Ceramic composition and preparation method thereof

A technology of ceramic composition and parts by weight, applied in the field of ceramic composition and its preparation, can solve problems such as narrowing the application field, and achieve the effects of high flexural strength, low firing shrinkage rate and strong adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

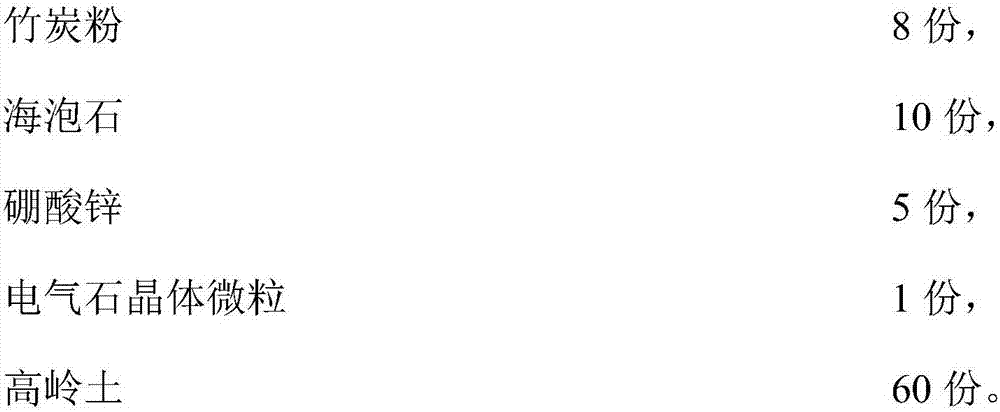

[0038] Configure raw materials by weight percentage:

[0039]

[0040] The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature of 1200° C., and the average particle size of the bamboo charcoal powder is 30 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm 3 , Far-infrared radiation rate of wavelength 4μm-14μm ≥ 90%. The average particle size of tourmaline powder is 50 μm. The particle size of the zinc borate is 100 μm. The sepiolite particle size is 20 μm.

[0041] Its preparation method comprises the following steps:

[0042] (1) Stir and mix bamboo charcoal powder, sepiolite, zinc borate, tourmaline crystal particles and clay in proportion, and grind them into mud;

[0043] (2) Put the mud material in a vacuum mud refiner to refine mud more than twice, and then place it for 24 hours to naturally stale;

[0044] (3) Put the naturally stale ...

Embodiment 2

[0049] Configure raw materials by weight percentage:

[0050]

[0051] The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature of 1250° C., and the average particle size of the bamboo charcoal powder is 100 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm 3 , Far-infrared radiation rate of wavelength 4μm-14μm ≥ 90%. The average particle size of tourmaline powder is 10 μm. The particle size of the zinc borate is 200 μm. The particle size of sepiolite is 0.5 μm.

[0052] Its preparation method comprises the following steps:

[0053] (1) Stir and mix bamboo charcoal powder, sepiolite, zinc borate, tourmaline crystal particles and clay in proportion, and grind them into mud;

[0054] (2) Put the mud material in a vacuum mud refiner to refine the mud more than twice, and then place it for 30 hours to naturally stale;

[0055] (3) Put the natur...

Embodiment 3

[0060] Configure raw materials by weight percentage:

[0061]

[0062] The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature of 1300° C., and the average particle size of the bamboo charcoal powder is 50 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm 3 , Far-infrared radiation rate of wavelength 4μm-14μm ≥ 90%. The average particle size of tourmaline powder is 20 μm. The particle size of the zinc borate is 130 μm. The particle size of sepiolite is 15 μm.

[0063] Its preparation method comprises the following steps:

[0064] (1) Stir and mix bamboo charcoal powder, sepiolite, zinc borate, tourmaline crystal particles and clay in proportion, and grind them into mud;

[0065] (2) Put the mud material in a vacuum mud refiner to refine the mud more than twice, and then place it for 36 hours to naturally stale;

[0066] (3) Put the natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com