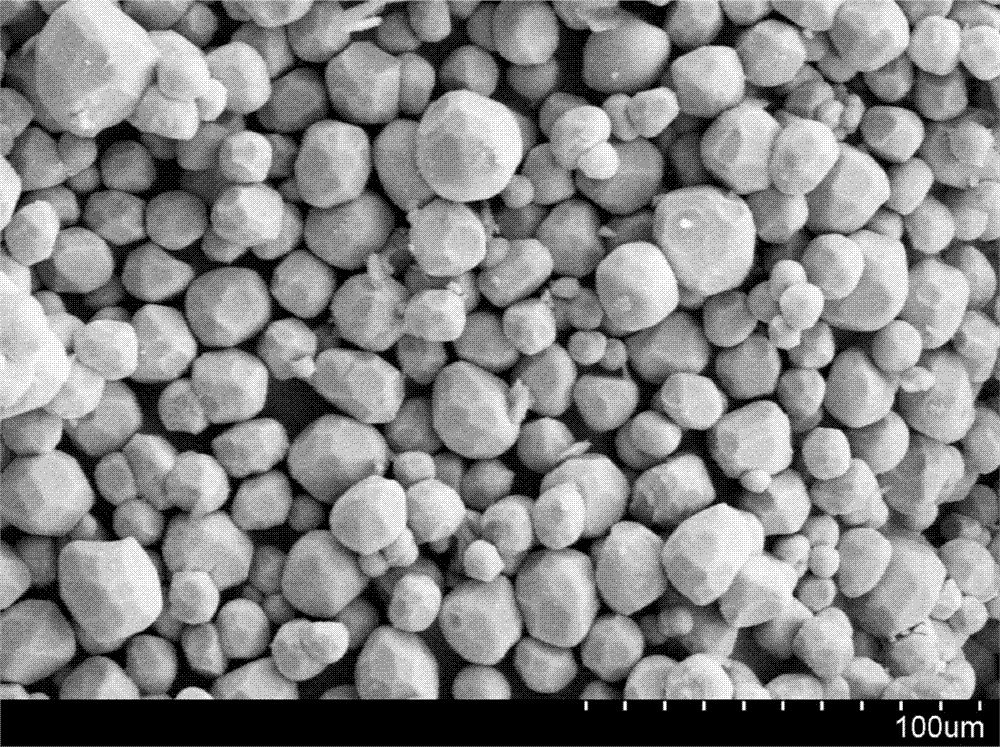

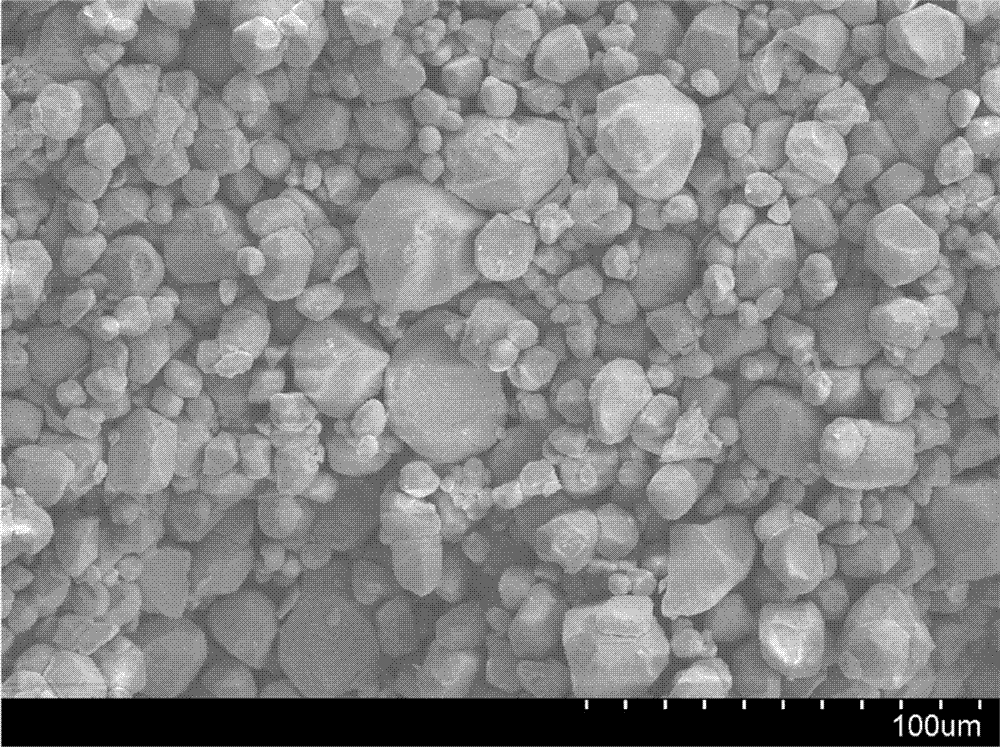

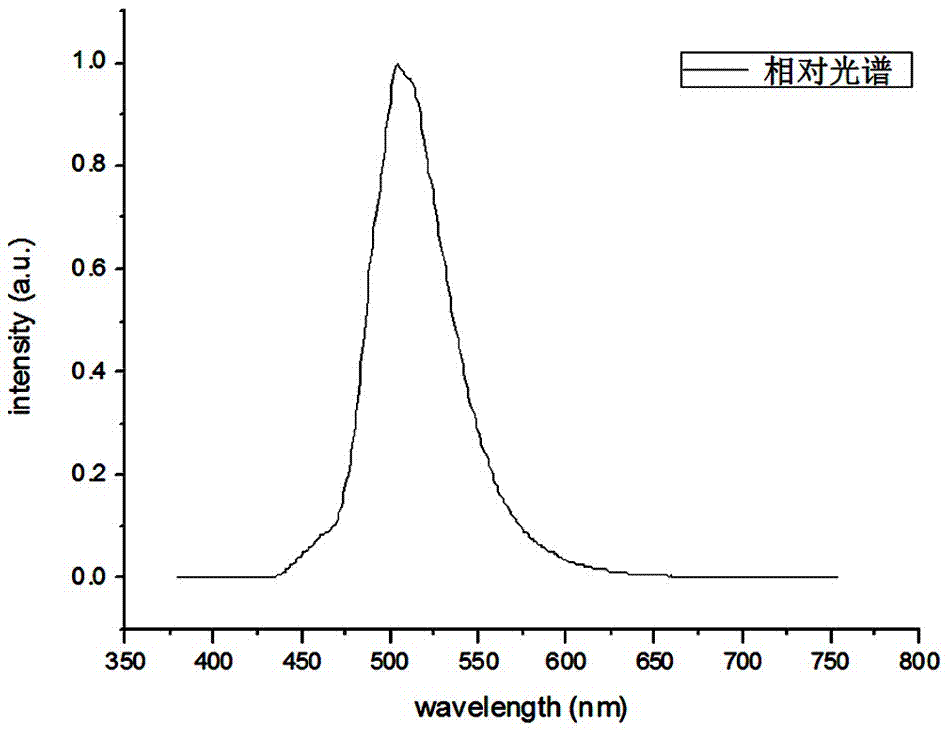

A technology of silicate and half-peak width, which is applied in the field of phosphors and its preparation, can solve the problems of low luminance, poor resistance to humidity and heat, and poor particle size uniformity, and achieve uniform crystallization, reduced lattice distortion, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) According to the general chemical formula Sr 0.1 Ba 1.7 Mg 0.05 Cu 0.05 Si 0.9 Ge 0.1 o 4 : 0.08Mn, the molar ratio of each element in 0.02Eu Weigh 0.1mol of SrCO 3 , 1.7mol of BaCO 3 , 0.05mol of MgO, 0.05mol of CuO, 0.1mol of GeO 2 , 0.9mol of SiO 2 , 0.01mol of Eu 2 o 3 , 0.08mol of MnO 2 and 0.05mol of MgCl 2 and 0.03mol of CaCl 2 , carried out in a glove box with water and oxygen content less than 0.1ppm, put the weighed raw materials into a ziplock bag, and fill the bag with an appropriate amount of N 2 Inert gas, shake irregularly and violently for 20 minutes by hand shaking; continue to pour the hand-mixed raw materials into the mixing bottle in a glove box with water and oxygen content less than 0.1ppm, put the ball milling medium in the bottle, and place it in the mixing bottle. On the feeder, mix the materials for 14 hours to obtain the raw material mixture;

[0033] (2) Take out the phosphor crude product and grind and crush it, pass throu...

Embodiment 2-5

[0036] The process steps for preparing phosphors in Examples 2-5 and Comparative Examples 3 and 4 are the same as in Example 1, except that the reaction temperature in step (2) is changed.

[0037] project

Embodiment 6-9

[0039] The process steps for preparing phosphors in Examples 6-9 and Comparative Examples 5-6 are the same as those in Example 1, only the heat preservation reaction time in step (2) is changed.

[0040] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com