Ozone full-utilization type sludge reduction reaction system and sludge treatment method

A reaction system and sludge treatment technology, applied in the field of ozone full utilization sludge reduction reaction system and sludge treatment, can solve the problems that are not conducive to large-scale popularization and application, slow sludge oxidation reaction, low ozone utilization efficiency, etc. , to achieve the effect of simple structure, small footprint and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

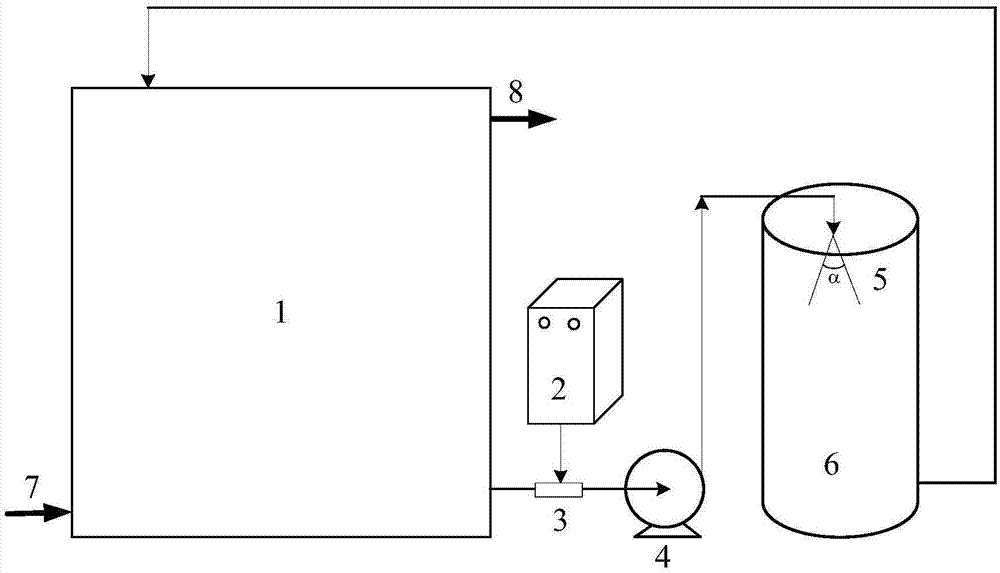

[0036] In this embodiment, sludge reduction is carried out for the low dosage of ozone in the reaction tank 1 .

[0037] The inlet of the ejector 3 is installed on the outlet of the reaction tank 1, and the air inlet of the ejector 3 is connected with the outlet pipe of the 30 g / h ozone generator 2 at the same time. Install the booster pump 4 so that its inlet is connected to the outlet of the ejector 3 . A large downward horn-shaped nozzle 5 is installed on the inside of the mixing tank 6, the angle of the horn is 10 degrees, and the height is 1 / 10 of the height of the mixing tank 6, and the outlet of the booster pump 4 is connected to the inlet of the nozzle 5. A sludge outlet is installed at the bottom of the mixing tank 6 and connected to the reaction tank 1 . The inlet of the sludge to be treated and the sludge outlet 8 after the reduction reaction is completed are installed on the reaction tank 1 .

[0038]The 30L reaction tank 1 was filled with sludge with an MLSS con...

Embodiment 2

[0042] In this embodiment, sludge reduction is performed by increasing the ozone dosage in the reaction tank 1 .

[0043] The inlet of the ejector 3 is installed on the outlet of the reaction tank 1, and the air inlet of the ejector 3 is connected with the outlet pipe of the 25.5g / h ozone generator 2 at the same time. Install the booster pump 4 so that its inlet is connected to the outlet of the ejector 3 . A large mouth downward horn-shaped nozzle 5 is installed on the inside of the mixing tank 6, the angle of the horn is 30 degrees, and the height is 1 / 5 of the height of the mixing tank 6, and the outlet of the booster pump 4 is connected to the inlet of the nozzle 5. A sludge outlet is installed at the bottom of the mixing tank 6 and connected to the reaction tank 1 . The inlet of the sludge to be treated and the sludge outlet 8 after the reduction reaction is completed are installed on the reaction tank 1 .

[0044] The 40L reaction tank 1 was filled with sludge with an ...

Embodiment 3

[0048] In this embodiment, sludge reduction is performed by increasing the ozone dosage in the reaction tank 1 .

[0049] The inlet of the ejector 3 is installed on the outlet of the reaction tank 1, and the air inlet of the ejector 3 is connected with the outlet pipe of the 30 g / h ozone generator 2 at the same time. Install the booster pump 4 so that its inlet is connected to the outlet of the ejector 3 . A large downward horn-shaped nozzle 5 is installed on the inside of the mixing tank 6, the angle of the horn is 20 degrees, and the height is 1 / 8 of the height of the mixing tank 6, and the outlet of the booster pump 4 is connected to the inlet of the nozzle 5. A sludge outlet is installed at the bottom of the mixing tank 6 and connected to the reaction tank 1 . The inlet of the sludge to be treated and the sludge outlet 8 after the reduction reaction is completed are installed on the reaction tank 1 .

[0050] The 40L reaction tank 1 was filled with sludge with an MLSS co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com