Intaglio fine casing pressing wallpaper slurry and preparation method thereof

A kind of gravure and paper pulp technology, applied in the field of gravure fine sleeve press wallpaper slurry and its production method, can solve the problems that the surface of the wallpaper is not smooth enough, the wallpaper is easy to stick together, and affects the packaging and transportation, so as to improve the wear resistance and material quality. Effects of smooth surface, improved strength and elongation, and excellent pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

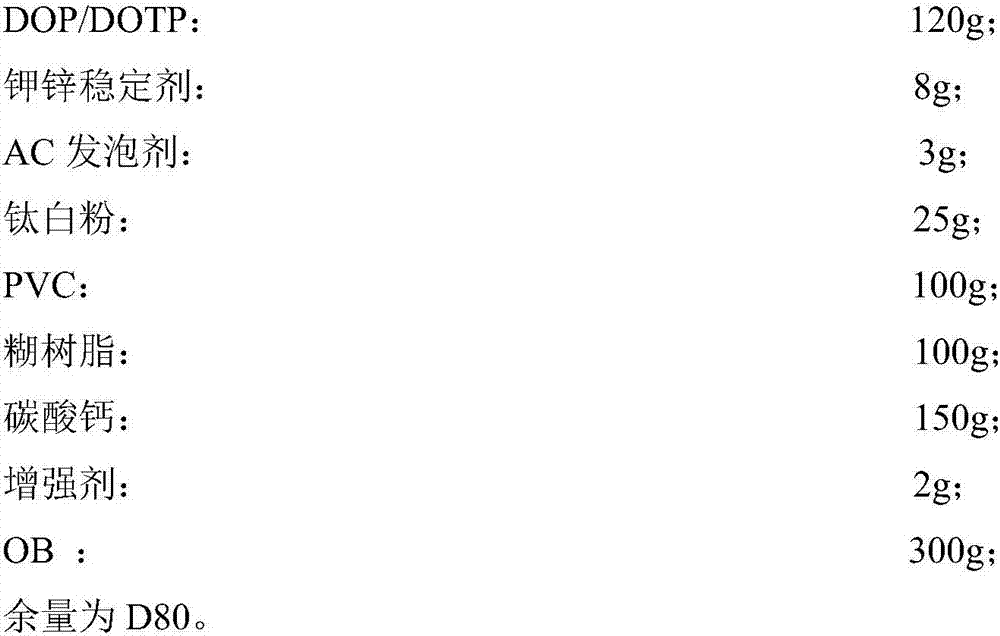

[0039] The slurry is composed of the following components: DOP, potassium zinc stabilizer, AC foaming agent, titanium dioxide, PVC, paste resin, calcium carbonate, reinforcing agent, OB and D80, based on the total mass of the slurry 900g, each component The quality is as follows:

[0040]

[0041]

[0042] A kind of preparation method of gravure fine casing press wallpaper slurry:

[0043] A. Prepare titanium dioxide slurry and AC foam slurry, that is, prepare titanium dioxide slurry and AC foam in two clean barrels according to the ratio of titanium dioxide: DOP = 2: 1 and AC foaming agent: DOP = 2: 1 For foaming slurry, use a mixer to stir the titanium dioxide slurry and AC foaming slurry to a completely dispersed state;

[0044] B. Transport the titanium dioxide slurry and AC foaming slurry fully stirred uniformly in step A to a three-roller grinder for grinding. After grinding, measure the fineness of the titanium dioxide slurry and AC foaming slurry with a fine gau...

Embodiment 2

[0049] The slurry is composed of the following components: DOTP, potassium zinc stabilizer, AC foaming agent, titanium dioxide, PVC, paste resin, calcium carbonate, reinforcing agent, OB and D80.

[0050] According to the total mass of slurry 900g, the mass of each component is as follows:

[0051]

[0052]

[0053] A kind of preparation method of gravure fine casing press wallpaper slurry:

[0054] A. Prepare titanium dioxide slurry and AC foam slurry, that is, prepare titanium dioxide slurry and AC foam in two clean barrels according to the ratio of titanium dioxide: DOTP=2:1 and AC foaming agent: DOTP=2:1 For foaming slurry, use a mixer to stir the titanium dioxide slurry and AC foaming slurry to a completely dispersed state;

[0055] B. Transport the titanium dioxide slurry and AC foaming slurry fully stirred uniformly in step A to a three-roller grinder for grinding. After grinding, measure with a fineness gauge, the fineness of the titanium dioxide slurry and AC f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com