Method for preparing portable rectangular flexible low voltage driving electric heating film

A low-voltage driving, electric heating film technology, applied in the direction of ohmic resistance heating, electric heating devices, heating element materials, etc., can solve the problems of limited heating power, high power consumption, display brightness, color difference, resolution and other display characteristics. Achieve the effect of low cost, simple structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

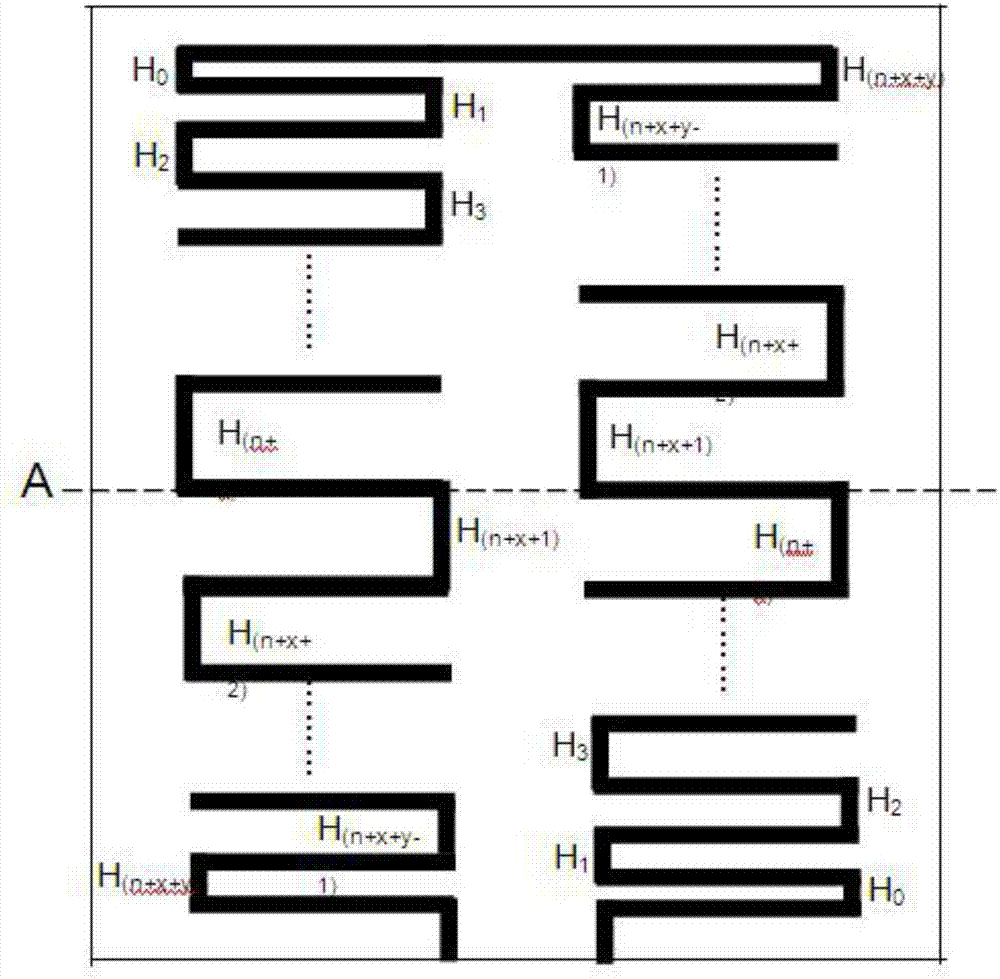

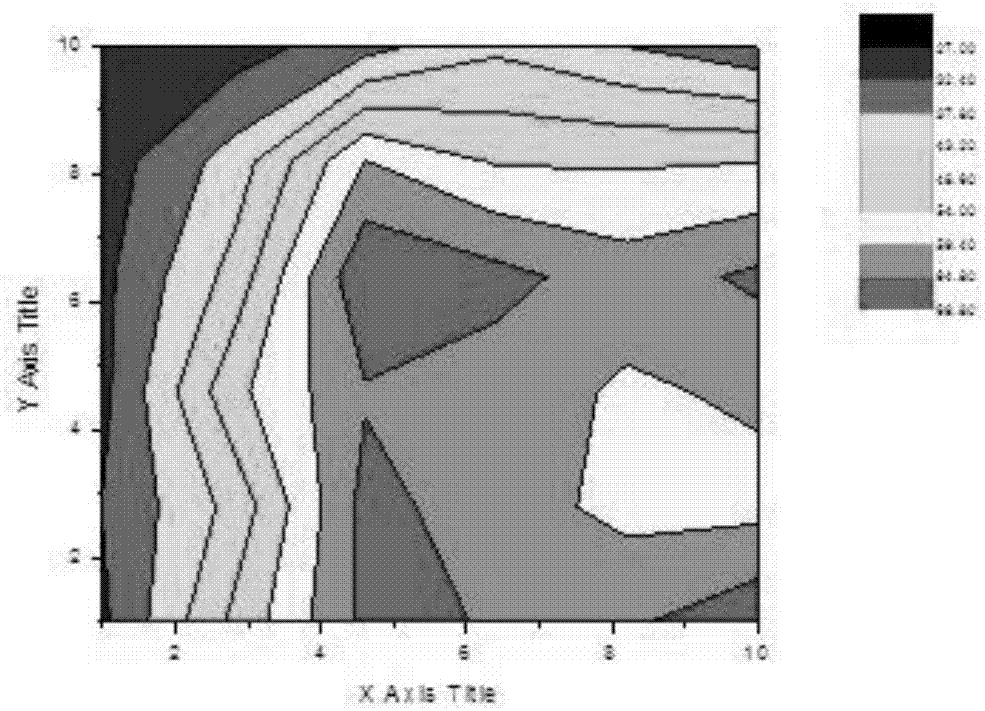

[0022] A flexible electric heating film is designed for a PLC liquid crystal display with a size of 62mm×105mm. The electrode arrangement is as follows: figure 1 shown. The substrate material is 62mm×105mm PET, and the width of the electrode line is 2mm. First print a layer of silver carbon paste with graphene added on PET, the amount of graphene added is 1%; after drying, overprint a layer of silver carbon paste with carbon nanotubes added on top of the existing electrode, carbon The addition of nanotubes is 1.5% and baked at a low temperature of 150 degrees Celsius for 1 hour. High thermal conductivity transparent silica gel is selected, and a protective glue of about 5um is formed on the surface of the electrode through a spin-coating process. Connect the electrode with the control circuit to apply a DC voltage of 5V. After 10 minutes of continuous power on, the infrared imaging of the electrode is measured as follows: image 3 As shown, the average temperature rise of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com