Laser texturing optical system based on chopping reflectors and galvanometers

An optical system and laser texturing technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unbalanced light splitting, poor consistency of texturing points, limited processing capacity, etc., and achieve a wide range of applications , good system stability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

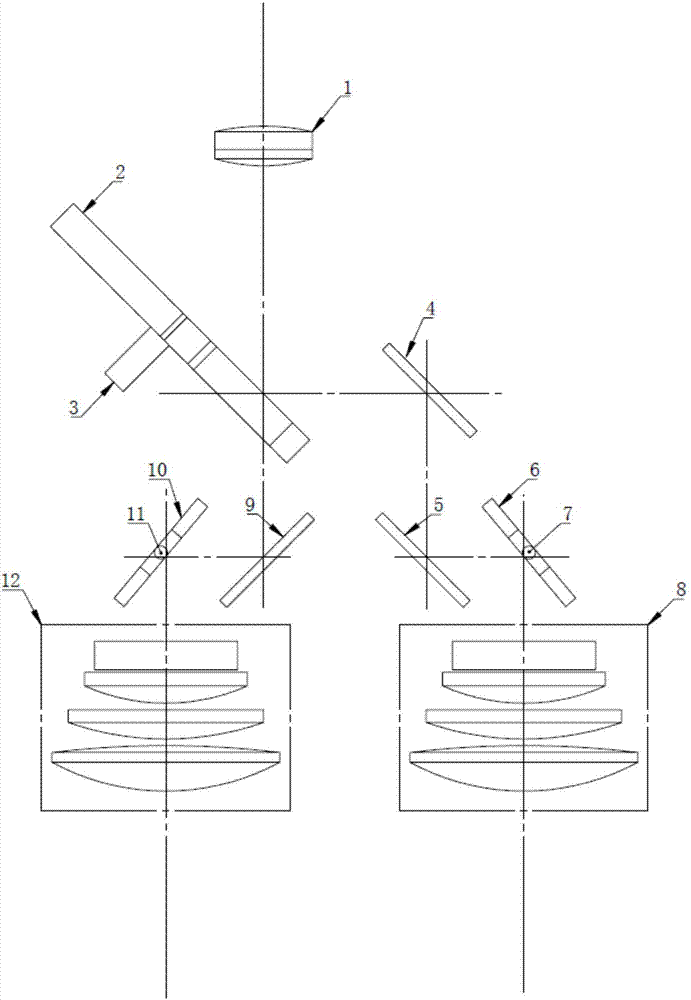

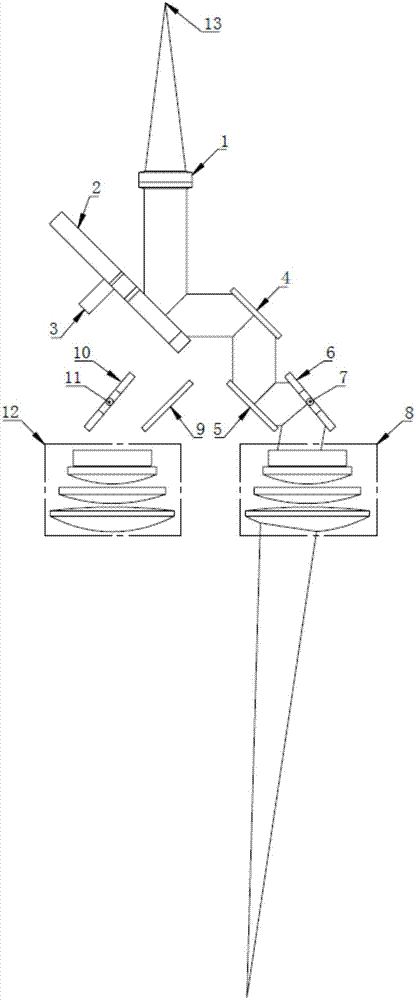

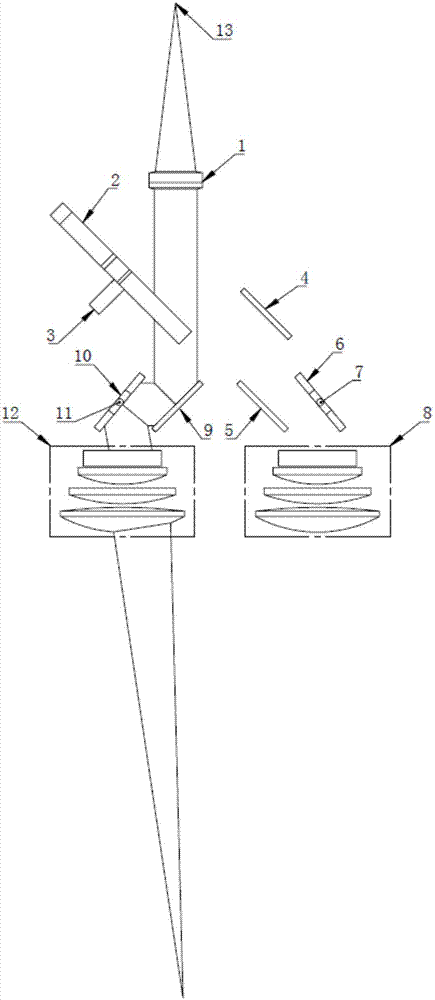

[0025] Such as figure 1 , figure 2 with image 3 As shown, the present specific embodiment adopts the following technical solutions: a kind of optical system based on chopper mirror and vibrating mirror laser texturization, including: pulsed fiber laser beam 13, also includes aberration-eliminating collimator group 1, chopper reflection mirror 2, chopping mirror rotating shaft 3, first reflecting mirror 4, second reflecting mirror 5, first vibrating mirror 6, first vibrating mirror rotating shaft 7, first f-θ mirror 8, third reflecting mirror 9, first vibrating mirror Two vibrating mirrors 10, the second vibrating mirror shaft 11 and the second f-θ mirror 12; an aberration-eliminating collimating mirror group 1 is provided directly below the pulse fiber laser beam 13; the aberration-eliminating collimating mirror A chopper reflector 2 is arranged on the left side below the group 1; a first reflector 4 is provided on the right below the aberration-eliminating collimator grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com