Compounded nozzle button type gas-liquid separation device

A gas-liquid separation device, hood-type technology, applied in the field of wet flue gas desulfurization equipment, composite hood-type gas-liquid separation device, can solve the problem of reducing the solid content and pH value of the slurry, increasing the consumption of absorbent, reducing the secondary Issues such as desulfurization efficiency of stage circulation, to achieve the effect of improving desulfurization efficiency, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

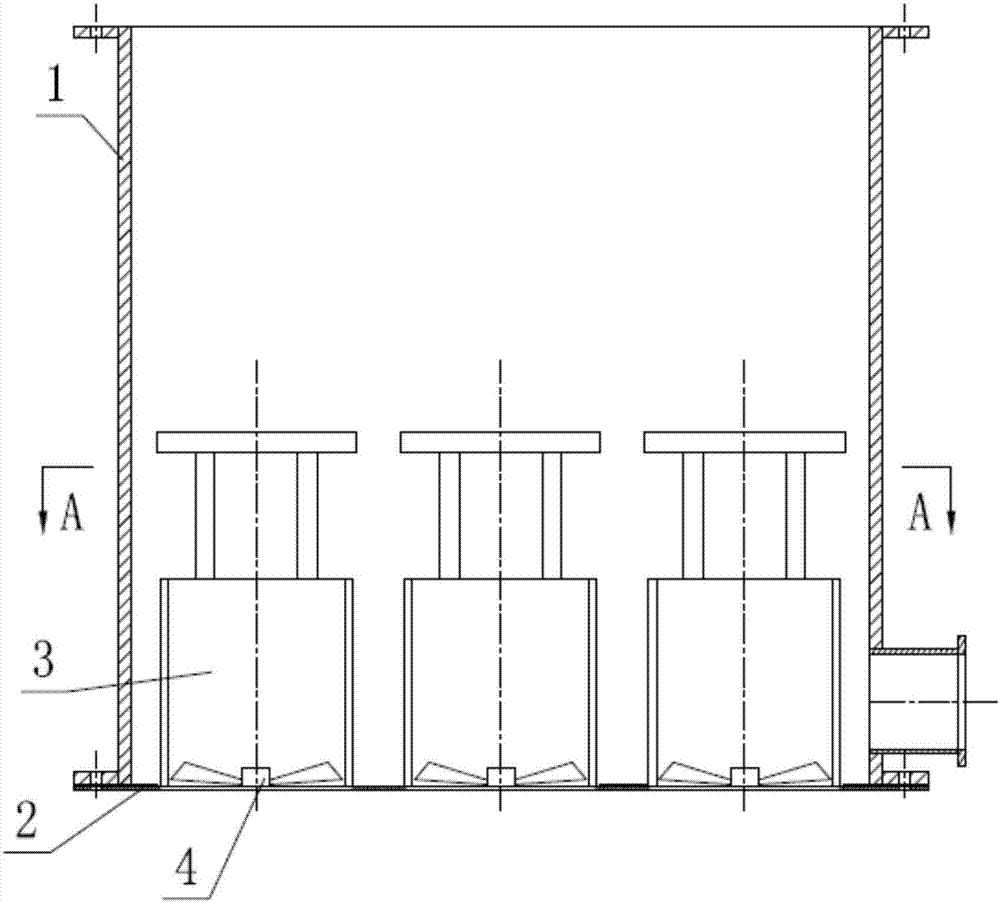

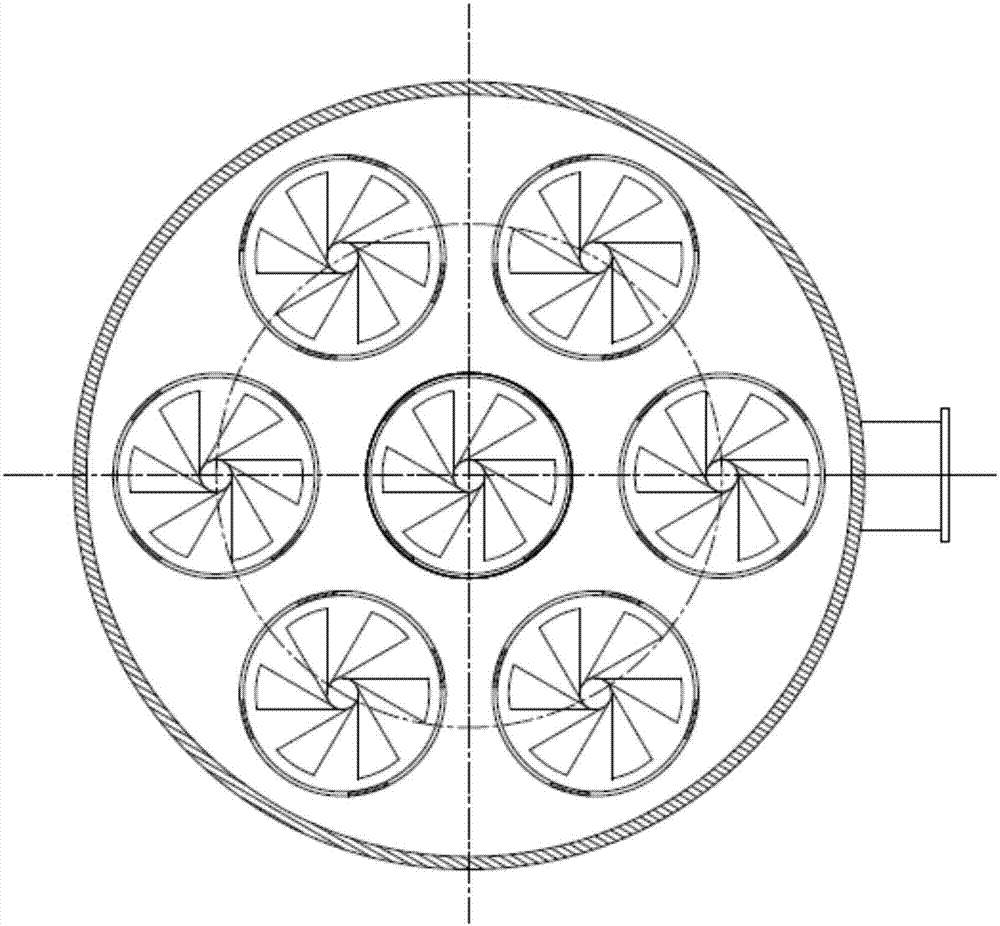

[0022] Such as figure 1 and figure 2 As shown, in one embodiment, a kind of composite hood type gas-liquid separation device is provided, comprising:

[0023] The channel 1 and the sealing plate 2, the sealing plate 2 closes the lower opening of the channel 1; the sealing plate 2 has several circulation holes;

[0024] A number of hoods 3 covering the flow holes; the hood includes a cylinder body and a top plate, the top plate closes the upper opening of the cylinder body, and the upper part of the cylinder body is provided with a number of evenly distributed grid-shaped holes; the inner side of the lower part of the cylinder body is provided with a blade type swirl plate 4.

[0025] Channel 1 is provided with at least one liquid collecting port. In this embodiment, the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com