Low power consumption power capacitor fast discharge device

A technology of power capacitors and discharge devices, which is applied in the direction of output power conversion devices, circuit devices, electrical components, etc., can solve problems such as inability to track compensation in real time, long discharge time, overcompensation, etc., to avoid insulation damage and clutter Effects of interference, ensuring safe operation, and slowing down the waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

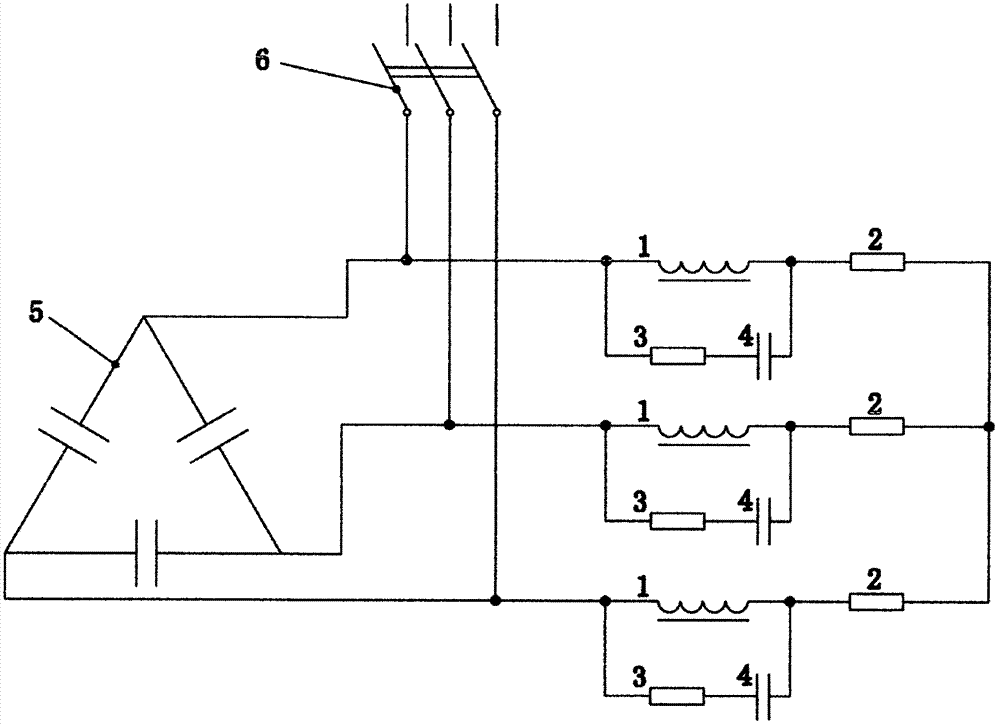

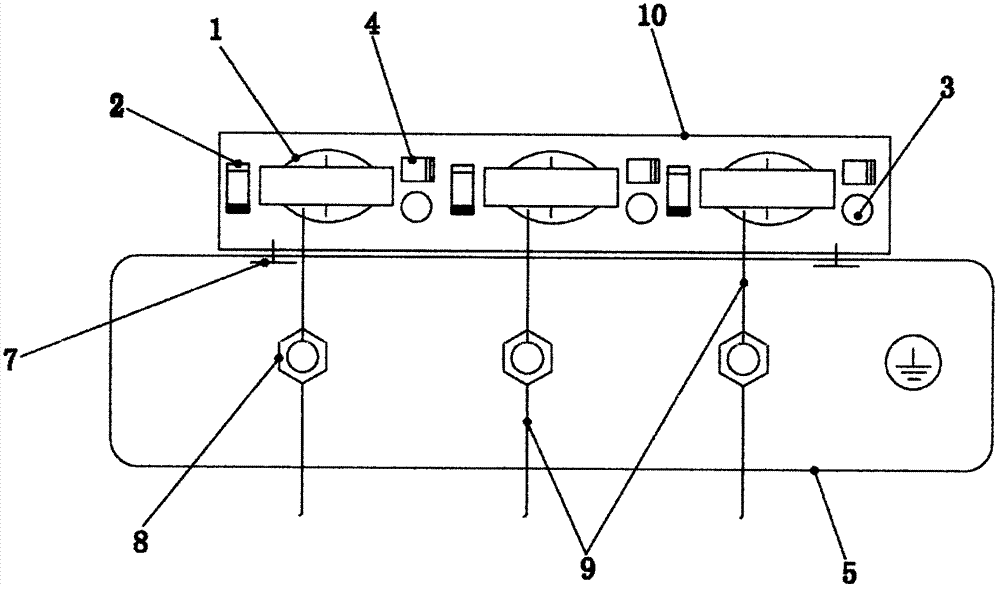

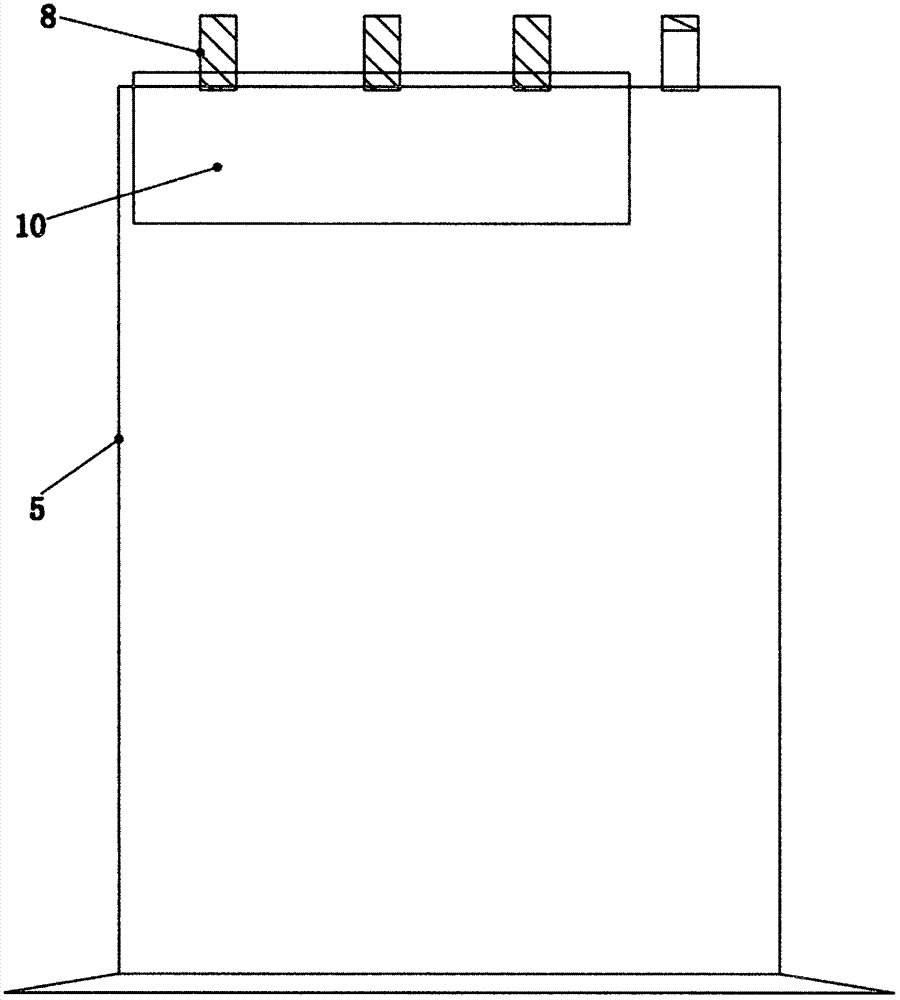

[0031] see figure 2 , image 3 , the specific embodiment adopts the following technical solutions: it includes a choke coil 1, a discharge resistor 2, an absorbing resistor 3, an absorbing capacitor 4, a three-phase power capacitor bank 5, a switching switch 6, a discharge device hook 7, and capacitor bank wiring Pile 8, connecting wire 9 and discharge device outer box 10, RC resistance-capacitance overvoltage absorber composed of choke coil 1, absorbing resistor 3, and absorbing capacitor 4 are connected in parallel and then connected in series with discharging resistor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Dc resistance | aaaaa | aaaaa |

| Coil turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com