Turf sodding device achieving continuous sodding

A turf and grass laying technology, which is applied in the directions of plant cultivation, lawn growth, and botanical equipment and methods, can solve the problems of single function, single function of the laying machine, poor lawn laying efficiency, etc., and achieve the effect of improving the flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

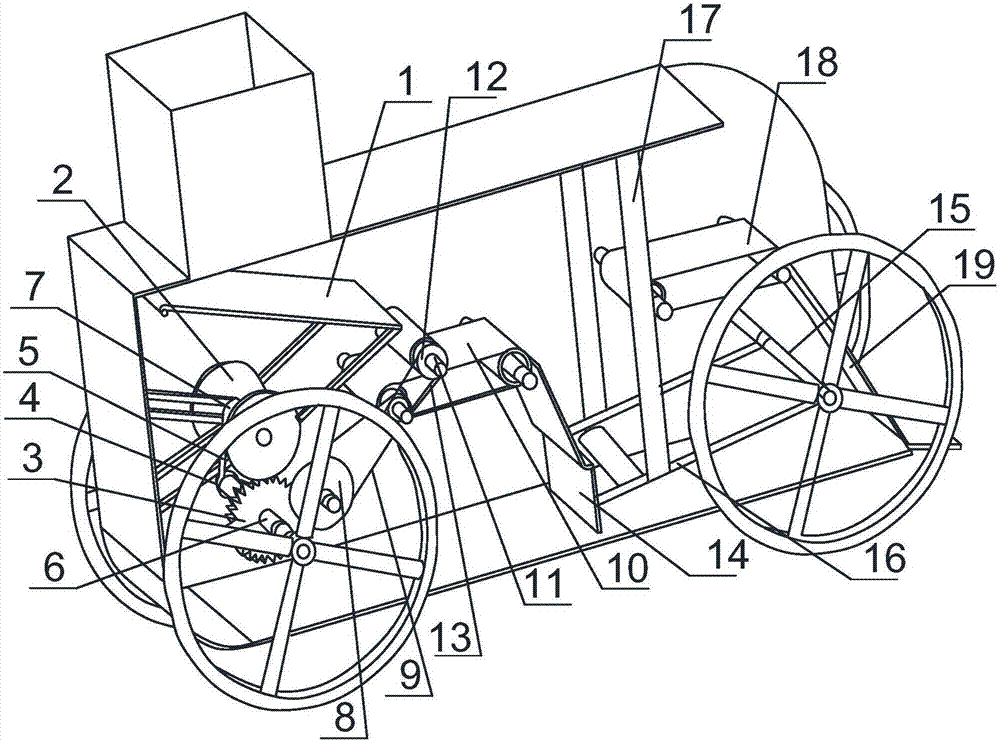

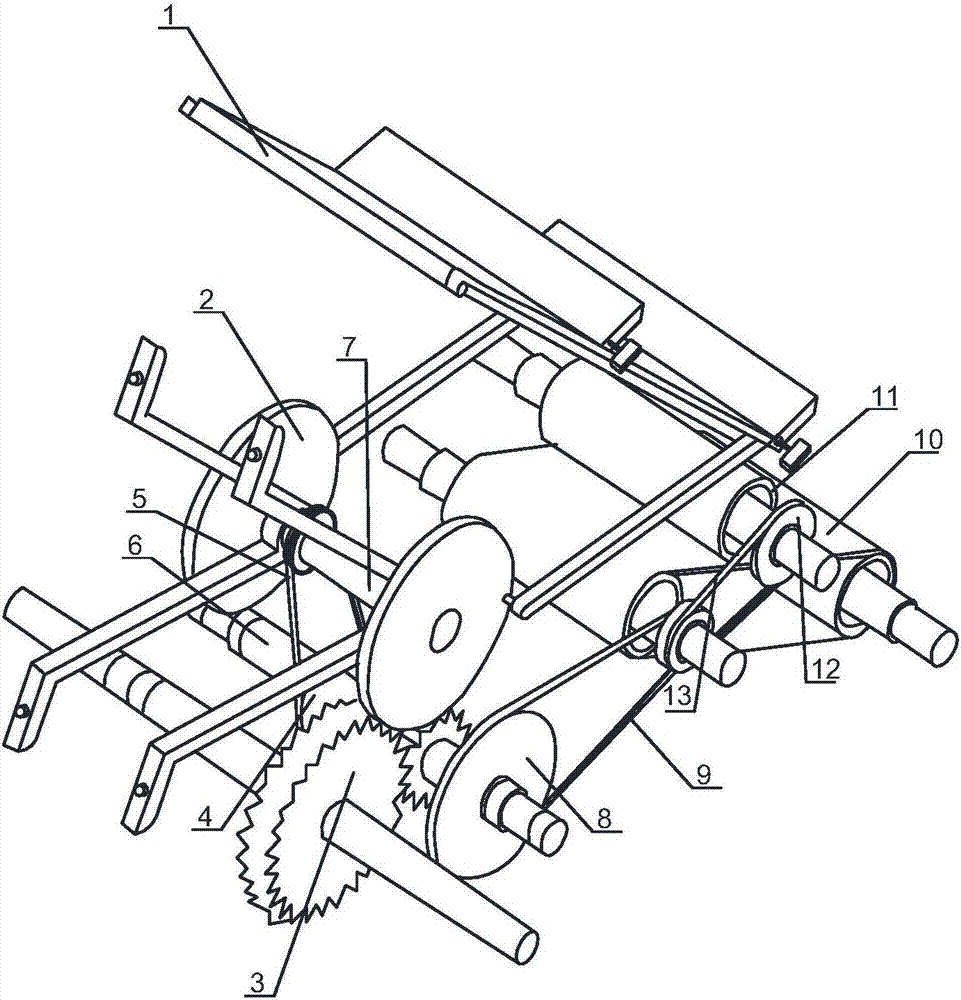

[0025] Such as figure 1 , figure 2As shown, the turf planting device capable of continuous planting of the present invention comprises a vehicle body, an intermittent feeding mechanism installed at the front of the vehicle body and an unfolding mechanism connected to the intermittent feeding mechanism, and a Grass-laying structure, intermittent feeding mechanism, unfolding mechanism, and grass-laying structure are all located inside the vehicle body. The intermittent feeding mechanism includes a slant plate 1 with one end inclined downward, crank set 2, meshing gear set 3, A-type pulley I4, A-type belt I5, the lower surface of the lower end of the swash plate 1 is hinged with the connecting rod of the crank set 2, a gear in the meshing gear set 3 is connected with the A-type pulley I4 through the rotating shaft 6, and the A-type pulley I4 passes through the A-type belt I5 It is connected with the crankshaft 7 of the crankset 2; the unfolding mechanism includes A-type pulley ...

Embodiment 2

[0030] Based on Embodiment 1, the discharge plate 19 includes a long plate connected to one end of the conveyor belt 18, the other end of the long plate is inclined to the rear and downward of the conveyor belt 18, and the lower end of the long plate is connected to a horizontal plate. Form an L-shaped discharge plate with the horizontal plate. The length of the horizontal plate in the L-shaped discharge plate is very short, the turf will not stay on the horizontal plate, and the horizontal plate can play a buffer role for the turf, so that the turf can be laid on the ground slowly, avoiding the turf falling too fast and colliding with the car body Poor speed fit for laying turf quickly and with high quality.

Embodiment 3

[0032] Based on the above embodiment, the soft board 14 includes a plurality of rectangular boards arranged in parallel, and adjacent rectangular boards are connected by springs.

[0033] The spring connection is beneficial to fine-tuning the length of the soft board according to the installation position of the conveyor belt during the rising process, which is convenient to use, and the soft board is flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com