Production technology for novel structure wool cloth

A technology of production process and new structure, applied in the field of clothing fabrics, can solve the problems of single pattern of wool fabrics, waste of energy, hard hand feeling, etc., and achieve the effects of satisfying aesthetics and comfort, increasing soft hand feeling, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

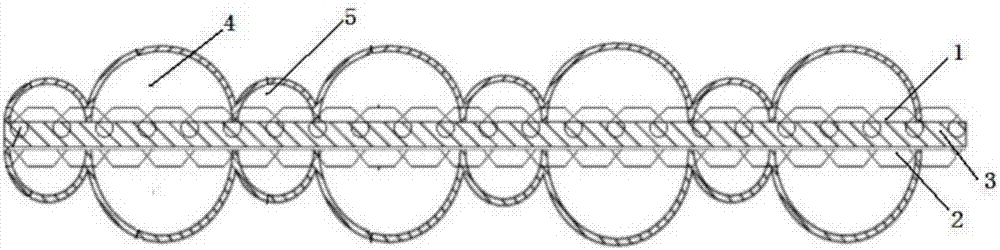

[0014] Example: such as figure 1 Shown: a new type of structure wool cloth production process, including the front coil layer 1, the middle thermal insulation layer 2 and the reverse coil layer 3, the front coil layer is jacquard weave, the reverse coil layer is plain weave, and the middle thermal insulation layer is thermal insulation Layers, the front stitch layer and the back stitch layer form alternating large gaps 4 and small gaps 5 by interweaving stitches along the wales of partial stitches in the transverse direction of the fabric. The front coil layer and the back coil layer are wool or wool blended yarn; the middle thermal layer is 2-4 150D coarse-count nylon yarns.

[0015] The front loop layer of the wool fabric is a jacquard weave, and the reverse loop layer is a plain weave, which effectively improves the texture of the wool surface.

[0016] The efficiency of the material on the machine ensures good quality. At the same time, the fabric uses the organizational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com