Low-voltage TVS device with an ultralow electric leakage level and manufacturing method thereof

A manufacturing method and horizontal technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as product reliability reduction, malfunction, uncontrolled leakage, etc., and achieve simple process flow and low leakage current value low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The manufacturing method of the low-voltage TVS device with ultra-low leakage level of the present invention comprises the following steps:

[0032] 1) Take silicon single wafer, requirements: ρ=0.001-0.01 Ω·㎝, silicon single wafer thickness t=(200~300)±5 um.

[0033] 2) Silicon single wafer is polished or chemically etched with a polishing machine: use HF, HNO2, HAC solution to acid-etch the silicon wafer, and then use CMP to polish the surface of the silicon wafer. The thickness of the silicon wafer after completion is t=(170~270 )±5um.

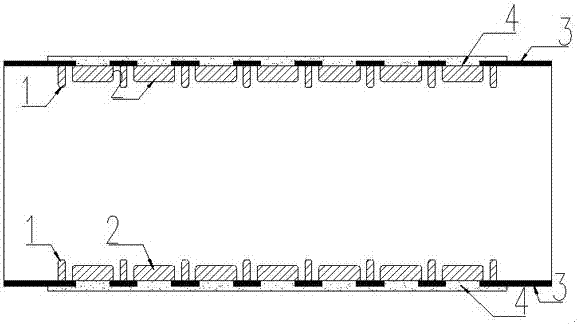

[0034] 3) Oxidation: Oxidize at a temperature of 1140±20°C for 4.0±1h to grow an oxide layer (3) with a thickness of 1.0-1.5um.

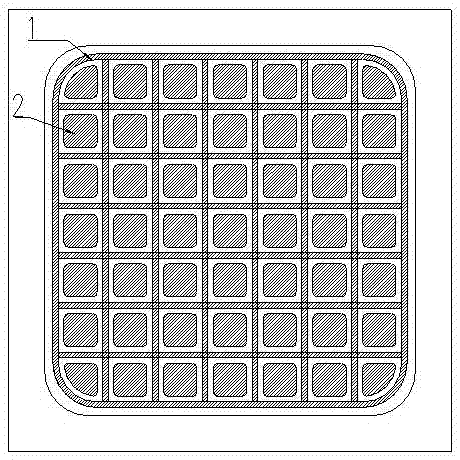

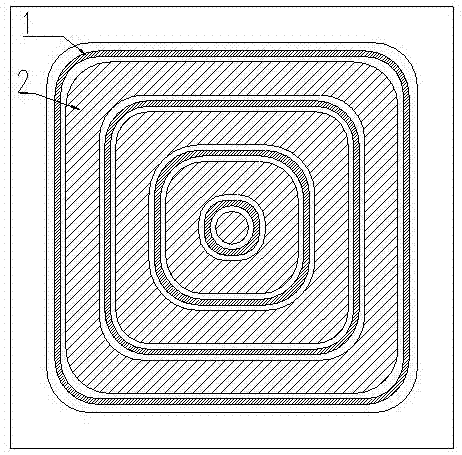

[0035] 4) Double-sided lithography N+ gettering area 1: The longitudinal structure has a short-circuit hole. Using a double-sided lithography machine, align the upper and lower photolithography plates, and place the silicon wafer in the middle of the two photolithography plates. Simultaneous exposure; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com