System and method for preparing reducing gas for gas-based shaft furnace

A gas-based shaft furnace and preparation system technology, applied in the field of iron and steel metallurgy, can solve the problems of unmatched subsequent utilization processes, high gasifier pressure, waste of coke oven gas, etc., and achieves flexible and adjustable gas components and product gas quality. Good, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

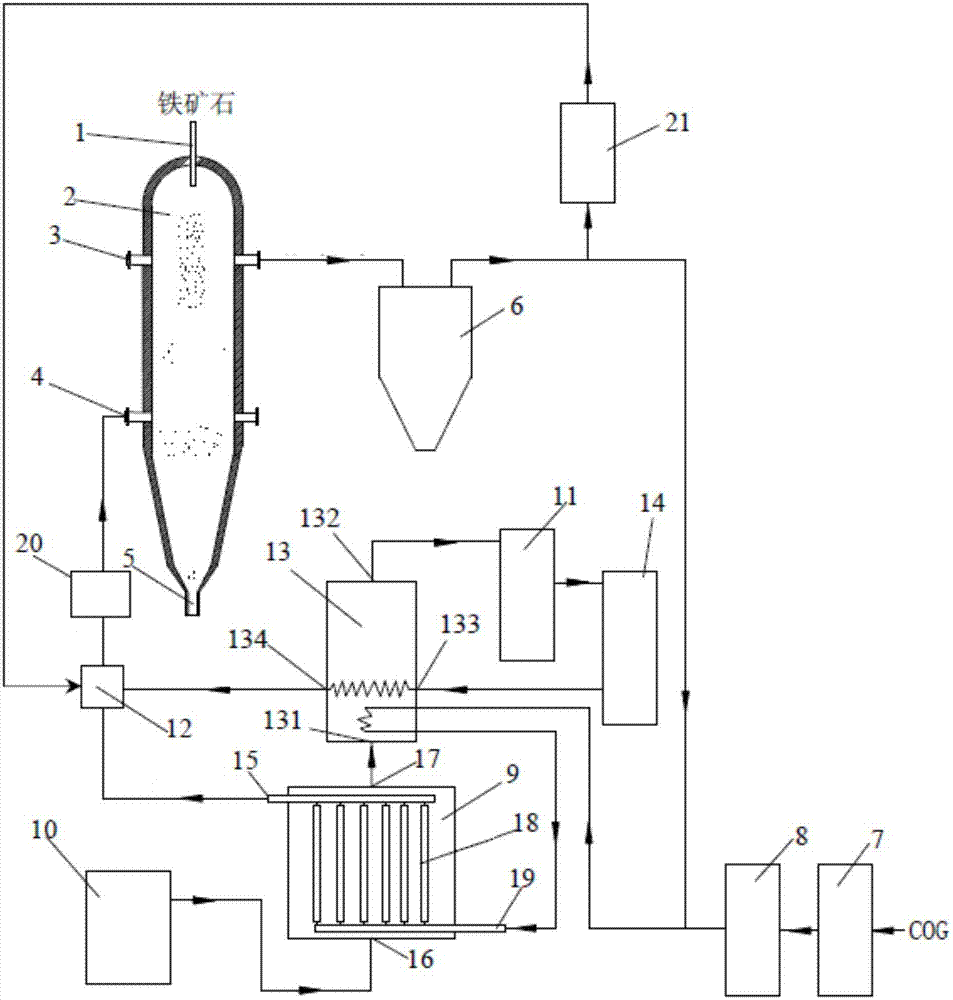

[0046] This embodiment provides a gas-based shaft furnace reduction gas preparation system and method, please refer to figure 1 , which is a schematic diagram of the preparation system of this embodiment, the preparation system includes a gas-based shaft furnace 2, a gas-based shaft furnace top gas scrubber 6, a top gas decarburization device 21, a coke oven gas purification device 7, a coke oven gas Desulfurization device 8, reformer 9, coal gasifier 10, heat recovery device 13, synthesis gas dedusting device (dry dedusting device 11), synthesis gas desulfurization and decarbonization device 14, mixer 12 and heating device 20;

[0047] The furnace body of the gas-based shaft furnace 2 is provided with an iron ore feed inlet 1, a direct reduced iron outlet 5, a reducing gas inlet 4 and a top gas outlet 3; the top gas outlet 3 is connected to the gas-based shaft furnace The inlet of furnace top gas scrubber 6 is connected;

[0048] The reformer 9 includes an airtight shell, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com