Integrated packaging structure, and process for manufacturing integrated packaging structure

An integrated packaging and process technology, applied in the field of integrated packaging of optoelectronic devices, can solve the problems of degradation coefficient performance, loss fluctuation of pigtail fusion points, and easy polarization cross-coupling, etc., to eliminate differences in thermal expansion coefficients, reduce installation space requirements, and reduce deformation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

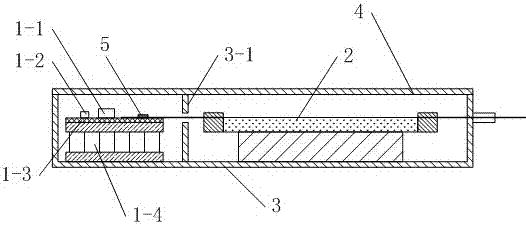

[0025] An integrated packaging structure, the structure of which is: the integrated packaging structure is composed of a semiconductor light emitting device, an optical waveguide modulator chip 2, a housing 3, a cover plate 4, a spacer 5, a connecting optical fiber, and an output pigtail;

[0026] The semiconductor light-emitting device is composed of a semiconductor light-emitting chip 1-1, a thermal diode 1-2, a heat sink 1-3 and a semiconductor refrigerator 1-4; the inner end of the connecting optical fiber and the input of the optical waveguide modulator chip 2 The inner end of the output pigtail is connected to the output end of the optical waveguide modulator chip 2; the housing 3 is provided with a mounting groove, and the middle part of the mounting groove is provided with a partition 3-1, and the partition 3 -1 divides the installation slot into slot A and slot B;

[0027] The semiconductor light emitting device is arranged in groove A; the bottom surface of the semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com