Automatic strip deviation rectifying system

An automatic rectification and strip technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low rectification accuracy, frequent reciprocating motion of the actuator, and large mechanical loss, and achieves high rectification accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

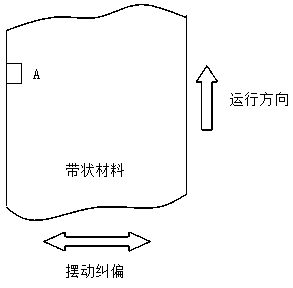

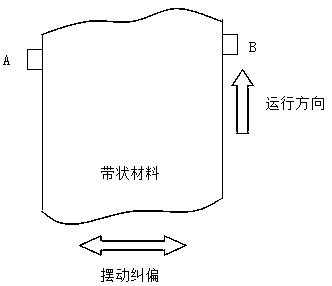

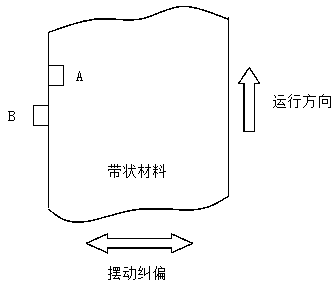

Image

Examples

Embodiment Construction

[0019] Control attached Figure 4 , A strip automatic correction system, its structure includes a microcontroller, sensor module, A photoelectric isolation, B photoelectric isolation, human-computer interaction module, stepper motor driver, relay module, wireless transmission module; among them, the signal of the sensor module The output terminal is connected to the optically isolated signal input terminal of A, the optically isolated signal output terminal of A is connected to the signal input terminal of the microcontroller, and the signal output terminal of the microcontroller is connected to the optically isolated signal input terminal of B. The first signal output terminal is connected to the signal input terminal of the stepper motor driver, the B photoelectrically isolated second signal output terminal is connected to the signal input terminal of the relay module, and the first signal input and output terminal of the microcontroller is connected to the human-computer inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com