A kind of preparation method of anti-stab composite material

A composite material and a technology for preparation steps, which can be applied in chemical instruments and methods, synthetic resin layered products, and biochemical treatment of enzymes/microorganisms, etc. and other problems, to achieve the effect of improving impact resistance, modifying burst resistance, and improving air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

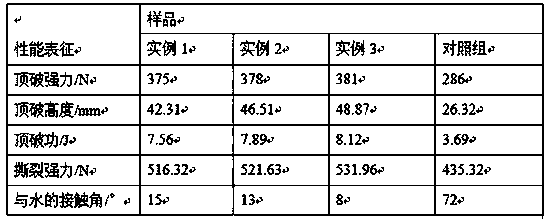

Examples

example 1

[0021] According to the mass ratio of 1:1, the ramie fiber and sisal fiber are mixed to obtain a mixed fiber. According to the mass ratio of 1:10, the mixed fiber and deionized water are stirred and mixed, and the pH is adjusted to 8.0 with a mass fraction of 10% sodium hydroxide solution , Get the mixed solution, and then add xylanase to the mixed solution at 55~60℃ according to the enzyme addition amount 15U / g. After stirring and mixing for 3~5h, the enzyme hydrolysis solution is obtained. The volume ratio is 1: 5. Add 25% solid content silica sol to the enzymolysis solution, stir and mix for 6-8h at 3500~4000r / min, then stop stirring and filter, collect the filter cake and freeze-dry in vacuum, collect the dried modified fiber and put it together Twist the yarn in the fancy twisting machine, collect the mixed fiber thread, place it on the loom for weaving, control the weft density to 150 strands / 10cm, and the warp density to 250 strands / 10cm. After weaving is completed, colle...

example 2

[0023] According to the mass ratio of 1:1, the ramie fiber and sisal fiber are mixed to obtain a mixed fiber. According to the mass ratio of 1:10, the mixed fiber and deionized water are stirred and mixed, and the pH is adjusted to 8.0 with a mass fraction of 10% sodium hydroxide solution , Get the mixed solution, and then add xylanase to the mixed solution at 55~60℃ according to the enzyme addition amount 15U / g. After stirring and mixing for 3~5h, the enzyme hydrolysis solution is obtained. The volume ratio is 1: 5. Add 25% solid content silica sol to the enzymolysis solution, stir and mix for 6-8h at 3500~4000r / min, then stop stirring and filter, collect the filter cake and freeze-dry in vacuum, collect the dried modified fiber and put it together Twist the yarn in the fancy twisting machine, collect the mixed fiber thread, place it on the loom for weaving, control the weft density to 150 strands / 10cm, and the warp density to 250 strands / 10cm. After weaving is completed, colle...

example 3

[0025] According to the mass ratio of 1:1, the ramie fiber and sisal fiber are mixed to obtain a mixed fiber. According to the mass ratio of 1:10, the mixed fiber and deionized water are stirred and mixed, and the pH is adjusted to 8.0 with a mass fraction of 10% sodium hydroxide solution , Get the mixed solution, and then add xylanase to the mixed solution at 55~60℃ according to the enzyme addition amount 15U / g. After stirring and mixing for 3~5h, the enzyme hydrolysis solution is obtained. The volume ratio is 1: 5. Add 25% solid content silica sol to the enzymolysis solution, stir and mix for 6-8h at 3500~4000r / min, then stop stirring and filter, collect the filter cake and freeze-dry in vacuum, collect the dried modified fiber and put it together Twist the yarn in the fancy twisting machine, collect the mixed fiber thread, place it on the loom for weaving, control the weft density to 150 strands / 10cm, and the warp density to 250 strands / 10cm. After weaving is completed, colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com